Gearing for the Best

When Mike Baldwin was racing a TZ750 he put double effort into his choices of gearing. First, he did the usual racer routine of working out the right sprockets for the engine and the track. Second, when he installed the sprockets of his choice he put them on backwards; the numbers showing how many teeth faced inward.

No competitor could stroll casually past Baldwin’s pit and know his gearing. And if anybody was rash enough to bend over the bike and begin counting teeth, Baldwin chased them away.

With good reason. He’d spent time and effort coming up with the gearing he ran. Damned if he'd give that knowledge away.

Professional racers have always been aware of the importance of correct gearing. It may allow them that extra mph down the back straight. Or allow them to shift gears right on the bump in turn Five where the infield runs into the banking at Daytona, where they’d have to back off the throttle anyway. Or perhaps perfect gearing will allow a single gear to be used on an open bike around a motocross track, saving the rider from making any shifts at all.

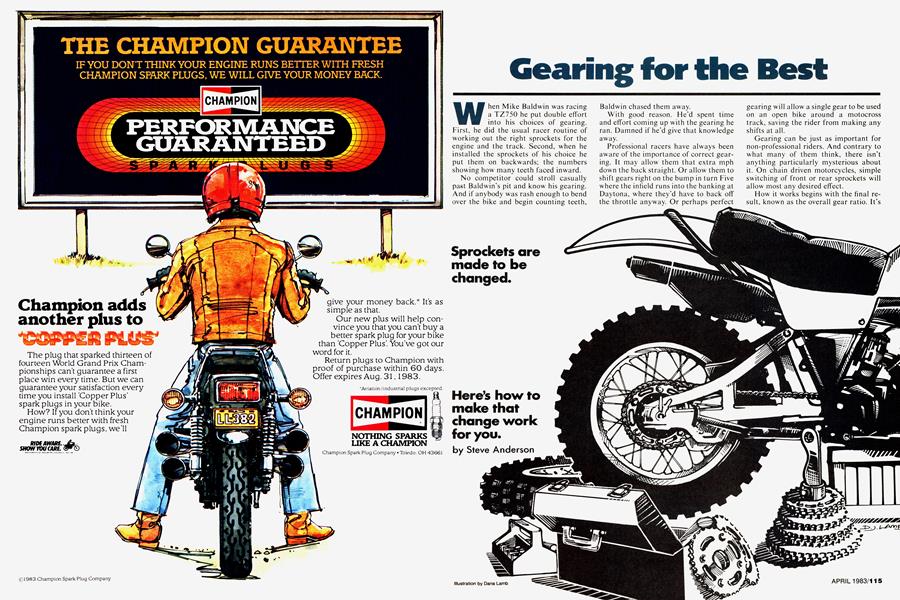

Gearing can be just as important for non-professional riders. And contrary to what many of them think, there isn't anything particularly mysterious about it. On chain driven motorcycles, simple switching of front or rear sprockets will allow most any desired effect.

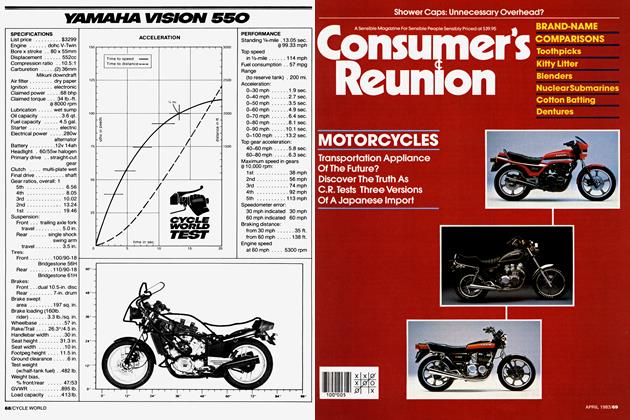

How it works begins with the final result, known as the overall gear ratio. It’s a number we use in test specifications because it’s the one that tells you the difference between the speed of the engine and the speed of the rear wheel.

Steve Anderson

The overall ratio is usually the product of three other ratios. The first set of gears is the primary drive; crankshaft rpm to transmission mainshaft rpm. Next, mainshaft to output shaft or front sprocket; this depends on the which of the gearbox’s speeds is selected, and what that ratio is. Third comes what we’re looking at here, the final drive ratio, which is the difference between the countershaft (or front) sprocket and the rear sprocket.

Depending on engine and intended purpose, the overall drive ratio will be near 5:1. The Harley FXRS represents the low end of the current range at 3.36:1 and the Yamaha XT200 takes the high ground, at 8.54:1.

