SPARKPLUG TOPICS

WILLIAM HAMPTON

THE SPARKPLUG is one of the most misunderstood and taken-for-granted components on a motorcycle.

Much of the misinformation concerning sparkplugs stems from their inherently simple construction and operation. The sparkplug has a basic function to perform: provide a proper spark in the cylinder when needed. Despite its simple construction and function, the sparkplug is subject to many complex factors, especially where high-performance motorcycle engines are concerned. This is why it is imperative for the motor cyclist who wants maximum performance and reliability to use only sparkplugs that are specified for motorcycle engines.

There are many types of sparkplugs available that cover the whole gamut of operational conditions that any rider is likely to encounter. For maximum results, one has to choose a plug for the particular running conditions under which his machine operates.

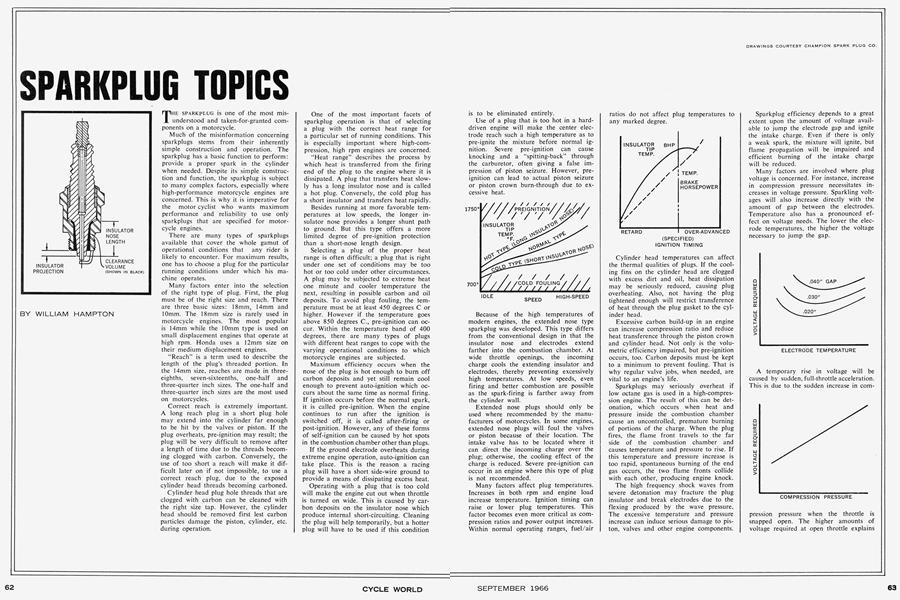

Many factors enter into the selection of the right type of plug. First, the plug must be of the right size and reach. There are three basic sizes: 18mm, 14mm and 10mm. The 18mm size is rarely used in motorcycle engines. The most popular is 14mm while the 10mm type is used on small displacement engines that operate at high rpm. Honda uses a 12mm size on their medium displacement engines.

"Reach" is a term used to describe the length of the plug's threaded portion. In the 14mm size, reaches are made in threeeighths, seven-sixteenths, one-half and three-quarter inch sizes. The one-half and three-quarter inch sizes are the most used on motorcycles.

Correct reach is extremely important. A long reach plug in a short plug hole may extend into the cylinder far enough to be hit by the valves or piston. If the plug overheats, pre-ignition may result; the plug will be very difficult to remove after a length of time due to the threads becoming clogged with carbon. Conversely, the use of too short a reach will make it difficult later on if not impossible, to use a correct reach plug, due to the exposed cylinder head threads becoming carboned.

Cylinder head plug hole threads that are clogged with carbon can be cleaned with the right size tap. However, the cylinder head should be removed first lest carbon particles damage the piston, cylinder, etc. during operation.

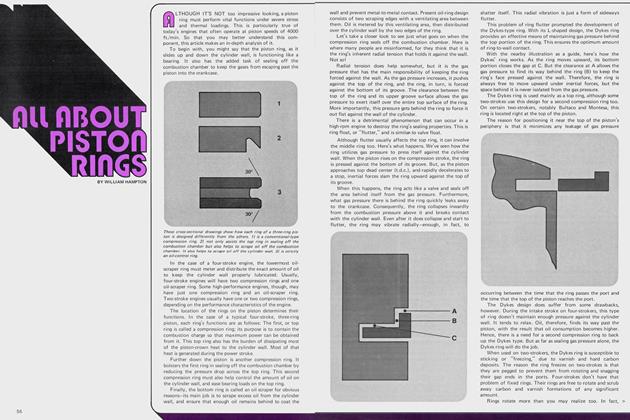

One of the most important facets of sparkplug operation is that of selecting a plug with the correct heat range for a particular set of running conditions. This is especially important where high-compression, high rpm engines are concerned.

