Dispelling An Old, Wives Tale

TECHNICAL

DALE HERBRANDSON

No, Lighter Pistons Do Not Result In A Horsepower Increase, And Sometimes Heaviness Is A Blessing

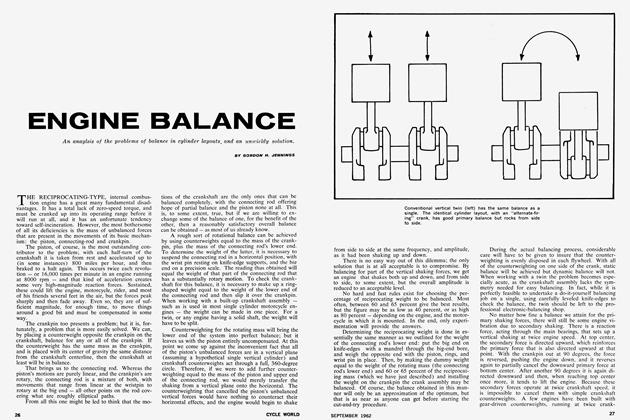

A FREQUENT COMPLAINT leveled at the internal combustion engine concerns piston and connecting rod movement. These vital components must be accelerated and decelerated very rapidly—at 6000 rpm the piston is forced to stop and start 200 times each second. At first glance, this seems a considerable waste of power. Many people feel this way and have gone to a lot of trouble to help an engine produce more horsepower by decreasing the piston's weight. Their logic is: "The lighter the piston, the easier it is to accelerate or decelerate during the cycle; consequently, less power is wasted on inertia forces. With this loss reduced, more power is available for the rider to enjoy."

Although this sounds reasonable, there is no power to be gained with a lightweight piston or con rod. The lighter piston admittedly will be easier to accelerate, but theoretically there is no increase in power, except for a slight decrease in friction. Take, for example, the high revving go-cart engine. These short-stroke engines run effortlessly at speeds in excess of 10,000 rpm-and often reach 15,000 rpm. If these 12-bhp units had a net loss from piston acceleration, it would be impossible for them to turn this fast.

Let's take a lower figure of 9500 rpm to illustrate the magnitude of the problem. A typical 100-cc engine at this rpm has a maximum piston speed of 3900 ft./min. (not to be confused with the mean piston speed). The resulting kinetic energy (1/2 MV2) stored in the piston and connecting rod at the instant of maximum speed is 26 ft.-lb. Now, if this energy were lost every time the piston were accelerated or decel erated, which is four times per revolution, the resulting power dissipated would be 30 bhp! Yet, it takes only one-tenth of this power to motor the same engine on a dyno (with the ignition turned off) at 9500 rpm. The dynamometer is measuring only friction and windage. Inertia loads do appear as lost power.

To put it another way, our engine produces 12 usable bhp, plus 3 bhp which was never available externally, giving us an indicated maximum output of 15 bhp at 9500 rpm. This is only half of that required for our alleged 30 bhp loss. As we cannot dissipate twice as much power as there is actually available, there must be no loss associated with piston acceleration.

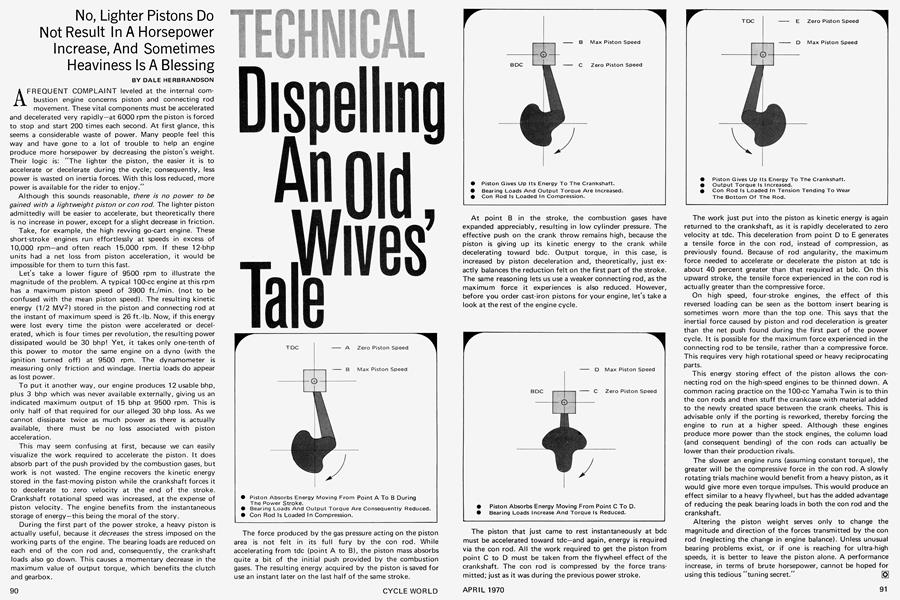

This may seem confusing at first, because we can easily visualize the work required to accelerate the piston. It does absorb part of the push provided by the combustion gases, but work is not wasted. The engine recovers the kinetic energy stored in the fast-moving piston while the crankshaft forces it to decelerate to zero velocity at the end of the stroke. Crankshaft rotational speed was increased, at the expense of piston velocity. The engine benefits from the instantaneous storage of energy-this being the moral of the story.

During the first part of the power stroke, a heavy piston is actually useful, because it decreases the stress imposed on the working parts of the engine. The bearing loads are reduced on each end of the con rod and, consequently, the crankshaft loads also go down. This causes a momentary decrease in the maximum value of output torque, which benefits the clutch and gearbox.