All this ratio indicates is the number of engine revolutions for each rear tire revolution. The big Harley V-Twin turns over 3.36 times every time its back tire revolves once, and the smaller Yamaha makes 8.54 revolutions as its tire turns once. Because street-going motorcycles have approximately the same rear tire diameter, their rear tires turn about the same speed at 60 mph: 800 rpm give or take about 10 percent. So a quick approximation of the engine speed at 60 mph can be obtained by multiplying the overall gear ratio in top gear by 800 rpm—about 2700 rpm for the Harley, and 6800 rpm for the Yamaha.

There’s a contradiction in gearing terminology. Tall gearing, the type that produces low engine speeds on the highway, comes from low numbers on the overall gear ratios. Low, or short, gearing that buzzes the engine at cruising speeds is associated with high gear ratio numbers. There’s not much to do about the terminology problem but remember the lower the overall gear ratio, the lower the engine rpm at any given road speed.

There’s also not much you can do about the first two parts of our gearing triple play. The factory picks the primary drive ratio on the basis of engine torque, number of gearbox speeds and room inside the cases, and that takes care of that.

It's nearly the same for the intermediate gears inside the transmission. Some of the motocross bikes will allow a swap, as in five small speeds for four big ones or vice versa. Older road racers will remember the options for Triumph and BSA gearboxes and H-D has complete gearsets to juggle but most of the time, no. What the factory gave you for 1st through 5th or 6th is what you’ll keep.

All right. What you can do with a chain drive machine, and all you really will need to do, is tailor that final drive ratio to your own personal needs.

Suppose for example you have a powerful bike and you travel light, mostly in level country. You can lower the engine speed for the same road speed by fitting a larger, that is one or more added teeth, front sprocket or a smaller rear sprocket.

Got a smaller bike with big fairing and a need for camping gear for trips to the mountains? You can ease the engine’s burden and reduce the number of downshifts by using a smaller front sprocket or a larger rear.

How much change are we talking about? It’s strictly proportional to the ratio of old sprocket size to new sprocket size. If a motorcycle started life with a 40 tooth rear sprocket, and turned 5000 rpm at 60 mph, a 38 tooth rear sprocket would have a 38/40, or .95, ratio to the original sprocket, and the engine rpm would drop to 5000 x .95, or 4750 rpm. A similar speed reduction could be achieved by a front sprocket change. If the same motorcycle originally had a 17 tooth front sprocket, and an 18 tooth were substituted while keeping the 40 tooth rear sprocket, the new cruising rpm would be 17/18 x 5000 rpm, or 4722 rpm. If you wanted a motorcycle engine to turn faster on the highway, the opposite approach would be required: a smaller front sprocket, or a larger rear sprocket. The proportional relationship between sprocket size and engine speed would still apply.

There are several practical considerations when making gearing changes. First, unless a machine is being used in a

radically different way than its designers intended, gearing shouldn’t be changed by more than 10 or 15 percent. When taller gearing than standard is run, the load on the entire drive train is increased, and the engine is more likely to ping and detonate. Both effects are undesirable, and are made worse as the gearing varies further from stock. Alternatively, as an engine is geared to run fast at cruising speeds, other trade-offs are made. Rollon acceleration may be increased, but higher engine speeds mean more wear and higher oil temperatures. Fuel economy will likely drop. All these are reasons not to change gearing dramatically from the original ratio. Second, the largest possible countershaft sprocket should be used for increased efficiency and chain life. The individual chain links are forced to rotate more relative to each other as they travel around a smaller sprocket, increasing wear in the chain. So if taller gearing is chosen, the desirable change is a larger countershaft sprocket. If shorter gearing is chosen, it's better to raise the rear sprocket size and leave the countershaft sprocket alone. Third, if changes of more than one or two teeth are made, there may not be enough adjustment of the rear wheel position to allow the stock length chain to be used. A longer or shorter chain may be required. Finally, the sprocket material should be considered. The standard rear sprockets of most bikes are steel. Many aftermarket rear sprockets are aluminum. The aluminum sprockets weigh only a third as much as a steel sprocket, but generally won’t last as long. They’re better suited for competition than touring.

Non-professional racers can also gain advantages with correct gearing, and from our observations of local motocross and club level road races, these are advantages only used by the people leading the races. The first consideration is installing gearing that allows the bike to reach its maximum speed down the fastest straight. This results when the engine is running at, or just slightly over, peak power rpm in top gear at the fastest point on the track. (Peak power rpm can be very different from the engine’s red line; refer to magazine tests or the manufacturer’s power claim to determine at what speed the engine makes the most power.)

