Battery Care

WILLIAM HAMPTON

THE OLD ADAGE, "Out of sight, out of mind", is especially applicable to the battery and its maintenance. Aside from an occasional topping-up, many, if not the majority of riders neglect this vital component. When battery failure does occur, they blame that little electro-chemical storehouse instead of themselves.

Considering the amount of abuse and neglect the motorcycle battery is subjected to, it's amazing it endures as long as it does. The basic lead-acid battery iscomprised of two lead plates immersed in an electro lytic solution of sulfuric acid and water. When current is passed from one plate to another, it causes the first plate (positive) to form a surface of dark brown peroxide of lead. The second, or negative plate, re mains lead-gray in color. However, modern batteries are made up of lead grids instead of plates. The positive grid is covered with a lead peroxide paste, while the negative one is filled with a special spongy lead paste. A battery's electrical capacity is de termined by size and number of plates. or grids. The larger they are, the more cur rent they will yield. But since motorcycle batteries have to be quite small, the grids and plates can't be large. Therefore, to get a large plate-grid area into a small space, the grids or plates are sandwiched into the battery case and separated by thin, plastic spacers. The plates or grids are connected at the top by positive and negative bridge pieces to which the respective positive and negative terminals are attached. Because grids are more commonly employed in modern motorcycle batteries, they will be discussed, instead of plates, throughout the remainder of the article. -

Whether the battery is overcharged or discharged, the same chemical reaction takes place within it. Through the process of electrolysis, water is split into its com ponent forms of hydrogen and oxygen. During discharge, the oxygen forms a lead oxide. This combines chemically with the acid to form lead sulfate. This is what happens when the battery is said to be sulfated.

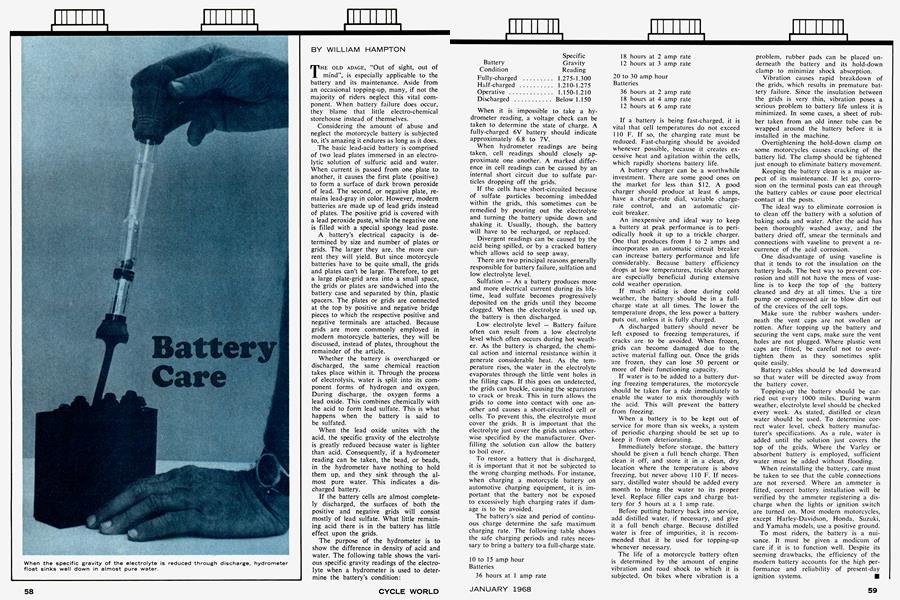

When the lead oxide unites with the acid, the specific gravity of the electrolyte is greatly reduced because water is lighter than acid. Consequently, if a hydrometer reading can be taken, the bead, or beads, in the hydrometer have nothing to hold them up, and they sink through the al most pure water. This indicates a dis charged battery.

If the battery cells are almost complete ly discharged, the surfaces of both the positive and negative grids will consist mostly of lead sulfate. What little remain ing acid there is in the battery has little effect upon the grids.

The purpose of the hydrometer is to show the difference in density of acid and water. The following table shows the vari ous specific gravity readings of the electro lyte when a hydrometer is used to deter mine the battery's condition:

When it is impossible to take a hydrometer reading, a voltage check can be taken to determine the state of charge. A fully-charged 6V battery should indicate approximately 6.8 to 7V.

When hydrometer readings are being taken, cell readings should closely approximate one another. A marked difference in cell readings can be caused by an internal short circuit due to sulfate particles dropping off the grids.

If the cells have short-circuited because of sulfate particles becoming imbedded within the grids, this sometimes can be remedied by pouring out the electrolyte and turning the battery upside down and shaking it. Usually, though, the battery will have to be recharged, or replaced.

Divergent readings can be caused by the acid being spilled, or by a cracked battery which allows acid to seep away.

There are two principal reasons generally responsible for battery failure, sulfation and low electrolyte level.

Sulfation — As a battery produces more and more electrical current during its lifetime, lead sulfate becomes progressively deposited on the grids until they become clogged. When the electrolyte is used up, the battery is then discharged.

