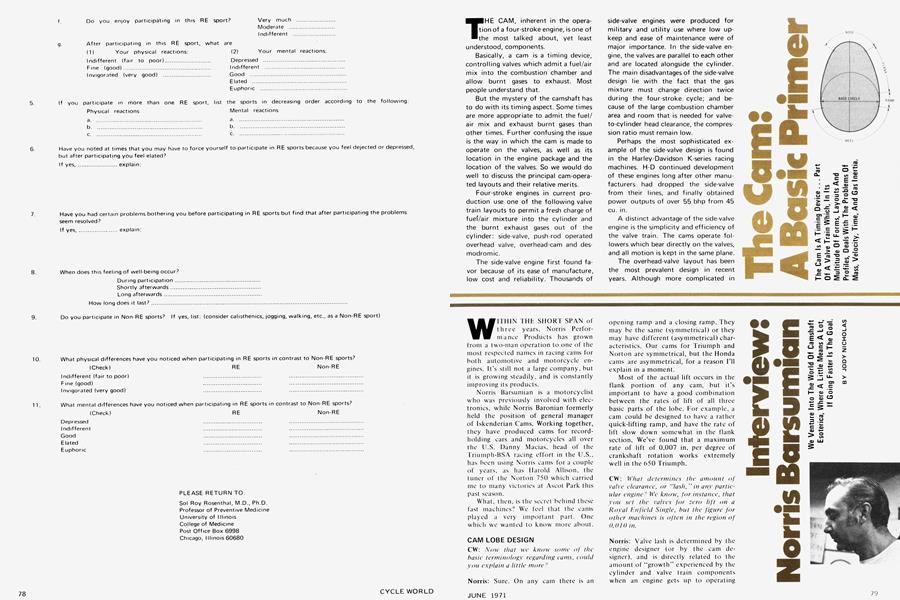

The Cam: A Basic Primer

The Cam Is A Timing Device...Part Of A Valve Train Which, In Its Multitude Of Forms, Layouts And Profiles, Deals With The Problems Of Mass, Velocity, Time, And Gas Inertia.

THE CAM, inherent in the operation of a four-stroke engine, is one of the most talked about, yet least understood, components.

Basically, a cam is a timing device, controlling valves which admit a fuel/air mix into the combustion chamber and allow burnt gases to exhaust. Most people understand that.

But the mystery of the camshaft has to do with its timing aspect. Some times are more appropriate to admit the fuel/ air mix and exhaust burnt gases than other times. Further confusing the issue is the way in which the cam is made to operate on the valves, as well as its location in the engine package and the location of the valves. So we would do well to discuss the principal cam-operated layouts and their relative merits.

Four-stroke engines in current production use one of the following valve train layouts to permit a fresh charge of fuei/air mixture into the cylinder and the burnt exhaust gases out of the cylinder: side-valve, push-rod operated overhead valve, overhead-cam and desmodromic.

The side-valve engine first found favor because of its ease of manufacture, low cost and reliability. Thousands of

side-valve engines were produced for military and utility use where low upkeep and ease of maintenance were of major importance. In the side-valve engine, the valves are parallel to each other and are located alongside the cylinder. The main disadvantages of the side-valve design lie with the fact that the gas mixture must change direction twice during the four-stroke cycle; and because of the large combustion chamber area and room that is needed for valveto-cylinder head clearance, the compression ratio must remain low.

Perhaps the most sophisticated example of the side-valve design is found in the Harley-Davidson K-series racing machines. H-D continued development of these engines long after other manufacturers had dropped the side-valve from their lines, and finally obtained power outputs of over 55 bhp from 45 cu. in.

A distinct advantage of the side-valve engine is the simplicity and efficiency of the valve train. The cams operate followers which bear directly on the valves, and all motion is kept in the same plane.