"Heat range" describes the process by which heat is transferred from the firing end of the plug to the engine where it is dissipated. A plug that transfers heat slowly has a long insulator nose and is called a hot plug. Conversely, the cold plug has a short insulator and transfers heat rapidly.

Besides running at more favorable temperatures at low speeds, the longer insulator nose provides a longer shunt path to ground. But this type offers a more limited degree of pre-ignition protection than a short-nose length design.

Selecting a plug of the proper heat range is often difficult; a plug that is right under one set of conditions may be too hot or too cold under other circumstances. A plug may be subjected to extreme heat one minute and cooler temperature the next, resulting in possible carbon and oil deposits. To avoid plug fouling, the temperature must be at least 450 degrees C or higher. However if the temperature goes above 850 degrees C., pre-ignition can occur. Within the temperature band of 400 degrees, there are many types of plugs with different heat ranges to cope with the varying operational conditions to which motorcycle engines are subjected.

Maximum efficiency occurs when the nose of the plug is hot enough to burn off carbon deposits and yet still remain cool enough to prevent auto-ignition which occurs about the same time as normal firing. If ignition occurs before the normal spark, it is called pre-ignition. When the engine continues to run after the ignition is switched off, it is called after-firing or post-ignition. However, any of these forms of self-ignition can be caused by hot spots in the combustion chamber other than plugs.

If the ground electrode overheats during extreme engine operation, auto-ignition can take place. This is the reason a racing plug will have a short side-wire ground to provide a means of dissipating excess heat.

Operating with a plug that is too cold will make the engine cut out when throttle is turned on wide. This is caused by carbon deposits on the insulator nose which produce internal short-circuiting. Cleaning the plug will help temporarily, but a hotter plug will have to be used if this condition is to be eliminated entirely.

Use of a plug that is too hot in a harddriven engine will make the center electrode reach such a high temperature as to pre-ignite the mixture before normal ignition. Severe pre-ignition can cause knocking and a "spitting-back" through the carburetor, often giving a false impression of piston seizure. However, preignition can lead to actual piston seizure or piston crown burn-through due to excessive heat.

Because of the high temperatures of modern engines, the extended nose type sparkplug was developed. This type differs from the conventional design in that the insulator nose and electrodes extend farther into the combustion chamber. At wide throttle openings, the incoming charge cools the extending insulator and electrodes, thereby preventing excessively high temperatures. At low speeds, even firing and better combustion are possible as the spark-firing is farther away from the cylinder wall.

Extended nose plugs should only be used where recommended by the manufacturers of motorcycles. In some engines, extended nose plugs will foul the valves or piston because of their location. The intake valve has to be located where it can direct the incoming charge over the plug; otherwise, the cooling effect of the charge is reduced. Severe pre-ignition can occur in an engine where this type of plug is not recommended.

Many factors affect plug temperatures. Increases in both rpm and engine load increase temperature. Ignition timing can raise or lower plug temperatures. This factor becomes even more critical as compression ratios and power output increases. Within normal operating ranges, fuel/air ratios do not affect plug temperatures to any marked degree.

Cylinder head temperatures can affect the thermal qualities of plugs. If the cooling fins on the cylinder head are clogged with excess dirt and oil, heat dissipation may be seriously reduced, causing plug overheating. Also, not having the plug tightened enough will restrict transference of heat through the plug gasket to the cylinder head.

Excessive carbon build-up in an engine can increase compression ratio and reduce heat transference through the piston crown and cylinder head. Not only is the volumetric efficiency impaired, but pre-ignition occurs, too. Carbon deposits must be kept to a minimum to prevent fouling. That is why regular valve jobs, when needed, are vital to an engine's life.

