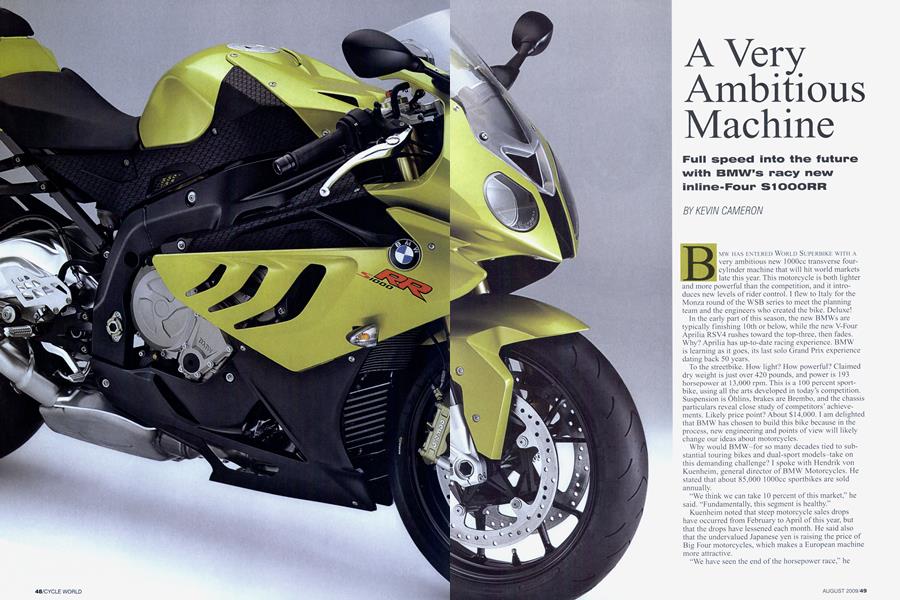

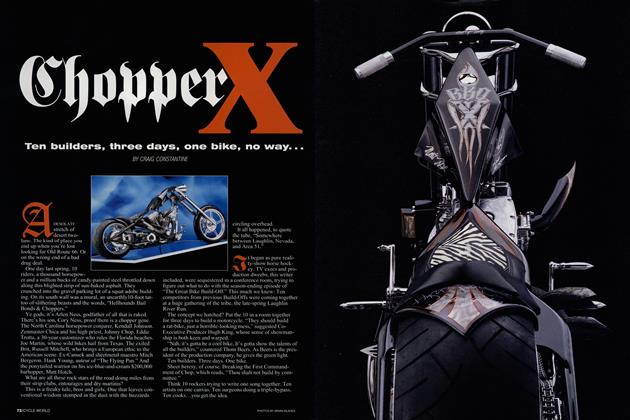

A Very Ambitious Machine

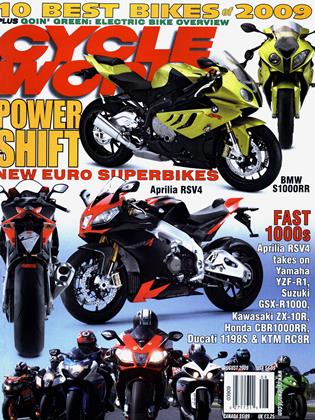

Full speed into the future with BMW’s racy new inline-Four S1000RR

KEVIN CAMERON

BMW HAS ENTERED WORLD SUPERBIKE WITH A very ambitious new 1000cc transverse four-cylinder machine that will hit world markets late this year. This motorcycle is both lighter and more powerful than the competition, and it introduces new levels of rider control. I flew to Italy for the Monza round of the WSB series to meet the planning team and the engineers who created the bike. Deluxe!

In the early part of this season, the new BMWs are typically finishing 10th or below, while the new V-Four Aprilia RSV4 rushes toward the top-three, then fades. Why? Aprilia has up-to-date racing experience. BMW is learning as it goes, its last solo Grand Prix experience dating back 50 years.