The overhead-valve layout has been the most prevalent design in recent years. Although more complicated in design and manufacture than the sidevalve engine, the greater efficiency and power output from the overhead-valve engine has greatly outweighed the complexity and production costs. Overhead-valve engines are able to use higher compression ratios, and the valve locations possible with such a design lead to much more power and less fuel consumption. Other advantages of the overhead-valve design include a better spark plug location within the combustion chamber, a more direct gas flow and better valve cooling.

Disadvantages of the overhead-valve design are mainly concerned with the valve gear. For example, in an engine such as the Triumph Trident, the cams' oscillatory motion is changed to straight-line motion through a tappet, which rides on a pushrod, which in turn bears on a rocker arm. The rocker arm reverses the straight-line motion and its end controls the opening and closing of the valve. Continuing development and better metals have allowed the overhead-valve engine to turn over at high speeds and develop high power outputs.

The overhead-cam engine currently is the most popular in America in terms of sheer number. Honda popularized the overhead-cam engine for general use some years ago, and such manufacturers as Ducati and, recently, Yamaha, add their sales to the growing number.

The overhead-cam engine combines all the advantages of the overhead-valve engine and is generally more efficient mechanically because the lifters, pushrods and, in some cases, the rocker arms are done away with entirely, thus saving reciprocating weight and thereby permitting the engine to turn at higher rpm. The main drawback of an overhead-cam engine is the drive mechanism for the cam itself. Gear trains are costly to manufacture and noisy in operation, as are bevel drives from the crankshaft. The most popular method of driving the cam is by chain, which is inexpensive to manufacture, gives virtually silent running and is easy to maintain. Honda's entire line, Yamaha's 650 and BSA/Triumph's dohc 350 employ chain-driven camshafts.

A fourth type of valve system currently in production is the desmodromic one which uses one cam to open each valve and another to close it. Theoretically, the desmodromic valve mechanism should be the most efficient in terms of valve control, but they are quite complicated and expensive to manufacture and generally noisy in operation. Ducati is the only motorcycle in general production today which offers a desmodromic valve system.

The most important single factor governing an engine's performance is the valve timing. Slight variations will cause the engine to produce good power at high revolutions, or have less total output but more power in the lower rpm ranges. It would seem that any engine having the breathing ability to produce power at high rpm should also have power at the other end of the rpm scale, but such is not often the case.

Because of the nature of air, which has weight, the engine designer runs into difficulties. Like anything that has weight, air has to be set into motion. If air were weightless, there would be no problems. The intake valve could be opened at top dead center, as the weightless air (fuel/air mixture) would begin moving into the cylinder at once. The intake valve could then be closed at bottom dead center because the air would cease to move.

On the other hand, if air were weightless, the exhaust valve could be opened at bottom dead center after the power stroke and all the burnt gases would rush out the cylinder and would stop when the piston again reached top dead center.

However, because moving air has inertia, it goes into motion slowly at first and gains speed as the piston draws it into the cylinder. When the piston is at bottom dead center, air is still trying to get in, and if the inlet valve were closed at bottom dead center, there would still be air trying to get in. The same is true of the exhaust. The burnt gases would not begin moving out of the cylinder immediately because of the low inertia of the charge, and some would still be trying to get out as the valve dropped closed at top dead center. As we can see, it takes time to get air in motion, and once in motion it has a tendency to stay in motion until it is acted upon by another force.

Knowing the physical properties of air (and air combined with fuel), the cam designer can use the inertia to advantage. As the incoming air rushes into the cylinder when the inlet valve is opened, its inertia has a tendency to keep it coming even after the piston has reached bottom dead center and has come back up on the compression stroke. The same thing happens with the exhaust, only in reverse. The inertia of the outgoing exhaust gases continues to make the pressures within the cylinder fall, and in some cases actually creates a negative pressure.

By taking advantage of this phenomenon, the cam designer can open the inlet valve even before the piston has come to top dead center, and with the exhaust valve open, the outgoing gases start the incoming charge moving, pulling it into the cylinder. You might think that the exhaust gases would blow the incoming charge back out the carburetor, and on some very long duration cams this happens at low engine speeds. Once the engine speed has been increased to within the operating parameters of the cam, a slight supercharging effect takes place.