Sparkplugs may seriously overheat if low octane gas is used in a high-compression engine. The result of this can be detonation, which occurs when heat and pressure inside the combustion chamber cause an uncontrolled, premature burning of portions of the charge. When the plug fires, the flame front travels to the far side of the combustion chamber and causes temperature and pressure to rise. If this temperature and pressure increase is too rapid, spontaneous burning of the end gas occurs, the two flame fronts collide with each other, producing engine knock.

The high frequency shock waves from severe detonation may fracture the plug insulator and break electrodes due to the flexing produced by the wave pressure. The excessive temperature and pressure increase can induce serious damage to piston, valves and other engine components. Sparkplug efficiency depends to a great extent upon the amount of voltage available to jump the electrode gap and ignite the intake charge. Even if there is only a weak spark, the mixture will ignite, but flame propagation will be impaired and efficient burning of the intake charge will be reduced.

Many factors are involved where plug voltage is concerned. For instance, increase in compression pressure necessitates increases in voltage pressure. Sparkling voltages will also increase directly with the amount of gap between the electrodes. Temperature also has a pronounced effect on voltage needs. The lower the elecrode temperatures, the higher the voltage necessary to jump the gap.

A temporary rise in voltage will be caused by sudden, full-throttle acceleration. This is due to the sudden increase in compression pressure when the throttle is snapped open. The higher amounts of voltage required at open throttle explains why misfiring occurs during initial periods of sudden acceleration. A defective plug can be checked by applying a certain voltage to the plug while the spark gap is under pressure. Loss of spark continuity or a cracked insulator indicates a bad plug. A plug that is cutting out on a twin can usually be detected by running the bike for a couple of miles and then stopping and feeling the plugs. The "dud" plug will be cooler than the other one.

Such factors as ignition timing and fuel/air ratios cause changes in voltage requirements which greatly affect plug performance and life.

Eve ^ sandblasting new plugs wears away electrode surfaces and surface oxides, increasing voltage. To reduce voltage requirements, electrodes should be filed to present bright, sharp-edged surfaces.

On coil-equipped motorcycles, it is extremely important that the plug's center electrode be of negative polarity. Since electrical current flows from the negative to the positive, the center electrode must be hotter than the ground electrode. Since electrons will jump from a hot surface to a cooler one, the current flows naturally from the center electrode to the ground. But if polarity is reversed when the two low tension wires on the coil are switched, electrons are forced to jump from a cool surface to a hot one.

At low or moderate speeds, the reversed polarity is not too noticeable. But since it takes 45 per cent more voltage to fire a plug with reversed polarity, voltage reserve is reduced. This is especially noticeable during rapid acceleration when compression pressures go up. The spark can't jump across the gap properly and misfiring is the result. At high speeds the points can't stay closed long enough to build up a maximum magnetic field in the coil.

A quick and effective means to check coil polarity is to disconnect the sparkplug cable lead and hold it close to the plug terminal while the engine is running. Insert an ordinary pencil between the terminal and plug lead. If tiny sparks flare out from the pencil toward the plug side, polarity is correctly negative; if the sparks are on the lead side of the pencil, the polarity is positive and wrong.

The two most popular metals used in making electrodes are nickel and platinum. The high lead and sulphur content of modern gasolines make the use of unprotected nickel electrodes impractical. Where high temperatures are involved, sulphur attacks nickel, and above 800 degrees C., complete disintegration of the unprotected nickel results. Plug designers have overcome this by a process known as "chromizing," or, treating the nickel with a diffusion of chromium. This process has eliminated chance of premature failure in the case of center electrodes.

Sparkplugs with platinum electrodes are intended primarily for engines that have widely varying temperatures. Normally, plugs that operate effectively in heavy traffic will have a comparatively short life out on the open road.

Conventional plugs cannot cope efficiently with the wide temperature variations of some ultra-high performance engines. To a large degree, platinum plugs have been successful in coping with this. These plugs are less affected by corrosion and spark erosion. Also, the gaps will hold their intended clearances four times as long as conventional plugs.

One of the most important characteristics of a spark plug is the visible evidence it offers of an engine's operating conditions. The spark plug is an "electrical barometer," so to speak. Though the interpretation of the electrode deposits, accurate analysis can be made to determine the engine's running condition and carburetion status.

