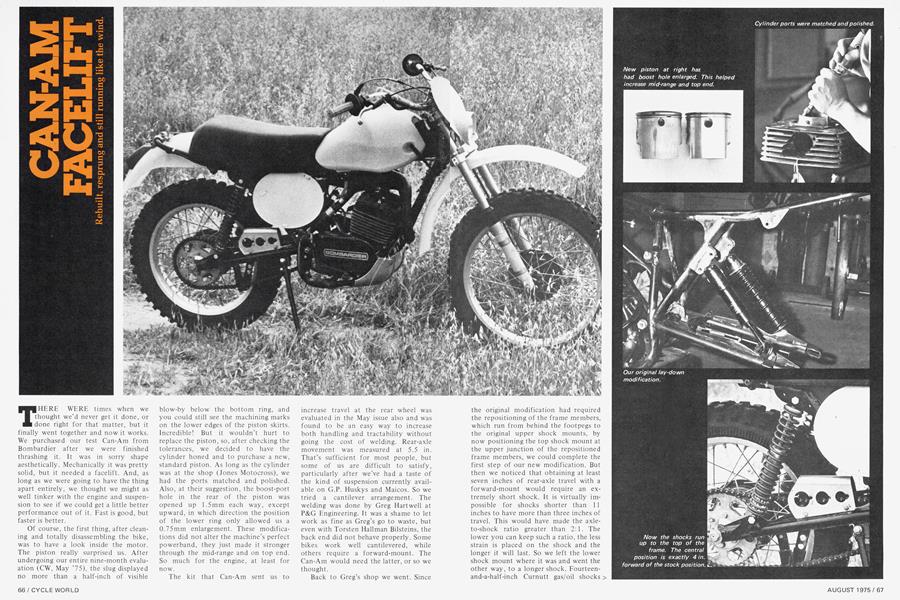

CAN-AM FACELIFT

Rebuilt. resprung and still running like the wind.

THERE WERE times when we

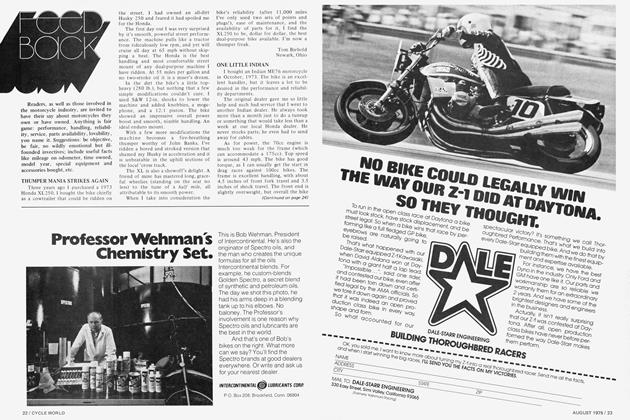

thought we’d never get it done, or done right for that matter, but it finally went together and now it works. We purchased our test Can-Am from Bombardier after we were finished thrashing it. It was in sorry shape aesthetically. Mechanically it was pretty solid, but it needed a facelift. And, as long as we were going to have the thing apart entirely, we thought we might as well tinker with the engine and suspension to see if we could get a little better performance out of it. Fast is good, but faster is better.

Of course, the first thing, after cleaning and totally disassembling the bike, was to have a look inside the motor. The piston really surprised us. After undergoing our entire nine-month evaluation (CW, May ’75), the slug displayed no more than a half-inch of visible blow-by below the bottom ring, and you could still see the machining marks on the lower edges of the piston skirts. Incredible! But it wouldn’t hurt to replace the piston, so, after checking the tolerances, we decided to have the cylinder honed and to purchase a new, standard piston. As long as the cylinder was at the shop (Jones Motocross), we had the ports matched and polished. Also, at their suggestion, the boost-port hole in the rear of the piston was opened up 1.5mm each way, except upward, in which direction the position of the lower ring only allowed us a 0.75mm enlargement. These modifications did not alter the machine’s perfect powerband, they just made it stronger through the mid-range and on top end. So much for the engine, at least for now.

The kit that Can-Am sent us to increase travel at the rear wheel was evaluated in the May issue also and was found to be an easy way to increase both handling and tractability without going the cost of welding. Rear-axle movement was measured at 5.5 in. That’s sufficient for most people, but some of us are difficult to satisfy, particularly after we’ve had a taste of the kind of suspension currently available on G.P. Huskys and Maicos. So we tried a cantilever arrangement. The welding was done by Greg Hartwell at P&G Engineering. It was a shame to let work as fine as Greg’s go to waste, but even with Torsten Hallman Bilsteins, the back end did not behave properly. Some bikes work well cantilevered, while others require a forward-mount. The Can-Am would need the latter, or so we thought.

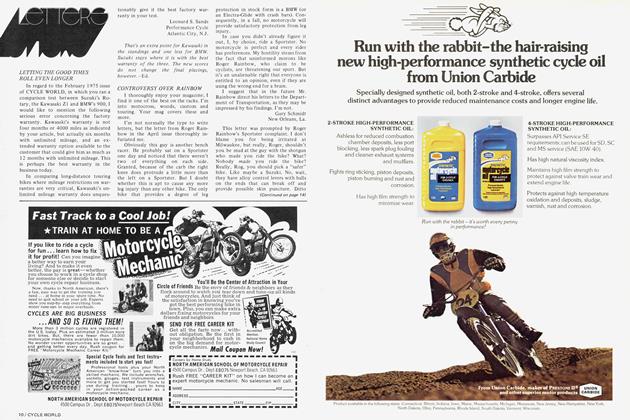

Back to Greg’s shop we went. Since the original modification had required the repositioning of the frame members, which run from behind the footpegs to the original upper shock mounts, by now positioning the top shock mount at the upper junction of the repositioned frame members, we could complete the first step of our new modification. But then we noticed that obtaining at least seven inches of rear-axle travel with a forward-mount would require an extremely short shock. It is virtually impossible for shocks shorter than 11 inches to have more than three inches of travel. This would have made the axleto-shock ratio greater than 2:1. The lower you can keep such a ratio, the less strain is placed on the shock and the longer it will last. So we left the lower shock mount where it was and went the other way, to a longer shock. Fourteenand-a-half-inch Curnutt gas/oil shocks >

were ordered. These have 4.7 in. of travel. Rear axle travel was 7.5 in., giving us an axle-to-shock travel ratio of 1.59:1. Much better than before.

