THE SERVICE DEPARTMENT

JOHN DUNN

HONDA ELECTRICAL TRICK

I always thought it was next to impossible to start my Honda with a dead battery. When I took it to a dealer he showed me a trick. By turning the light switch to an in-between setting, he was able to get the bike running, although the battery was all the way down. I thought I'd pass the tip along, but would be very interested to know just what is happening in the circuitry to make this emergency measure possible.

Harry Pepperell Barre, Mass.

It is not possible to do this with all Hondas. In fact it applies only to early Superhawk and Scrambler models. When the lights are switched on, an additional charging coil is brought into action. The dip switch on these earlier models had a dead spot midway between the low and high beam positions. When the switch is in the midway position, neither beam will work; thus the additional current is available for ignition purposes. California law now forbids this type of dip switch for obvious reasons.

RELUCTANT KAWASAKI

My 1969 Kawasaki 350 is reluctant to rev over 6000 rpm until after a few miles on the freeway. After that, it will rev up to 8500 with no complaint. How can I get correct performance without a freeway jaunt?

Kim Stocksdale

Berkeley, Calif.

It sounds as though your 350 Kawasaki is loading up when driven at moderate speed on surface streets. Many twocycles tend to do this if ridden too slowly. The problem is an excessive accumulation of oil and gasoline (mainly oil) in the crankcase. Initially when the machine is driven a bit harder, it will not rev due to the poor combustion characteristics of an excess of oil in the air/fuel mixture entering the combustion chamber. After the machine has been ridden hard for a short while, the accumulation of oil in the crankcase is used up; normal combustion follows, thereby permitting the engine to operate efficiently and to rev freely.

If this is the case, the exhaust will produce medium to large clouds of smoke during hard riding until it has cleaned out. Using a spark plug that is too cold will accentuate the problem, particularly if the machine is ridden primarily at low engine speeds.

MOTORCYCLE DYNAMOMETER

I am interested in operating a diagnostic center for motorcycles. A chassis dynomometer which could handle a wide variety of two-wheelers would be necessary to such a business. Where could I purchase this instrument or where could I get the necessary bits and pieces to make one?

Dean P. Campbell Glynco, Ga.

I do not know of a source in this country for a chassis dynamometer for single-track vehicles (motorcycles). However, recently a company started manufacture and marketing of fairly inexpensive engine dynamometers; capacities range from 10 to 600 bhp. All are water absorption units that apparently operate satisfactorily when hooked up to a domestic water supply, such as a garden hose. Prices range from (Continued on page 44) approximately $500 to $3500 ready to run with normal instrumentation and control systems. In addition to the dynamometer, a fuel/air measuring device is offered. This device would prove extremely useful to the serious tuner as it gives direct indications of volumetric (air flow) and thermal efficiencies. I have not had direct experience with this equipment, but I believe the designs are based on first class principles, and that one of these units could almost certainly be adapted for use as a chassis dynamometer for motorcycles. The name and address of the company is: Go-Power Systems, 1880 Embarcadero Road, Palo Alto, CA 94303.

Continued from page 42

HARLEY FUEL PROBLEM

My 1965 XLH with L&L carburetor seems to run out of gasoline under sustained acceleration. After extensive modifications, which included boring out the carburetor and adding a float bowl spacer, the engine runs stronger at all speeds-but still runs out of gas. All routine checks for obstructions, etc., have been negative.

I know of two possible cures: 1) a diaphragm carburetor or 2) installing a tire valve stem in the tank cap and pressurizing the fuel tank to about 3 psi. Both approaches seem to be running away from the problem rather than curing it. After all, Sportsters ran at the drags for years with the L&L. There's got to be some trick involved here. What is it?

J.G. Krol Anaheim, Calif.

Sorry, but I know of no trick. If there is a specific problem with respect to the XLH running short of gas during acceleration, perhaps an enlightened reader will inform us.

Are you sure that fuel starvation is the problem? The problem could be caused by an electrical or a mechanical malfunction. If the spark plugs are too warm, failure may result during high engine load. An ignition system defect or a problem in the valve train could produce similar symptoms. Check for broken or tired valve springs.

