THE PNEUMATIC TIRE

Complex, Indispensable, Always Taken For Granted.

WILLIAM HAMPTON

THE NEXT TIME you get ready to ride your twowheeler, take a moment and look at its tires. If it weren't for those two hoops of rubber, motorcycles might have never evolved.

So that you may better appreciate this versatility of the pneumatic tire and its influence on your bike's handling, let's take an in-depth look at this rubberized component to see how it performs, how it's designed and constructed, and how it can be kept functioning more efficiently with just a simple act of maintenance.

RUBBER: AN IDEAL MATERIAL

First, let's see why rubber is such an ideal material for tires. To appreciate the efficacy of this material, all you'd have to do, if it were possible, would be to ride your bike on its wheel rims. The ride would be harsh and noisy. Panic braking from 60 or 70 miles per hour, or cornering on wet pavement, would be impossible.

Happily, with rubber we don't have these problems, simply because it has the capacity to distort under load, at ground level. This provides the necessary stability and traction. In fact, the degree of traction maintained is proportional to the amount of distortion occurring.

If it weren't for this capacity to twist itself out of shape, the tire would be very unstable, due to its fixed limit of adhesion. There would be no warning of approaching this limit, either. In other words, the rider would have to crash to find out the limit of adhesion for his particular machine.

But since the tire does distort in a turn, riders don't have to worry about spilling, should they enter a turn somewhat too vigorously. This is true because of a condition known as "slip angle." It's the difference between the direction in which the wheel is pointing and the patch that the tire is actually traveling.

Here's how it works: when a bike is banked over, the side load imposed on that portion of the tire in contact with the road "pushes" the tire over, so that the tread coming down ends up touching the road off to the outside of the pre-existent contact area.

This slip angle is an understeering effect that makes a bike travel in a wider arc than was intended. In a sense, it's a built-in margin for error, since the slip angle will correct for an excessive angle of lean. But, if a bike is banked over too far, even the slip angle won't keep it up.

Another beneficial action of the tire is its self-alignment behavior, which keeps the wheel running in a straight-ahead direction. For instance, if the wheel is turned slightly to the side, the tire distorts at its contact patch and twists itself back into line, until it's tracking straight again. If it were not for this innate stabilizing action, constant corrections for wheel deflections would be necessary. To say that this would be annoying is putting it mildly.

In addition to the slip angle and self-alignment factors, pneumatic tires provide yet another advantage, that of camber thrust. This occurs whenever the tire is banked in relation to the road, or vice-versa. What happens is that a side thrust pushes against the tire's contact patch in the direction of bank in an effort to restore the wheel to a vertical position. When the tire strikes a bump in the road, camber thrust is responsible for restoring stability by pulling the tire up the side of the bump, to counter the deflective force.

As important as these advantages of slip angle, self-alignment, and camber thrust are, however, the tire must still maintain adequate contact with the road. Therefore, it must have the proper tread pattern. But, what kinds of tread patterns provide the best traction? Actually, it all depends on the surface conditions that the tire is designed for. It's safe to assume that for road riding, there must be more tread on the ground than would be necessary on a loose-dirt surface, which would require a knobbier design.

ANY TREAD PATTERN WON'T DO

Actually, under ideal paved-road conditions, a smooth tire would provide better traction than a treaded one. This is true because on a smooth, clean, dry surface, a treadless tire would have more contact area. Obviously, such conditions don't exist, since paved roads usually have surface irregularities to begin with, along with an abundance of dirt, oil drippings and tire-wear particles from other vehicles. When rain is added to all this, you can readily see the folly of riding a bike with bald tires. But, just any tread pattern won't ensure optimal traction. Also, there is the different performance characteristics of both the front and rear tires to contend with.

Take the front tire for instance. It must grip the road at varying bank angles and still transmit braking force to the road surface. And the front tire must allow responsive steering.

Besides maintaining traction at different bank angles and transmitting braking forces to the road, the rear tire has the added task of delivering the engine's power pulses to the road without incurring a serious loss of traction. To do this, the rear tire must have its tread-blocks at right angles to the direction of wheel thrust. Braking forces are also utilized better by the edges of blocks situated in this transverse, or crossways, manner.

Cornering is something else. Here traction depends on the edges of the tread running parallel to the tire's direction of travel. And, as braking is often done during the act of cornering, there must be a suitable tread pattern around the lower sides of the tire to cope with braking forces.

Besides the shape and location of the tread blocks, there are other means for improving traction. Look at a block-tread pattern used for road riding. You'll notice channels, or grooves, going every which way between the blocks. When the pressure edges of these blocks shear through road film, these channels have the job of carrying away the road dirt from underneath the tire. The manner in which the channels are arranged depends on the block form of the tread.