With the Bilsteins in place, the axle travels only 6.6 in., making the A/S TR 1.65:1. Given our choice, we took the Curnutts, the extra inch of travel and the lower ratio. The Bilsteins are a more precise shock, but the Curnutts are more forgiving. Had the axle travel been the same, it would have been a tossup.

But now we were facing a different problem: more travel at the rear than up front. The Betor forks on the Can-Am offer only 6.75 in. of movement. Where does one go when such problems arise? Why, to a fork expert, of course. Brian Fabre at Number One Products took the forks from our bike, ran them on his shock dyno, and modified them slightly by boring the compression damping holes at the bottom of the damper rods out to 0.20 in. to achieve a more ideal damping curve. Then, he took a pair of Number One Products CZ fork extenders—which happen to have the same metric thread as the Betors—and, by reducing the outside diameter from 0.675 to 0.60, was able to attach them to the bottom of the Betor damper rods. Voila, 7.75 in. of travel! A little 20-wt. Bel-Ray in the fork legs and all suspension problems were solved.

Weight was one consideration when we began this modification, but up until now we hadn’t given it much extra thought. Most of the Can-Am’s excessive weight is unsprung. The wheels are heavy for a machine this size. D.I.D. rims were obtained from North American Imports, the U.S. distributor, and were laced to lightweight hubs from Can-Am’s new MX-2 line. People talk a lot about changes in unsprung weight, but until you experience the difference yourself, you may find it hard to believe the change. It impressed us so much that we went ahead and had the lower fork legs turned down. The difference here was minute, but noticeable.

Most of the major modifications were now complete. Only the lights, fenders and larger gas tank to go. The Can-Am’s 2.5-gal. tank is bigger than is normal for a 175cc dual-purpose machine, but then the Can-Am is not your average 175. Performance costs. In this case it costs in terms of fuel. . .more so now that the engine had been slightly modified. With the standard tank the bike could be raced for a maximum of 65 miles. Okay for trailing, but not enough for those long endurance G.P. events in which one less pit stop can mean the difference between having or not having a trophy-denoting asterisk after your name on the result sheet.

The gas tank situation put us face to face •with yet another problem. The Can-Am's backbone, which also serves as the injection system's reservoir, makes it difficult to fit most accessory tanks onto the frame. Of the skinny/fat style that we prefer, only the Vesco tank will fit. But it does not have a central uni-mount. So it was necessary to strap the tank to the frame by using rubber tank straps from the new G.P. Huskys fore and aft.

For fenders we went to Preston Petty. Since the machine would see some enduro action, one of the new Integral Taillight (I.T.) rear fenders, along with an Integral Bracket (I.B.) Mudder for the front, was installed. The headlight is also Preston's. Wiring the new lighting system, sans battery, was done by Mike Christenson at Precision Motorcycle Services. At first the juice provided by the lighting coils in the engine was a little too potent for the lights to take, but after hooking a Zener diode into the system, all went well.

The bike now has one minor fault. It sits, courtesy of the long-travel suspen sion at both ends, a little too tall for short riders. Fortunately, our staff con sists mainly of six-footers, so the prob lem is not serious for us.

Also, we removed the standard throt tle cable and replaced it with one that goes straight to the carburetor. Then we moved the spring and wired the oilinjection pump wide open. The pump on the Can-Am runs wide open after one-third throttle anyway, so for racing it works out perfectly. It makes replac ing broken cables a bunch easier too.

The bike is, for the moment, fin ished. But as soon as the new MX-2 175 is available, we're going to try its cylin der and rotary valve on our bike. We'll maintain the heavier flywheel ignition from the enduro, as well as the more

restrictive high pipe. Can-Am has al ready tried this combination on proto types and is getting frighteningly close to 28 horsepower with it. As is, the machine has been raced in the California City G.P., in which it was running 19th overall against all displacements until a fourth-gear plunge into an 8x8-ft. gully temporarily slowed it down. Still, our staffer/pilot trophied.

Of course, more races and enduros are scheduled for the Can-Am. No doubt high placings will be even easier to attain than before.

SUPPLIERS Jones Motocross Products 20868 Currier Rd. Walnut, CA 91789 (714) 595-9100 North American Imports 2325 Cerro Gordo P.O. Box N Mojave, CA 93501 (805) 824-4261 P&G Engineering 1958-C Placentia Costa Mesa, CA 92627 (714) 646-3271 Precision Motorcycle Services 1958-B Placentia Costa Mesa, CA 92627 (714) 548-8517 Number One Products 11509 Bexley Dr. Whittier, CA 90606 (213) 695-4119 Bombardier Ltd. Can-Am Motorcycle Division Valcourt, Quebec Canada Preston Petty Products Available through any motorcycle dealer Charles Curnutt 75992 Baseline 29 Palms, CA 92277 (714) 367-9179