It is also possible that a valve could be sticking slightly in its guide when the engine temperature reaches a certain level. Also, excessive carbon deposits often cause sticking exhaust valves. A temporary remedy is to squirt a small quantity of upper cylinder lubricant into the intake while the engine is running. It will be necessary to rev the engine in order to burn off the excess lubricant, and the exhaust will smoke excessively during this treatment. Check that the gasoline tank is properly vented. A restriction would create a slight vacuum in the tank, thereby reducing fuel flow.

(Continued on page 46)

Continued from page 44

NO IDLE TALK

I have been experiencing trouble with my 1968 CB 350 Honda lately. It all started with an annoying rattle that appeared to be coming from the valves or cam chain. The engine would refuse to idle below 2000 rpm when the throttle was closed. Then, after a time it would drop down to 1200 rpm. I tried adjusting the carburetors but could not get a reliable idle. If I set the idle at 1000 rpm with the engine hot, it would idle OK for awhile, then suddenly stop. In an attempt to cure the rattle I adjusted the valves. Although I adjusted them to the book (0.002 in.), they rattle even worse now. Also, the engine tends to run away; revs gradually increase with the throttle shut. What is the trouble?

F.R. Clues New Orleans, La.

You have made matters worse by diagnosing the initial problem incorrectly. I believe that the rattle was caused by a sticking ignition advance mechanism. The weights became dry due to lack of lubrication, then rust formed from condensation, causing the weights to stick and not return to the retard position. Having the weights stuck partially open would cause the idle speed to be high. Vibration, on occasion, would loosen the sticking weights and then the engine speed would drop to the correct idle, which should be approximately 1000 rpm. The advance mechanism weights can be freed by removing the contact breaker back plate and squirting them (the weights) with a small quantity of light oil. There are small access holes behind the back plate.

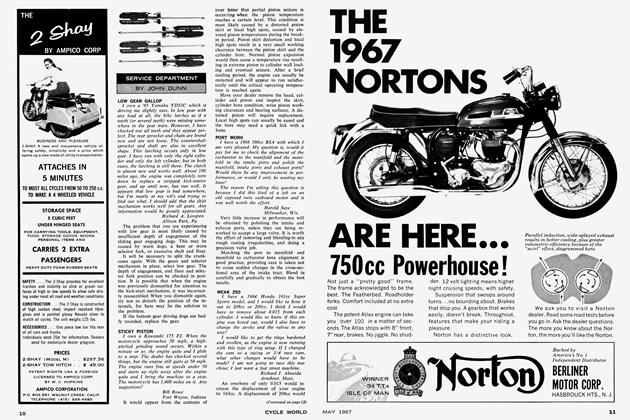

When you adjusted the valves, it is quite likely that you turned one or more of the eccentric adjusting spindles the wrong way. Adjustment can be achieved even with the spindles turned the wrong way. However, the actuating geometry is far from correct, the rocker pad being incorrectly positioned on the valve stem. This will result in excessive valve noise and will cause damage if run for any length of time. I suggest you check this point and readjust accordingly. As shown in the sketches below, the ends of the eccentric spindles are marked and should be in the approximate positions shown when the valves have been adjusted to .002 in. intake and .003 in. exhaust. If the valves are adjusted too tightly, the rpm will tend to increase and run away on idle.

DUCATI: MAGNETO VS. BATTERY

I was planning to buy a Ducati Diana for some time before reading your comments to R. Evans in the October issue of CW. You have raised some doubts. What is the disadvantage of a magneto ignition compared with battery ignition on the Ducati or any motorcycle? I own a 1963 Ducati 125 and have no complaints with the magneto.

Richard C. Ferguson Tacoma, Wash.

Our answer to Mr. Evans in the October issue was not intended to belittle the Diana Mark III. We stated that it is not the world's most tractable touring machine because in order to achieve its high performance qualities, it is not very flexible or easy to start.