It’s obviously easier to gauge if a road racer equipped with a tachometer is operating at optimum engine speed than a motocrosser, but it’s equally important for both. If a bike is running past its power band in top, install taller gearing. If it’s barely making it into top gear, gear down.

After a race bike is geared for top speed for a given track, there still may be reason for subtle changes to the gearing. The object of racing, after all, is to beat everyone else around the race track, not to set fast speed down the straight. Sometimes lap times drop when gearing is set to give good drives out of important corners rather than just for top speed. Also, the gearing that works right for the drives and the straights might force you into a shift at an awkward time and place, like in the middle of a turn. Or it could mean you’ve wound the engine too tight in 2nd while it bogs in 3rd. In some cases alternate gearing can cure this while not messing up the rest of the lap.

Some caution here, though. It’s possible to come out of the turn with the fast guys and find your engine wound past the max on the straight while they pull away. Aha, you say, I need taller gearing. Go too far and you gain some top speed while ruining that perfect drive. The tip for all this gearing work is to have your crew working the watches, so you’ll know when top speed is worth it and when it’s not. When you’re tuning gearing to this extent, a gearing chart will also be an aid; such a chart should show final drive gear ratios with different sprocket combinations and give peak speed in each gear for each final drive ratio. The chart is required to see the “in between” gear ratios that can be achieved by changing both the front and rear sprocket simultaneously.

Our resident motocross expert suggests that four additional sprockets will cover the range of gearing required at different motocross tracks: two countershaft sprockets, the first one tooth smaller and the second one tooth larger than stock, and two rear sprockets, one two teeth smaller than the original sprocket, the other two teeth larger. A similar selection would be a good start for production class road racers. And remember, after gearing is settled on for a given track, a change in rear tire brand can result in a gearing change. Tires which are nominally the same size from different manufacturers may vary enough in diameter to change gearing as much as a two tooth different rear sprocket would.

All of the discussion of gearing alternatives to this point has applied to chain drive motorcycles, and that’s because there are fewer alternatives for shaft drives. BMW alone offers a wide range of ring and pinion gear sets of different ratios for the final drive. They're much more expensive than sprockets, but at least they’re available. Various models of Moto Guzzis have an internal gearset that can be changed to vary the overall gear ratio. With Japanese shaft drive bikes, you had better like the stock gearing, as there is no reasonable way to change it. The best that can be done is to vary the gearing slightly by switching to a rear tire with a slightly different overall diameter; this approach is limited by the constraints of tire clearance, ground clearance, and handling. The inflexibility of shaft drives explains the advent of wide-ratio six speed gearboxes on many of the new Honda modelsif you can’t change the final drive ratio, at least you can have a gear for every occasion.

GEARING CALCULATIONS

Resulting engine speed in rpm from teeth new sprocket changing the rear sprocket rpm before change X teeth old sprocket Resulting engine speed in rpm from teeth old sprocket changing the front sprocket rpm before change X teeth new sprocket Road speed at a given engine speed teeth old sprocket after a rear sprocket change speed before change X teeth new sprocket Road speed at a given engine speed teeth new sprocket after a front sprocket change speed before change X teeth old sprocket Engine speed at 60 mph overall gear ratio X rear tire rpm @ 60 mph Rear wheel rpm at 60 mph same as rear tire revolutions per mile* primary drive ratio X individual gear ratio Overall gear ratio X final drive ratio (X any other drive ratios for engines that transmit power through jackshafts) Speed in mph at any given 60 X engine rpm - roverall gear ratio in engine speed in any given gear given gear -rrear tire revs per mi. Engine speed in rpm at any road speed in mph X overall gear ratio in given road speed in any given gear given gear X rear tire revs per mi. -r60 *Rear tire revolutions per mile are given tire to note each wheel revolution. After a in some tire manufacturers’ literature; certain number of revolutions (say 5 or 10 starting with the June issue, we’ll give this for accuracy), stop the motorcycle with measured quantity in our road tests. The the tape on the tire once again under the technique for measuring rear tire revolurear axle. Mark this spot on the ground tions per mile is as follows: place the with another piece of tape, and measure motorcycle on a section of flat pavement. the distance between the two tape pieces With a piece of tape, mark the point on on the ground. Tire revolutions per mile the rear tire directly under the axle, and are then given by: 1/(distance between with another piece of tape, mark this tape pieces in ft. H5280 Htire revopoint on the ground. Roll the motorcycle lutions.) For most motorcycle tires, this forward, using the piece of tape on the number should be close to 800.