Low electrolyte level — Battery failure often can result from a low electrolyte level which often occurs during hot weather. As the battery is charged, the chemical action and internal resistance within it generate considerable heat. As the temperature rises, the water in the electrolyte evaporates through the little vent holes in the filling caps. If this goes on undetected, the grids can buckle, causing the separators to crack or break. This in turn allows the grids to come into contact with one another and causes a short-circuited cell or cells. To prevent this, the electrolyte must cover the grids. It is important that the electrolyte just cover the grids unless otherwise specified by the manufacturer. Overfilling the solution can allow the battery to boil over.

To restore a battery that is discharged, it is important that it not be subjected to the wrong charging methods. For instance, when charging a motorcycle battery on automotive charging equipment, it is important that the battery not be exposed to excessively high charging rates if damage is to be avoided.

The battery’s size and period of continuous charge determine the safe maximum charging rate. The following table shows the safe charging periods and rates necessary to bring a battery toa full-charge state.

10 to 15 amp hour Batteries 36 hours at 1 amp rate If a battery is being fast-charged, it is vital that cell temperatures do not exceed 110 F. If so, the charging rate must be reduced. Fast-charging should be avoided whenever possible, because it creates excessive heat and agitation within the cells, which rapidly shortens battery life.

A battery charger can be a worthwhile investment. There are some good ones on the market for less than $12. A good charger should produce at least 6 amps, have a charge-rate dial, variable chargerate control, and an automatic circuit breaker.

An inexpensive and ideal way to keep a battery at peak performance is to periodically hook it up to a trickle charger. One that produces from 1 to 2 amps and incorporates an automatic circuit breaker can increase battery performance and life considerably. Because battery efficiency drops at low temperatures, trickle chargers are especially beneficial during extensive cold weather operation.

If much riding is done during cold weather, the battery should be in a fullcharge state at all times. The lower the temperature drops, the less power a battery puts out, unless it is fully charged.

A discharged battery should never be left exposed to freezing temperatures, if cracks are to be avoided. When frozen, grids can become damaged due to the active material falling out. Once the grids are frozen, they can lose 50 percent or more of their functioning capacity.

If water is to be added to a battery during freezing temperatures, the motorcycle should be taken for a ride immediately to enable the water to mix thoroughly with the acid. This will prevent the battery from freezing.

When a battery is to be kept out of service for more than six weeks, a system of periodic charging should be set up to keep it from deteriorating.

Immediately before storage, the battery should be given a full bench charge. Then clean it off, and store it in a clean, dry location where the temperature is above freezing, but never above 110 F. If necessary, distilled water should be added every month to bring the water to its proper level. Replace filler caps and charge battery for 5 hours at a 1 amp rate.

Before putting battery back into service, add distilled water, if necessary, and give it a full bench charge. Because distilled water is free of impurities, it is recommended that it be used for topping-up whenever necessary.

The life of a motorcycle battery often is determined by the amount of engine vibration and road shock to which it is subjected. On bikes where vibration is a

problem, rubber pads can be placed underneath the battery and its hold-down clamp to minimize shock absorption.

Vibration causes rapid breakdown of the grids, which results in premature battery failure. Since the insulation between the grids is very thin, vibration poses a serious problem to battery life unless it is minimized. In some cases, a sheet of rubber taken from an old inner tube can be wrapped around the battery before it is installed in the machine.

Overtightening the hold-down clamp on some motorcycles causes cracking of the battery lid. The clamp should be tightened just enough to eliminate battery movement.

Keeping the battery clean is a major aspect of its maintenance. If let go, corrosion on the terminal posts can eat through the battery cables or cause poor electrical contact at the posts.

The ideal way to eliminate corrosion is to clean off the battery with a solution of baking soda and water. After the acid has been thoroughly washed away, and the battery dried off, smear the terminals and connections with vaseline to prevent a recurrence of the acid corrosion.

One disadvantage of using vaseline is that it tends to rot the insulation on the battery leads. The best way to prevent corrosion and still not have the mess of vaseline is to keep the top of the battery cleaned and dry at all times. Use a tire pump or compressed air to blow dirt out of the crevices of the cell tops.

Make sure the rubber washers underneath the vent caps are not swollen or rotten. After topping up the battery and securing the vent caps, make sure the vent holes are not plugged. Where plastic vent caps are fitted, be careful not to overtighten them as they sometimes split quite easily.

Battery cables should be led downward so that water will be directed away from the battery cover.

Topping-up the battery should be carried out every 1000 miles. During warm weather, electrolyte level should be checked every week. As stated, distilled or clean water should be used. To determine correct water level, check battery manufacturer’s specifications. As a rule, water is added until the solution just covers the top of the grids. Where the Varley or absorbent battery is employed, sufficient water must be added without flooding.

When reinstalling the battery, care must be taken to see that the cable connections are not reversed. Where an ammeter is fitted, correct battery installation will be verified by the ammeter registering a discharge when the lights or ignition switch are turned on. Most modem motorcycles, except Harley-Davidson, Honda, Suzuki, and Yamaha models, use a positive ground.

To most riders, the battery is a nuisance. It must be given a modicum of care if it is to function well. Despite its seeming drawbacks, the efficiency of the modern battery accounts for the high performance and reliability of present-day ignition systems.