The magneto functions very well from an ignition point of view. The difference with respect to coil vs. magneto ignition is that the coil gives its highest voltage at low speed due to the high primary current available from the battery. The magneto, on the other hand, generates its own primary current. This results in low voltage at low engine speed (as when starting) increasing proportionally with engine speed. The hard starting characteristics of the Diana cannot be attributed only to the low magneto output available during cranking speeds. It is just as much due to the high state of tune of the engine. Before chosing the Diana as your next machine, be sure in your own mind whether you want a docile tourer or a highly tuned sportster.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

April 1970 By Joe Parkhurst -

Letters

LettersLetters

April 1970 -

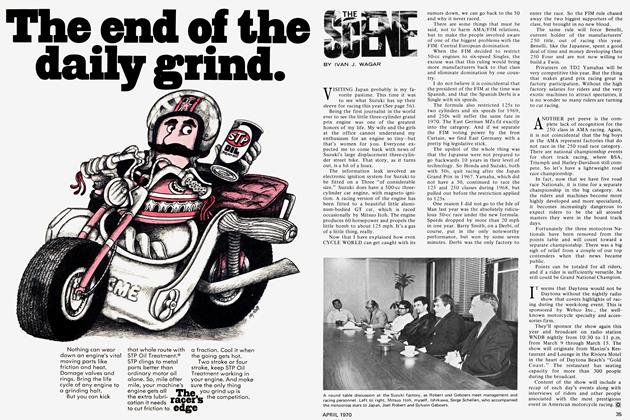

Departments

DepartmentsThe Scene

April 1970 By Ivan J. Wagar -

Features

FeaturesA Mind of Its Own

April 1970 By Bob Ebeling -

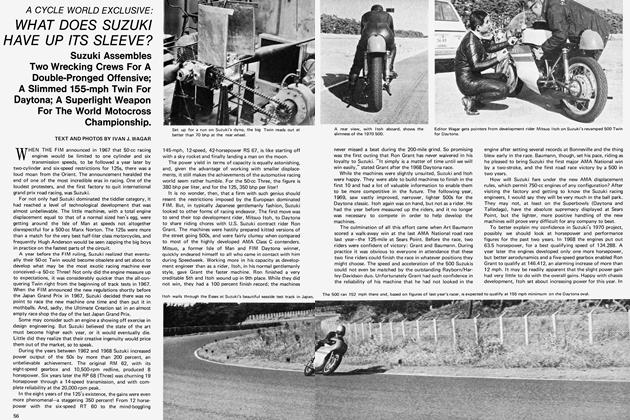

A Cycle World Exclusive

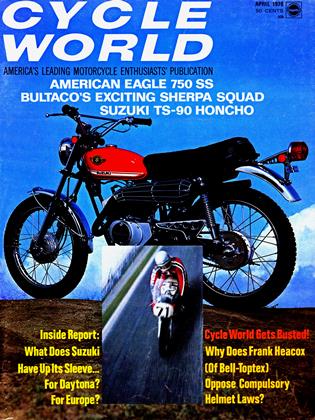

A Cycle World ExclusiveWhat Does Suzuki Have Up Its Sleeve?

April 1970 By Ivan J. Wagar -

Features

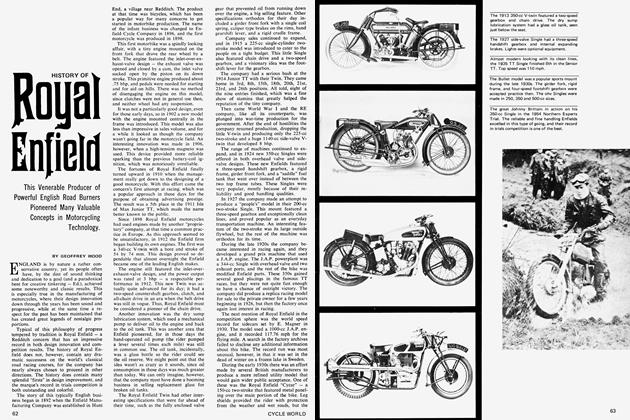

FeaturesHistory of Royal Enifield

April 1970 By Geoffrey Wood