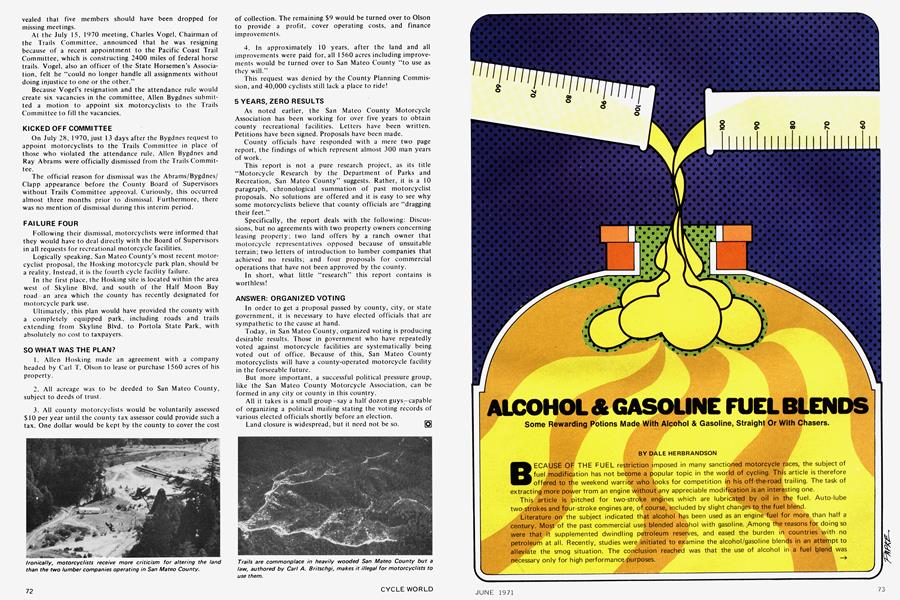

ALCOHOL & GASOLINE FUEL BLENDS

Some Rewarding Potions Made With Alcohol & Gasoline, Straight Or With Chasers.

DALE HERBRANDSON

BECAUSE OF THE FUEL restriction imposed in many sanctioned motorcycle races, the subject of fuel modification has not become a popular topic in the world of cycling. This article is therefore offered to the weekend warrior who looks for competition in his off-the-road trailing. The task of extracting more power from an engine without any appreciable modification is an interesting one.

This article is pitched for two-stroke engines which are lubricated by oil in the fuel. Auto-lube two-strokes and four-stroke engines are, of course, included by slight changes to the fuel blend.

Literature on the subject indicated that alcohol has been used as an engine fuel for more than half a century. Most of the past commercial uses blended alcohol with gasoline. Among the reasons for doing so were that it supplemented dwindling petroleum reserves, and eased the burden in countries with no petroleum at all. Recently, studies were initiated to examine the alcohol/gasoline blends in an attempt to alleviate the smog situation. The conclusion reached was that the use of alcohol in a fuel blend was necessary only for high performance purposes.

Both ethyl alcohol and methyl alcohol have been carefully studied in the dyno room. A tremendous amount of data was compiled in the period between 1920 and 1940. Results show that the poisonous methyl alcohol is preferred over the drinkable ethanol as far as a racing fuel is concerned. Thus, when alcohol is mentioned further in this article, it is methyl alcohol.

ENGINE PERFORMANCE

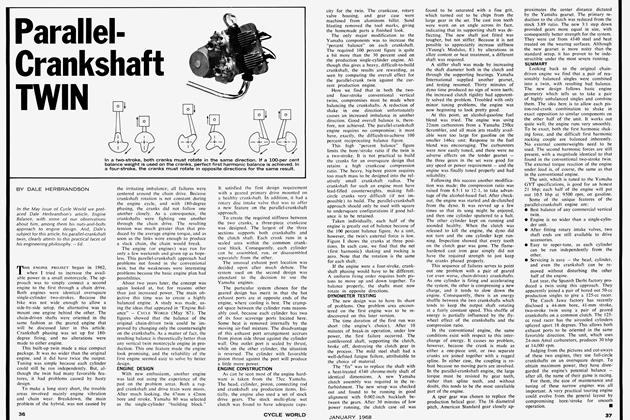

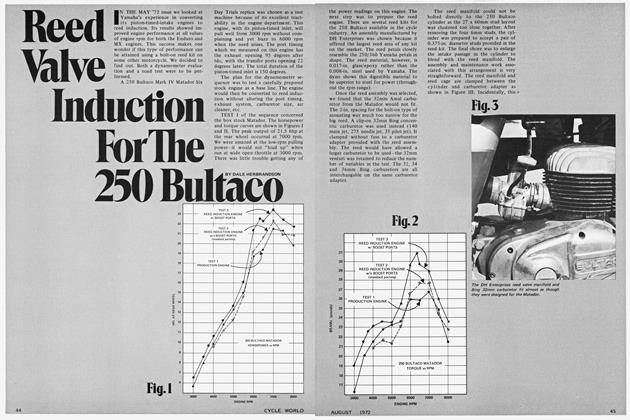

Before we examine the alcohol blends in detail, let s first look at an actual engine test. The graph below shows the effect of substituting methanol for gasoline in a 100-cc, reed valve, two-stroke engine.