The force produced by the gas pressure acting on the piston area is not felt in its full fury by the con rod. While accelerating from tdc (point A to B), the piston mass absorbs quite a bit of the initial push provided by the combustion gases. The resulting energy acquired by the piston is saved for use an instant later on the last half of the same stroke.

At point B in the stroke, the combustion gases have expanded appreciably, resulting in low cylinder pressure. The effective push on the crank throw remains high, because the piston is giving up its kinetic energy to the crank while decelerating toward bdc. Output torque, in this case, is increased by piston deceleration and, theoretically, just ex actly balances the reduction felt on the first part of the stroke. The same reasoning lets us use a weaker connecting rod, as the maximum force it experiences is also reduced. However, before you order cast-iron pistons for your engine, let's take a look at the rest of the engine cycle.

The piston that just came to rest instantaneously at bdc must be accelerated toward tdc-and again, energy is required via the con rod. All the work required to get the piston from point C to D must be taken from the flywheel effect of the crankshaft. The con rod is compressed by the force trans mitted; just as it was during the previous power stroke.

The work just put into the piston as kinetic energy is again returned to the crankshaft, as it is rapidly decelerated to zero velocity at tdc. This deceleration from point D to E generates a tensile force in the con rod, instead of compression, as previously found. Because of rod angularity, the maximum force needed to accelerate or decelerate the piston at tdc is about 40 percent greater than that required at bdc. On this upward stroke, the tensile force experienced in the con rod is actually greater than the compressive force.

On high speed, four-stroke engines, the effect of this reversed loading can be seen as the bottom insert bearing is sometimes worn more than the top one. This says that the inertial force caused by piston and rod deceleration is greater than the net push found during the first part of the power cycle. It is possible for the maximum force experienced in the connecting rod to be tensile, rather than a compressive force. This requires very high rotational speed or heavy reciprocating parts.

This energy storing effect of the piston allows the connecting rod on the high-speed engines to be thinned down. A common racing practice on the 100-cc Yamaha Twin is to thin the con rods and then stuff the crankcase with material added to the newly created space between the crank cheeks. This is advisable only if the porting is reworked, thereby forcing the engine to run at a higher speed. Although these engines produce more power than the stock engines, the column load (and consequent bending) of the con rods can actually be lower than their production rivals.

The slower an engine runs (assuming constant torque), the greater will be the compressive force in the con rod. A slowly rotating trials machine would benefit from a heavy piston, as it would give more even torque impulses. This would produce an effect similar to a heavy flywheel, but has the added advantage of reducing the peak bearing loads in both the con rod and the crankshaft.

Altering the piston weight serves only to change the magnitude and direction of the forces transmitted by the con rod (neglecting the change in engine balance). Unless unusual bearing problems exist, or if one is reaching for ultra-high speeds, it is better to leave the piston alone. A performance increase, in terms of brute horsepower, cannot be hoped for using this tedious "tuning secret."

View Full Issue

View Full Issue

More From This Issue

-

Departments

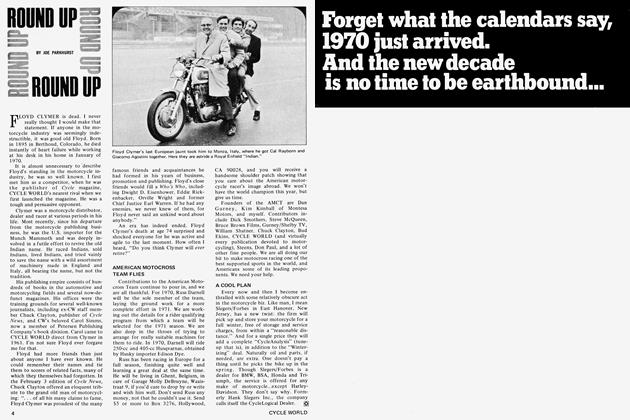

DepartmentsRound Up

April 1970 By Joe Parkhurst -

Letters

LettersLetters

April 1970 -

Departments

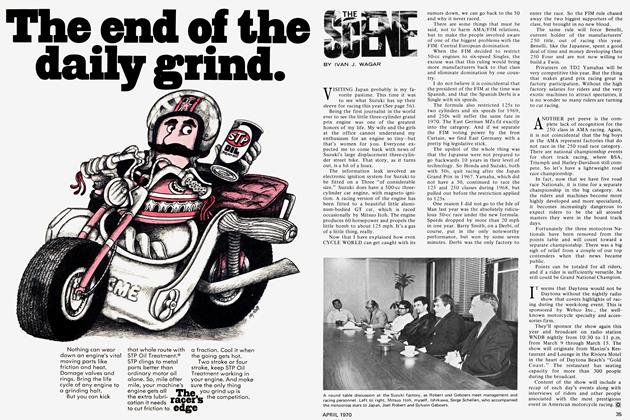

DepartmentsThe Scene

April 1970 By Ivan J. Wagar -

Departments

DepartmentsThe Service Department

April 1970 By John Dunn -

Features

FeaturesA Mind of Its Own

April 1970 By Bob Ebeling -

A Cycle World Exclusive

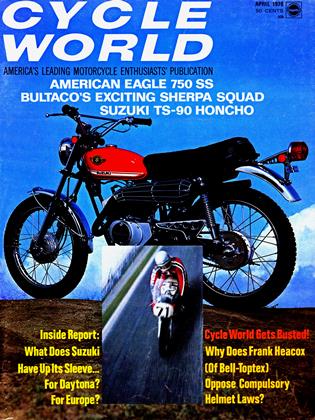

A Cycle World ExclusiveWhat Does Suzuki Have Up Its Sleeve?

April 1970 By Ivan J. Wagar