Channel arrangement is particularly important in wet weather. Together with the squeegee effect of the tread-block edges, channels provide a way for water to escape from underneath the tire. Without this squeegee effect and water dispersal, the tire would hydroplane, or skim over the road on a film of water. The smoother the tread, the easier it is for a tire to hydroplane, since the water can't escape properly. But even with a new tire, this phenomenon is possible, if the bike's speed is great enough and/or if there is an abundance of water on the road.

Channels have another purpose, too. They make the tread flexible, allowing it to adhere to the road and conform to surface irregularities. Contributing to this flexibility are the sipes, or "knife cuts," that are made in the tread. They are just another means for making the tire grip well on wet and dry roads.

But, as desirable as tread flexibility is, too much will make a tire unstable. This lack of stability would be especially > noticeable in a turn, because the tire would tend to crawl off to the side. Tire designers overcome this excessive-flexure problem by incorporating little connective bars between the blocks to limit their movement.

Aside from the problem of too much flexibility, tread blocks present another problem: noise. As the tire rotates, those tread blocks slap against the road. As speed increases, the noise increases. But, by varying the shape and spacing of the tread blocks, tire designers are able to control the noise factor. If they weren't able to, the resonance set up by all those blocks of rubber striking the road at speed would compel you to wear ear plugs.

Incidentally, those tread blocks help dissipate heat generated by the tire as it pounds against the road. The side areas of the blocks are, in effect, cooling fins, much like those on the engine. And all those channels help direct air flow around the blocks.

RIBBED VS. TRIALS VS. KNOBBY

Before we look inside a tire to see how it's constructed, let's see what tread patterns are used on today's tires.

For road riding, there are two basic designs. One, the closely spaced, block tread pattern, is called a universal design. It can be used on either the front or rear wheel. This universal design is a highly efficient tire that provides good traction on firm dirt surfaces as well as on paved roads. When it's used on the front, however, it sometimes has a tendency to "cup" or wear unevenly. Nonetheless, it does grip well and steers lightly.

The other design is the ribbed tread. Strictly a front wheel tire, it's noted for its low-rolling resistance, light steering, and slow wear qualities. Its circumferential ribs permit sharp cornering, while minimizing sideslip. In wet weather, the ribs channel and disperse water, so maximum traction is maintained. This design is ineffective for rear wheel use as its lack of tread blocking prevents adequate power transmission to the road.

For off-road use, there is the true sports tire, or "knobby" design, which features large square and/or circular knobs of different sizes and spacing.

A typical off-road knobby tire will have some 200 wide-based tread blocks, angled to allow them to bite into any terrain. These blocks are wide at the base to ensure stability, extra reinforcement, and torque resistance. And, as any good off-road tire must be, knobby tires are self-cleaning. This quality of self-cleaning is a must. If the spaces between the blocks fill up with mud, dirt, or stones, traction is impaired.

Not only must the knobs be spaced properly to prevent their being clogged, but they must be high and thick enough to dig in. Yet, if they are too high or too thin, they can be torn off.

Between these two extremes of road tire and the off-road tire, we have a compromise tread design called the trials-universal. It's for the enthusiast who is willing to forego the specialized efficiency of either a true sports tire or a road tire, so that he can ride both on and off the road. Although the tread blocks on this tire are closer together than those on a sports knobby, they still don't provide the optimum contact area of a road tire for serious paved-road riding. If you ride moderately fast on the street and play around in the dirt too, the trials-universal is the one to use.

On a wet road, however, this design requires caution. Not so in the rough stuff, though, for it is stable laterally and tractive in sand and mud. When it's used on the front, it becomes ideal for climbing out of ruts. The trials-universal is often used in this way, with a sports knobby on the back. Typical trials universals have V-shaped blocks, that can dig in for good traction in the loose stuff. When cornering on pavement, the V-blocks resist sideslipping in the same way the ribs on a ribbed tread do.

Speaking of tread design brings us to a comment or two about racing tires. Their tread patterns are basically the same as those for touring tires. But some racing tires that are used strictly on paved courses have a triangular cross-section, which allows them to put more tire in contact with the road when cornering. When running upright, they have little rolling resistance.

NATURAL OR SYNTHETIC?

As we delve more deeply into tire behavior, we realize there is far more to developing a tractive pneumatic tire than just putting a tread pattern on it. And how well a particular tread design does its job depends on the tire's construction.

Choice of rubber is very important. As many as five or six different compounds can be used in the same tire. The tread requires a special compound, and underneath that another kind of compound is used to back up, or cushion, the tread. For bracing the bead, a hard rubber is used. And yet another very tacky compound is used to adhere to the cord fibers and to bond with the other layers of rubber.