To the streetbike. How light? How powerful? Claimed dry weight is just over 420 pounds, and power is 193 horsepower at 13,000 rpm. This is a 100 percent sportbike, using all the arts developed in today’s competition. Suspension is Öhlins, brakes are Brembo, and the chassis particulars reveal close study of competitors’ achievements. Likely price point? About $14,000. I am delighted that BMW has chosen to build this bike because in the process, new engineering and points of view will likely change our ideas about motorcycles.

Why would BMW-for so many decades tied to substantial touring bikes and dual-sport models-take on this demanding challenge? I spoke with Hendrik von Kuenheim, general director of BMW Motorcycles. He stated that about 85,000 1 OOOcc sportbikes are sold annually.

“We think we can take 10 percent of this market,” he said. “Fundamentally, this segment is healthy.”

Kuenheim noted that steep motorcycle sales drops have occurred from February to April of this year, but that the drops have lessened each month. He said also that the undervalued Japanese yen is raising the price of Big Four motorcycles, which makes a European machine more attractive.

“We have seen the end of the horsepower race,” he added. “The future is in driveability.”

BMW S1000RR

This is a sophisticated understanding, central to all development in MotoGP. Power is useless unless you can use it-on the track or on the street. The best lOOOcc sportbike will therefore be the one that is easiest to ride. BMW’s SIOOORR has throttle-by-wire, and the options of what they call RACE ABS and DTC, or Dynamic Traction Control. This latter is second-generation DTC, using lean-angle data generated by the machine’s “sensor cluster.” What we are seeing here is the next step after such systems as Ducati’s eight-level traction control-a move toward complete management of grip during both acceleration and deceleration, modulated for lean angle.

I suspect that as trackside refinement of these systems advances, so will the finish positions of BMW's World Superbike racers Troy Corser and Ruben Xaus. Remember that BMW jumped straight into Formula One and was immediately competitive. This company knows how to make power. The key to using more power on a motorcycle is grip management. The more sharply an engine is tuned, the steeper the ups and downs in its torque curve-and the harder it is for either a rider or a traction-control system to manage it. BMW’s engineers are on this task.

The engine is highly oversquare at 80.0 x 49.7mm bore and stroke-a ratio of 1.61:1. At the stock engine’s power peak of 13,000, this gives moderate 5900-g peak piston acceleration (redline is 14,000). Current piston technology suggests this engine can easily operate at 15,000 rpm in racing form (7850-g piston acceleration, barely higher than in production 600s), and make a possible 230 hp. Power won’t be a problem. Rideability is the central issue.

Valves are generous at 33.5mm intake/27.2mm exhaust, set at a compact 24.5-degree included angle. These valves, with their long 5mm stems, are actuated as in BMW F-l engines by 1 Winch-long radiused finger followers, driven by a pair of hollow forged steel camshafts. Dual cylindrical/helical valve springs are capped by stiff aluminum composite retainers. The valves are lightweight titanium, seated

on copper-containing hard seats. This is an rpm-capable valve drive.

Unique 10mm central sparkplugs are fired by unit coils and have unusually long threaded sections. This allows a fuller wrap of the water space around the exhaust valve seats.

Cam drive is by Morse chain on the right. Primary drive to the cable-operated 10-plate “anti-hopping”

(German for slipper) clutch is by a gear cut into the left crank cheek of the #4 cylinder. A narrow six-speed transmission is drum-shifted, its two shafts vertically stacked to shorten the engine (crank centerline to swingarm pivot is only 9 inches).

The shift shaft crosses the top of the engine to a linkage through the frame on the left. An optional shift drum is required for a racing-style reversed shift pattern.

Short-skirted three-ring pistons operate in Nikasil-onaluminum bores set on 90mm pitch. Cylinders and upper crankcase are cast in-unit.

In line with current practice, these pistons are cooled from below by oil jets. This permits them to be made lighter, as piston crowns otherwise would have to be made thicker to conduct this heat to the cylinder walls. Compression ratio

is a torque-boosting 13.0:1, requiring high-octane premium fuel but monitored by a detonation-control system. Steel cracked-big-end con-rods weigh 334 grams each, have a rod ratio of 2.07:1, and all crank journals measure 34mm ( 1.339 inches). Crank oiling is conventional rather than end-feed.

