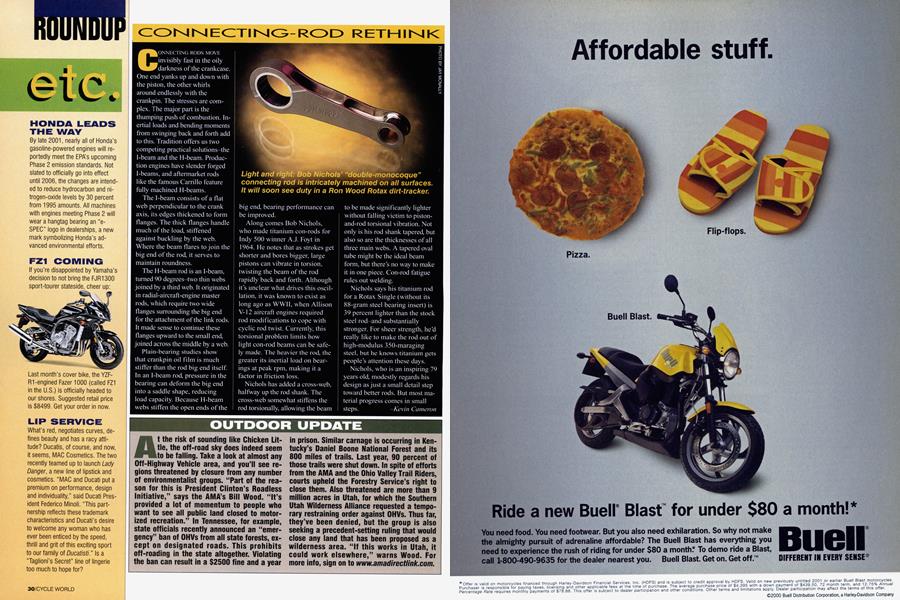

CONNECTING-ROD RETHINK

ROUNDUP

CONNECTING RODS MOVE invisibly fast in the oily darkness of the crankcase.

One end yanks up and down with the piston, the other whirls around endlessly with the crankpin. The stresses are complex. The major part is the thumping push of combustion. Inertial loads and bending moments from swinging back and forth add to this. Tradition offers us two competing practical solutions-the I-beam and the H-beam. Production engines have slender forged I-beams, and aftermarket rods like the famous Carrillo feature fully machined H-beams.

The I-beam consists of a flat web perpendicular to the crank axis, its edges thickened to form flanges. The thick flanges handle much of the load, stiffened against buckling by the web. Where the beam flares to join the big end of the rod, it serves to maintain roundness.

The H-beam rod is an I-beam, turned 90 degrees-two thin webs joined by a third web. It originated in radial-aircraft-engine master rods, which require two wide flanges surrounding the big end for the attachment of the link rods. It made sense to continue these flanges upward to the small end, joined across the middle by a web.

Plain-bearing studies show that crankpin oil film is much stiffer than the rod big end itself. In an I-beam rod, pressure in the bearing can deform the big end into a saddle shape, reducing load capacity. Because H-beam webs stiffen the open ends of the big end, bearing performance can be improved.

Along comes Bob Nichols, who made titanium con-rods for Indy 500 winner A.J. Foyt in 1964. He notes that as strokes get shorter and bores bigger, large pistons can vibrate in torsion, twisting the beam of the rod rapidly back and forth. Although it’s unclear what drives this oscillation, it was known to exist as long ago as WWII, when Allison V-12 aircraft engines required rod modifications to cope with cyclic rod twist. Currently, this torsional problem limits how light con-rod beams can be safely made. The heavier the rod, the greater its inertial load on bearings at peak rpm, making it a factor in friction loss.

Nichols has added a cross-web, halfway up the rod shank. The cross-web somewhat stiffens the rod torsionally, allowing the beam to be made significantly lighter without falling victim to pistonand-rod torsional vibration. Not only is his rod shank tapered, but also so are the thicknesses of all three main webs. A tapered oval tube might be the ideal beam form, but there’s no way to make it in one piece. Con-rod fatigue rules out welding.

Nichols says his titanium rod for a Rotax Single (without its 88-gram steel bearing insert) is 39 percent lighter than the stock steel rod-and substantially stronger. For sheer strength, he'd really like to make the rod out of high-modulus 350-maraging steel, but he knows titanium gets people’s attention these days.

Nichols, who is an inspiring 79 years old, modestly regards his design as just a small detail step toward better rods. But most material progress comes in small steps.

Kevin Cameron

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontCafé Society

December 2000 By David Edwards -

Leanings

LeaningsOrthopedic Bike

December 2000 By Peter Egan -

TDC

TDCPaying the Price

December 2000 By Kevin Cameron -

Departments

DepartmentsHotshots

December 2000 -

Roundup

RoundupKawasaki Goes Green

December 2000 By Matthew Miles -

Roundup

RoundupEnter the Drako?

December 2000 By Brian Catterson