The composition of these compounds consists of such ingredients as natural rubber, butyl (snythetic rubber), carbonblack, and oil. Also, chemicals are added to reduce the static build-up that a rolling tire incurs, and to prevent ozone attack and consequent deterioration of the tire.

For obvious reasons, the tread compound on motorcycle tires is "stickier," or more adhesive, than that used on automotive tires. The motorcycle's single-track nature doesn't allow a wide margin of error when it comes to critical traction situations. That's why a comparatively soft rubber is used on the bike's tread pattern. Actually, the coefficient of friction doesn't vary much between a hard rubber or a soft rubber. If roads had glass-smooth surfaces, a hard-rubber tread would be just as tractive as a smooth-rubber tread. But, road surfaces are textured and full of irregularities, and it takes a soft rubber to press into and conform to these irregularities.

Despite the higher tractive qualities of a soft rubber, it's still subject to local vibrations at the contact patch. Depending on surface roughness and wheel speed, these vibrations do keep the tire from maintaining ideal traction.

A special compound rubber was discovered to permit the tire to adhere to the road by absorbing vibrations. Termed high-hysteresis rubber, or, more colloquially, "cling" rubber, it proved superior to conventional compounds. So much so, in fact, that traction on a wet road improved by as much as 25 percent. Even on dry surfaces, one can corner more sharply with this rubber. And the beauty of it all is that this compound wears better than conventional rubber, under normal touring conditions.

To appreciate this cling rubber more, you must understand how it works. When cling rubber impacts against a hard surface, it absorbs most of the impact energy and converts it into heat. The degree of heat build-up occurs both from the tire flexing and from pounding against the road. Under normal conditions, this generation of heat is inconsequential. But, at road-racing speeds, the tire's internal friction can create enough heat to lower absolute top speed slightly. However, the tractive qualities of the cling-rubber racing tire at low speeds more than offsets the slight loss of top end speed.

While cling rubber is used to great advantage in street and road-racing tires, natural rubber is more suitable for sportsknobby tires. It's natural rubber's resistance to tearing that makes it so effective for a knobby tread. The torque of a powerful off-road bike places a tremendous strain on all those tread knobs. Even though knobby tires have a greater amount of natural rubber, they still use some synthetic compounds.

CORD ANGLE AND CORNERING

Regardless of whether it's an off-road tire or a road tire, how well it performs will be determined by its casing or carcass structure. And the manner in which the cords in the casing are arranged determines, in turn, how the casing will yield or remain firm, under both circumferential and radial loading.

If the only problem were to keep the tire from blowing out, the cords could be arranged at 90-deg. angles to the bead. But then, the tire would deform abnormally, as when cornering. When banked for a turn, side thrust would distort the tire and shift its contact patch, thus making the tire track at an excessive slip angle. Tire deformation would be checked only by the stiffness of the rubber itself.

Now, looking at the other extreme, if the cords were set 0 deg., or parallel to the bead, the tire would be so strongly braced, it would hardly deform laterally when under load. The only way it could do so would be to pull cord from around its circumference.

Between these two extremes of 0 deg. and 90 deg., tire designers choose cord angles that make tires both rigid and yielding under varying load conditions. Goodyear's engineers, for example, have found that the best all-around results are obtained for a touring tire when the cord angles are placed between 38 and 40 deg. Within this range, the tire has enough flexibility without there being an undesirable "softness" that would affect handling. Higher angles do soften the riding qualities, but tt>ey don't permit the tire to corner well.

Despite all these advancements in tread patterns, rubber compounds, and tire construction, there is always something new being discovered. One such discovery has been the use of tubeless tires for racing motorcycles. Whether such tires will ever become practical for mass-production motorcycles remains to be seen, but tubeless tires were used successfully on Roger Reiman's Harley-Davidson road racer at Daytona International Speedway.

Reiman conceived the idea of a tubeless tire, then worked closely with Goodyear engineers to effect a means for sealing the spoke holes in his bike's rims. By dispensing with the tubes, they eliminated 8 lb. of unsprung weight. Another advantage gained was reduction in centrifugal force caused by the spinning wheels.

MAINTENANCE TIPS

All the various aspects of tire maintenance couldn't be covered here, but the more important can be, and one is keeping your tires inflated properly. It's surprising how many of us neglect this particular function. Either we are forgetful or downright lazy, but the fact remains that many of us just don't bother about checking tire pressures as often as we should.

Because air can seep through a porous tube or past a leaky valve, underinflation is usually more of a problem than overinflation. But, how much difference does a few pounds of less-than-normal air pressure make anyway? Quite a difference!