The steel exhaust system is of 4-into-2-into-l basic construction, but includes butterfly-valved connections between headers 1 and 4, and 2 and 3. This allows use of pipe-wave action from one cylinder to assist cylinder filling in its mate. The collectors of each cylinder pair carry an oxygen sensor and end in a ceramic-core catalyst employing rhodium and palladium. The cats empty into the muffler, located beneath and behind the engine. A single short, open outlet on the right side is further controlled by a large third butterfly valve. The BMS-KP engine controller wisely and mysteriously manipulates these valves to both enhance torque and control noise.

Bare engine weight is remarkably low at 132 pounds. Compare this with the 140-pound weight of the much simpler two-stroke TZ750 of the 1970s-a pure race engine lacking the high four-stroke parts count and the SlOOORR’s electric starter.

Cooling is by a large radiator in the conventional position, with an oil-cooler below it. Oil and water pumps are built as a unit on a single shaft, chaindriven below the gearbox on the right side. Engine oiling is wet sump, with a deep well for the pump pickup between the exhaust collectors. As the temperature of the nearby catalysts can reach 1800 degrees, small airfoil deflectors in the fairing’s chin region direct “strategic cooling” air to this region.

The intake tract is of two-stage variable length. A 2/4-inch piece is moved into position by levers atop the 8%-inch intake tract to boost torque at lower revs. There are two fuel injectors per stackone below each butterfly and one atop each bellmouth in the showerhead position. The four 48mm throttle butterflies are controlled by a stepper motor so that while the Dynamic Traction Control is operating, they move independently of the rider’s throttle. A mechanical linkage allows the rider to directly close the throttle at all times. During warm-up, idle stability is guaranteed by an idle-rpm control.

Think of what a computercontrolled throttle system can do. For reliable tire grip and maximum acceleration, the rider needs smooth, predictable engine torque. Yet only the dullest of industrial engines

actually provides such torque. All sporty engines make use of intake, exhaust and airbox wave action to boost torque, together with valve timings that increase torque in midand high-rpm ranges but thereby weaken it on the bottom. The harder engineers work to boost engine power, the lumpier the torque curve tends to become. This complicates offcorner acceleration, as steep torque spikes spin the tire and “holes” cause delay.

A traditional throttle controls the actual throttle angle, but a computer-controlled throttle interprets the rider’s throttle command as a call for a particular torque level. It uses a look-up table to find the correct throttle angle to produce

the desired torque at the current engine rpm. As the engine accelerates across its torque curve, the throttles close a bit to trim torque spikes and open to fill any holes in the curve. Bingo! The butterflies flutter, keeping output torque at the level the rider sets. The engine-despite any lumps in its natural torque curve—acts smoothly and predictably. This is no different from modern 100-percent-authority aircraft flight controls, which keep aircraft stable even if pilots request the impossible.

Traction control, like BMW’s second-gen DTC, detects rear-tire slip (front and rear wheels have toothed speed sensors) and modulates torque to limit its amount. Modulation is implemented both by ignition retard (instant effect) and by throttle motion.

Four modes of traction control are selectable from the right handlebar: Rain (wet roads), Sport (normal road conditions), Race (track with treaded DOT tires) and Slick (track with slick tires; enabled by insertion of an accessory plug under the seat). In the Rain mode, engine torque is capped at 65 foot-pounds, limiting peak power to 148 hp. To quote from the 42-page press kit, “Race ABS and Dynamic Traction Control are combined with the respective riding modes and coordinated with one another to ensure a supreme standard of performance and safety all in one.”

Moving on: The cast aluminum chassis is robot-welded from four pieces and, with the stout 46mm inverted fork and fashionably long 23.35-inch sheet/cast alloy swingarm, gives a 56-inch wheelbase.

Wheels are 17-inch, 10-spoke cast aluminum, a 3.5-inch front and a 6.0-inch rear, saving weight by bolting brake discs directly to them without separate carriers. Twin 320 x 5mm discs with four-piston radial-mount Brembo calipers brake the front wheel, and a single 220mm disc and two-piston caliper act at the rear. The optional Race ABS combines front and rear braking, and adds about 6 pounds of weight.