If carburetion is correct and the right type of plug is used, under normal temperature conditions, electrode deposits will be of a grayish, flaky nature on the plug body and ground electrode, while a brown or tan colored deposit will be on the center electrode and base of the insulator. If the plug is running hot, the insulator nose will have a bleached appearance with possible ash-colored deposits on plug body.

A plug that is running cold will have oil deposits on the electrodes and base of the insulator. A hotter plug is needed here to burn off the deposits and eliminate the chance of possible short-circuiting. If the carburetion is too rich, the plug will have heavy soot deposits on it.

It must be stressed that if accurate analysis is to be made of the plug to determine whether or not it is of the correct heat range, the engine must be in fairly good condition and not burning oil excessively. Otherwise the plug might be of the correct heat range, but heavy oil deposits from a well-worn engine on electrodes can give false heat range reading.

A carburetor mixture reading can be had by installing a plug (or plugs) of the correct heat range and adopting the following procedures: run the machine for two or three miles in a lower gear and then give the engine a long burst of fullthrottle going up through the gears; kill the engine immediately after shutting off and whipping in the clutch while coasting to a stop.

Plugs should be cleaned at 2-3,000 mile intervals of normal road riding for maximum efficiency. The most effective means is to use the popular sandblast method. Plugs with platinum electrodes can be cleaned this way, but they should not be exposed to prolonged sandblasting. The electrodes are relatively soft, and wear is accelerated by the abrasive compound used for cleaning.

Where two-piece detachable plugs are concerned, sandblasting is preferred to taking the plug apart and cleaning it. There is always danger of not getting a gas-tight fit when reassembling a two-piece plug. A little gasket cement can be used during reassembly to effect a better gastight seal.

There are other methods of cleaning: use of a fine wire brush and fine emery paper; or soaking plugs in kerosene or gasoline to aid in the removal of excess oil and carbon. However, these methods aren't as effective as sandblasting, as there is always danger of not removing all the deposits. Keeping the insulator clean is very important; if it is dirty or damp, the current may jump from the cable to the cylinder head.

When setting the gap on a plug, only the ground electrode should be bent. A wire gauge is preferable to a feeler gauge for getting a correct reading. A plug that is well-worn may have minute "craters" or holes underneath the ground electrode and in the middle of the center electrode. If a feeler gauge is used, it will sit on the sides of the craters and actually give a false reading because the spark is jumping from lowest points or bottoms of craters.

If the ground electrode is bent down at too much of an angle, the spark will jump to its extreme tip and hasten wear. The most effective setting is that of two electrodes facing each other squarely, presenting uniformely flat surfaces offering maximum area for the spark to jump across. An incorrect setting can result in poor idling, fouling, misfiring and powerloss. It always pays dividends to be extracareful when adjusting plug gaps.

To effect a gas-tight seal, it is important that the plug be tightened properly. Each time the plug is re-installed, a new washer should be used. Smearing the plug threads with graphite ensures easy installation and removal of the plug. If difficulty is experienced while trying to remove a rusted plug, let a little penetrating oil seep down around the threads for a few minutes. This makes removal easier.

If the plug is not tightened properly, heat conduction from the plug to the cylinder head will be cut resulting in overheating and pre-ignition. Over-tightening can result in the cylinder head plug hole threads being stripped, especially on aluminum alloy heads. Whenever possible, sparkplugs should be torqued. Correct torque settings are as follows:

18mm 30 foot-pounds torque 14mm 25 foot-pounds torque 12mm 20 foot-pounds torque 10mm 15 foot-pounds torque

In the case of a 14mm plug where the cylinder head plug hole threads are stripped, the hole may be rethreaded to take an 18mm size, space permitting. An alternate method is to have a sparkplug insert fitted by an automotive engine shop which has the necessary equipment for doing such a job.

Sparkplug life varies according to the particular usage of the motorcycle. As a rule, it is false economy to use plugs for more than ten-thousand miles under normal highway conditions. Amazingly enough, a sparkplug can fire as many as thirty million times during its life.

For maximum results, always check your machine's manual or the sparkplug manufacturer's recommendations regarding what type of plug to use. After all, your bike is an expensive investment and the wrong type of plug can decrease the life of an engine in a short time.

Next time you go for a ride, spend a minute and think of what an important job that little sparkplug does; you'll appreciate it a lot more.