Cam design, then, is the most important factor governing an engine's power characteristics. If an engine is designed to operate at low speeds, the duration (number of degrees of crankshaft rotation the valve is held open) may be quite short. As engine speed goes up though, the physical properties of air make it necessary to hold the valves ooen for longer periods of time to

fully pack the cylinder with all the air it can possibly get. Durations of over 300 degrees are commonly found on racing cams. Overlap, the period at the end of the exhaust and at the beginning of intake, when both valves are held open at the same time, is also directly related to the engine's intended use. A low rpm engine will have a cam with less overlap than one which must turn at high rpm.

Other considerations the cam designer has to take into account are the various components in the valve train. The cam must have something to push on to eventually open the valve and allow it to close. These devices are called cam followers or tappets, and may be of the flat, radiused or roller variety. All have their advantages and limitations, and all are constructed from the finest steel, usually with a high nickel content, and are heat-treated to reduce wear.

Flat or radiused tappets can be made very light, and with today's high quality steels and excellent lubricants, wear is usually not a serious problem. Roller tappets are somewhat heavier than either the flat or radiused tappet, and have a tendency to "skid" in some applications as the cam begins taking up its lift. The roller is at its best when large-diameter components can be used with heavy valve train components and springs.

The pushrod in an overhead-valve engine must be made as light as possible to eliminate bending or flexing, thus permitting high rpm while accurately controlling the valve's opening and closing. A long, weak pushrod has a tendency to flex or "whip" at high rpm, causing valve timing to vary radically. With an overhead cam engine, of course, there is no pushrod.

Rocker arm design has remained fairly constant over the past few years, with the "l-section" approach "being the most popular. It is relatively easy to manufacture and is very strong. Rocker arms are quite often longer from the fulcrum (pivot point) to the valve end than from the fulcrum to the pushrod end. This difference in length determines the rocker arm ratio and is used to open the valve to a greater extent than the lift of the cam. This is an advantage in that the physical size of the cam cavity can be smaller, reducing in some instances the size of the crankcase casting.

But all this valve gear, and the valve itself, has the same disadvantage that air has: it has inertia which must be overcome.

Obviously, the valve cannot be opened or closed slapdash because of possible damage to it and other of the valve train components. The valve must be eased open and then eased closed, but in the most rapid manner possible. Therefore, the cam designer has another headache which he must overcome to get the best performance out of an engine with maximum reliability. On a high-performance engine he must accelerate the valve open to its maximum lift as quickly as possible, hold it open as long as possible and then have it close again.

In all valve systems except the desmodromic, closing the valve is the responsibility of the valve spring, which must also return the rocker arm (and in the case of the overhead-valve engine, the pushrod and lifter) to its original position before the valve can close. Hairpin valve springs were brought into use during the 1930's because they could be made stronger than the coil spring, but today the coil spring reigns supreme and is in almost universal use. The most notable exceptions are the Ducati, which uses hairpin springs, and the dohc Honda 450, which uses torsion bars to close the valves. All of these types are good if they are able to control the valve's movements accurately at any speed in the engine's operating range.

(Continued on page 114)

Continued from page 83

The problems with an incorrectly designed or weak spring are numerous. As the cam begins accelerating the valve toward its maximum open position, the spring's job is relatively easy, as most of the acceleration occurs up the cam's flank. As the lifter nears the nose, however, the acceleration rate slows markedly before the lifter begins its downward travel. If the spring isn't doing its job properly, the valve and valve train mass will continue accelerating at such a rate that it will hardly touch the nose portion of the cam, and may even be in the air after the cam has moved past its point of maximum lift. The valve mechanism then picks up speed and will come crashing down, late, and with such force that the valve may actually bounce off the seat a number of times.