Aerodynamic advantages are claimed for this bike. The engine is commendably narrow: 14% inches across the power section and 18% inches including the alternator and cam drive. The real problem is seldom engine width, however, as lOOOcc sportbikes are all 20-21 inches wide. It is the packaging of the rider, who tends to stick out from behind the fairing. In wind tunnel runs I witnessed in 2002, putting the rider on a popular large sportbike added 25 percent to its frontal area. The SIOOORR measures 13% inches across the “uprights”—the vertical members to which the swingarm attaches-and only 10 inches wide across the panels ahead of the seat. Packaging the rider’s legs more narrowly in these ways could very well make a dent in aero drag.

Looking at the chassis in detail, I see that the front of the engine is supported by four slender 6-inch “spikes.” As in MotoGP and current sportbike chassis, these spikes permit the forward part of the frame to flex a few millimeters-as “lateral suspension’-thereby improving front tire contact with the pavement, contributing to front-end feel. At the rear, the same is achieved by making swingarm beams less stiff laterally than they are in twist. Project leader Stefan Zeit told

me that as vehicle-dynamics modeling cannot currently solve such motions, physical experiments are necessary. They tested competitors’ chassis, chose what worked best and then optimized test articles through several build iterations.

Computer modeling was very useful in finding room for all the competing volumes on the machine-airbox, fuel tank, chassis beams and engine parts. Modeling permitted elements to be moved and changed in their shape by millimeters to find optimum arrangements. When this project began more than four years ago, BMW had three people doing computed fluid dynamics. So fruitful has been this kind of modeling that today several more people are working at it. CFD handles problems from combustion speed (modeling in-cylinder turbulence) to through-the-vehicle airflow to whole vehicle aerodynamics.

If horsepower could win World Superbike races, BMW’s knowledge base could easily make 250 hp from this engine. That’s not how it works. More power will be added only as the electronics and software are developed to manage it usefully. The knowledge to be gained in this is priceless for the future that is arriving.

As I look at this new machine, I am struck by how closely it resembles a modern lOOOcc sportbike. It is one. As Herr Kuenheim trenchantly put it, “The market segment is defined,” meaning that the market “knows” what such a bike must look like. This might be a blow to the expectations of some traditional BMW customers (“Where’s my jointed, single-sided swingarm?!”), so company stylist David Robb was at pains in Monza to emphasize the uniqueness of the machine’s styling. The bike looks just fine to me, so the only possible issue is between those customers and Mr. Robb. Basic appearance is defined by the job the machine is designed to do.

BMW’s SIOOORR is a daring but quite necessary step forward in sportbike design because rideabilty is the issue now. I expect great things from this project.

View Full Issue

View Full Issue

More From This Issue

-

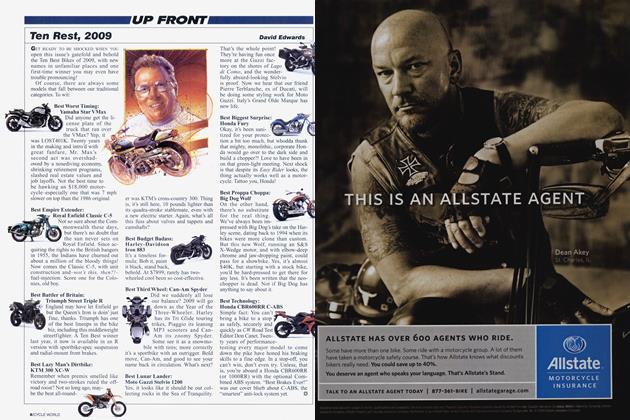

Up Front

Up FrontTen Rest, 2009

August 2009 By David Edwards -

Leanings

LeaningsA Guy of the Moment

August 2009 By Peter Egan -

TDC

TDCInstruments of Control

August 2009 By Kevin Cameron -

Departments

DepartmentsHotshots

August 2009 -

Roundup

RoundupElectric Arrival

August 2009 By Kevin Cameron -

Roundup

Roundup25 Years Ago August 1984

August 2009 By Paul Dean