The curve for the alcohol-based fuel shows a power increase of almost 10 percent over gasoline. Note that the spark timing and compression ratio were optimized for gasoline. More spark lead and compression would have shown a further gain for the alcohol blend. Although 10 or 12 percent is not a large boost in power, it is rather comforting to know that it's available by simply tipping the can and then adjusting the carburetor jetting.

One might expect that, to produce such a power increase, methanol must be a high energy fuel. Actually, alcohol is a relatively poor fuel. Given an equal volume or weight burned in air, gasoline generates over twice the BTUs per pound of fuel.

Alcohol's chemical makeup causes the fuel to burn extremely lean in a carburetor jetted for gasoline. The excess

oxygen in the lean mixture accrues from the fact that methanol is 50 percent oxygen by weight. To maintain a stoichiometric (chemically correct) air/fuel ratio with methanol, the fuel flow must increase by a factor of 2.3!

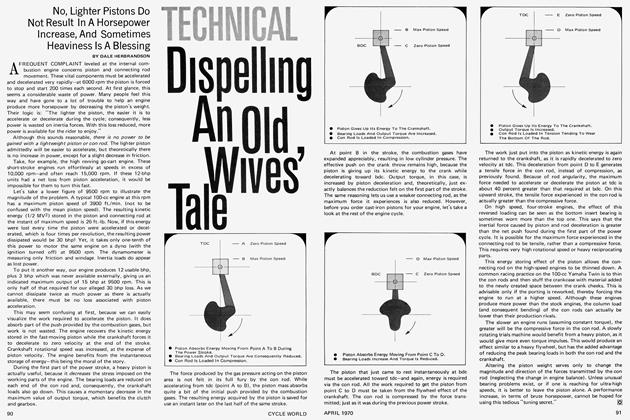

An engine fueled with gasoline usually produces its peak output when 20 percent excess fuel is used. Alcohol fuels, on the other hand, continue to increase engine output up to a mixture that is 40 percent richer than stoichiometric. This very rich alcohol mixture is quite inefficient, as it is accompanied by incomplete burning of the charge. This fact points out the air/fuel tolerance of alcohol-based fuels. The graph at right shows the general shape of the mixture curve at a given engine rpm.

Remember that a correct air/fuel ratio of alcohol is 2.3 times that of gasoline. At 40 percent excess fuel, alcohol requires almost three times the fuel consumption to obtain the same engine output that is available with gasoline at a 20 percent over-rich condition.

The increased power output available from methanol cannot be attributed to the energy of the fuel. The power increase comes from the cooling effect produced by the oxygen-bearing fuel.

VAPORIZATION

In comparison to gasoline, methanol has a very high latent heat of vaporization. Per pound of fuel, methanol requires over three times as much heat for conversion from liquid to a vapor. Multiply this number by the increased fuel flow required and the result is a pronounced cooling effect on the

air/fuel mixture. Cooling is easily noticeable in an alcohol engine, as the carburetors are very cool, and may even become frosty.

Increased output from engines using methanol has generally been explained as a result of the chilling of the air/fuel charge. The logic is that a cool mixture would be more dense, and the engine would consume an increased mass of charge, with an increased volumetric efficiency.

The chilled charge hypothesis applied to methanol cannot be substantiated by airflow rate measurements. The results usually reported show only a very small increase in volumetric efficiency when using alcohol or alcohol/gasoline blends. Various researchers have concluded that the major power increase is due to the reduced work required on the compression stroke.

Since high performance engines do not supply carburetorheat to vaporize the fuel, the methanol enters the engine in a partially vaporized state. During compression in the cylinder, the wet air/fuel mixture vaporizes (due to the heat of compression) and greatly reduces the temperature of the charge. This absorption of heat retards the pressure rise (which lowers the work of compression) and also reduces the tendency to detonate.

ALCOHOL/GASOLINE BLENDING

The first part of this article pointed out that methanol can be used to obtain a respectable power increase, but only at the expense of high fuel consumption. We can easily trade lower performance for better economy by mixing the two fuels.

Alcohol and gasoline are completely miscible in all proportions-providing that the alcohol is anhydrous (water free). Even small additions of water to the blend will cause separation. For example, the water that can be tolerated in a 25 percent alcohol/75 percent gasoline blend at room temperature is about 1 percent. If an additional 1 percent is added, the mixture will become cloudy and finally separate into two distinct layers (the water is absorbed in the alcohol, and both settle to the bottom). Separation is also promoted by lowering the temperature. Blending agents can be added to stabilize the mixture. Among these are acetone, butyl alcohol, and benzol (a commercial purity of benzene). For this reason the gasoline/alcohol fuels also contain small percentages of benzene and/or acetone.