Consider this fact for a moment: a tire that runs at 80 percent of its normal pressure can lose as much as 20 percent of its life. When a tire is underinflated, there is more of it in contact with the road. As a result, more friction is generated than would normally occur with a properly inflated tire having a smaller contact surface. Also, a soft tire flexes more, thereby generating more heat. This, together with the heat produced by the bigger contact patch, helps to bring about a rapid deterioration of the tire. Over a period of time, cracks develop on the sidewalls which can tear.

Besides the sidewalls tearing, the tread can separate from the carcass. Other damage can occur inside the tire, such as the plies separating from each other, and the fabric breaking down from stress. When a tire suffers internal damage, it can chafe the tube and eventually deflate it. Tires can be prevented from incurring such damage by topping them up before they get too low.

Slightly underinflated tires will also damage tubes. For instance, on the back wheel, accelerating and braking on a soft tire can permit it to creep on the rim and tear away the valve. The same goes for the front wheel if hard braking is indulged in.

There is also the possibility of denting a rim when running over pot holes or into curbs.

Besides creating a lot of heat and inflicting damage to the tire and tube, underinflation causes rapid wear of the side tread. If enough of this tread wears away, chances for skidding in a turn are enhanced.

Underinflated tires make for sloppy handling, too, because the tire is acting as a roller between the wheel and the road. Since the bike can't track properly, it tends to wander, especially in a turn.

No doubt about it, underinflation can wreak irreparable harm; but, don't overlook the dangers of overinflation.

A board-hard tire can't maintain optimal traction. Even with a good suspension system, overinflated tires will bounce over the ground surface at the slightest provocation. And cornering can be a nightmare, because the reduced slip angle can't cope with steep bank angles. Without an adequate slip angle to compensate for a steep turn, your bike can drop you without any warning of the limit of tire adhesion.

The overinflated tire's smaller contact patch has to carry a heavier loading that accelerates wear of the tire's center area. Also, a smaller contact patch means a longer braking distance.

Like underinflation, overinflation can seriously damage a tire by inducing internal deterioration. The overstressing of the ply-fabric threads caused by shock from pot holes, rocks, etc., weakens the tire, which can lead to its complete failure. Overstressing can cause the tread to tear when it strikes a hard, sharp object, also.

With all the marvelous advantages your tires offer in the way of stability, comfort, and performance, they still need looking after. But they don't require much of your time. If you're a road rider, get into the habit of checking air pressure at least once a week. If you ride in any form of competition, any such advice is superfluous.

Who knows, maybe some day the pneumatic tire will be replaced by some more efficient material. But until that time, you're going to have to live with what is available. [Ö]

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

DECEMBER 1971 By Joe Parkhurst -

Letters

LettersLetters

DECEMBER 1971 -

Departments

DepartmentsThe Service Dept

DECEMBER 1971 By Jody Nicholas -

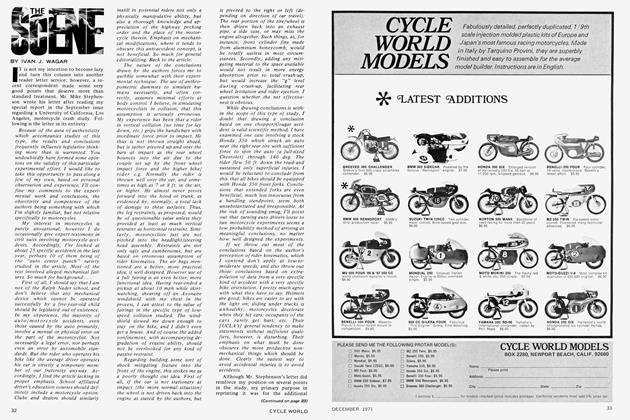

Departments

DepartmentsThe Scene

DECEMBER 1971 By Ivan J. Wagar -

Features

FeaturesViewpoint: the Road Bike In Tomorrow's World

DECEMBER 1971 By Dan Hunt -

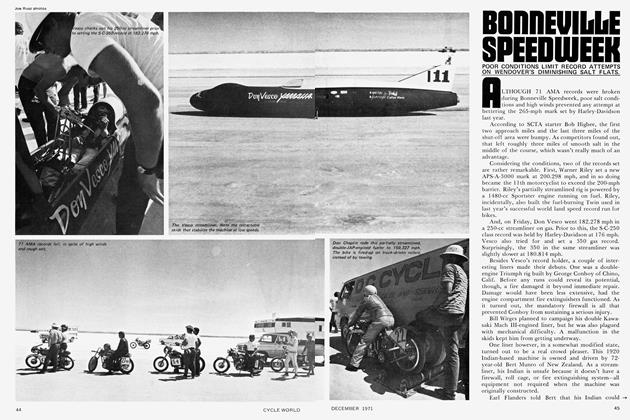

Competition

CompetitionBonneville Speedweek

DECEMBER 1971