The aromatic compound, benzene, is, incidentally, a respectable motor fuel. It produces an output identical to gasoline for a stoichiometric air/fuel ratio. Benzene has a higher latent heat content than gasoline; track testing has shown that when benzol is blended with gasoline the engine operating temperature is reduced.

THE GASOLINE-BASED FUELS

The first blend below can be used in a stock carburetor without modification. The stock spark plug and jetting can be used. The engine should have the same output as on gasoline; the only bonus is that the engine should run somewhat cooler than before. All percentages are listed on a volume basis. —*

By adding alcohol to the fuel as shown in blend 2 we come up with an interesting combination. Not too much work is required to tune the replaceable main jets in the carburetor (it is a requirement). The blend will work well with stock compression and standard spark lead. There will be a noticeable increase in power output, and a large change in the odor of the exhaust. The methanol, and especially the benzene, have a different and somewhat agreeable odor. Blend number 2 is a good place to start. You should use one range colder spark plug as a precaution when tuning.

The next fuel mixture retains some gasoline. Benzene is still required as the mixing agent. Note that the methanol is becoming the predominate ingredient. This blend may require carburetor modification to pass the required fuel flow. The replaceable jets can only be enlarged to a point where they equal the size of another restriction somewhere else in the fuel stream. It could be possible to have an inlet needle that is unable to cope with the demand.

Blend number 3 will produce respectable power over gasoline without drastically altering the driving range of a motorcycle. A trail bike would have around half the driving radius using blend 3 in place of pump gasoline. This is not bad as long as the operator is willing to trade performance for a few more fuel stops.

It should be pointed out that all of the blends in this article are set up for the two-stroke engine. If you want to try these blends in an auto-lube two-stroke or a four-stroke unit, the 4 percent acetone blender and 10 percent lubricant will not be required.

ALCOHOL-BASED FUELS

Before using the following fuels, the user must be aware of a few simple requirements.

First, the carburetor must be modified to pass two to three times the amount of fuel through metering orifices initially set up for gasoline. This will require careful examination of all passages, from the fuel tank to the discharge of the main jet. A knowledge of the metering characteristics of the carburetor is essential.

Even though methanol has an octane rating of almost 100, it will detonate if provoked. Years ago, a mystique was generated about the knock-suppressing tendencies of alcohol. The ideas were accurately formulated in the 1940s when the highest octane gasolines were in the 80 range. With today's high octane gasolines, the effectiveness of methanol as a knock suppressor is not too important.

A cold spark plug is essential for blends 4 thru 7! I have successfully used plugs as cold as Champion N-52R in a fully modified Yamaha 100 Twin. When the warmer NGK 10 plugs

were fitted, the engine immediately went into detonation and burned a piston. The number 10 plug is fairly cold by gasoline standards, but was entirely unacceptable when burning blend number 4.

Ignition timing must be advanced to match the burning rate of the fuel blend; this rate is also influenced by compression ratio. Both methanol and nitro are relatively slow burning. An advance of around 30 degrees before TDC will be required for optimum performance. The compression ratios referenced below are to be measured using the effective stroke (in a two-stroke only) above the exhaust port.

Methanol, acetone, and nitromethane are powerful solvents; they will swell any rubber seals that were compounded for use with gasoline. Especially critical is the Viton-tipped inlet needle used on many carburetors. A metal needle must be fitted in its place.

Blends 5 thru 7 are not recommended as a starting place for the uninitiated. The nitrated fuels are difficult to work with but secure top notch results. If the mixture, spark lead, and spark plug are not correct it is terribly easy to burn a piston. However, if all is in order, blends like number 7 are quite impressive.

ENGINE DEPOSITS

Many researchers have reported that the lower-molecularweight alcohol burns with less soot and deposits than the hydrocarbon gasolines. Methanol appears to be a relatively clean burning fuel. Tests conducted on a four-stroke V-8 by Southwest Research Institute showed that a blend of 75 percent unleaded gasoline and 25 percent alcohol produced only 1/7 the deposit of a commercial leaded gasoline. Our blends 2 and 3 therefore should be well adapted for trail use, as they are not dirty fuels. This cleanliness should promote spark plug life in the prone-to-foul two-stroke engine.

CONCLUSIONS

Methyl alcohol fuel blending offers some distinct advantages over pump gasoline as a high performance fuel. If done correctly, the modification will not harm the engine, and should even promote longevity due to the cleanliness of the brew. Fuel blending is an interesting and rewarding way to pour new life in your present machine. [Ö]