Burning race

TDC

Kevin Cameron

DETONATION IS MORE THAN AN ANnoying rattling noise coming from your engine. The rattling is caused as sonic-speed shock waves hit metal surfaces, displacing the insulating boundary layer of stagnant gas that normally protects cylinder and piston from rapid heat transfer. Robbed of this insulation, parts heat up and aluminum softens. Struck by the shock waves, soft metal is blasted away. Not good.

Combustion in gasoline engines is always a race between two competing chemistries. The first is actual combustion itself-the heat-driven breakup of fuel and oxygen molecules, and their violent recombination as water, carbon dioxide and carbon monoxide. The other occurs in the as-yet-unbumed part of the fuel-air charge. As the combustion flame expands, spread from the sparkplug gap by turbulent charge motion, the unbumed charge is compressed and rapidly heated by it. So-called “pre-flame reactions” occur in this heated but unbumed charge. Thermal collisions knock hydrogen atoms off of fuel molecules. Oxygen molecules-normally pairs of atoms more interested in each other than in other arrangements-are broken apart in the same way.

Because the unburned mixture is merely hot and not actually burning, these chemical changes don’t release enough heat to achieve hot combustion. More chemistry has to take place first. The oxygen and hydrogen atoms recombine to form new species such as OH-. These chemical fragments are called “radicals,” and they are highly reactive. As continuing normal combustion further compresses and heats the remaining unbumed charge, the populations of these new species increase. This changes the nature of the unburned charge. As it first formed, from the evaporation of fuel droplets from carburetor or fuel injector into the intake air stream, the mixture was chemically stable-not going to ignite simply because fuel and oxygen were present together.

The unbumed charge in our engine, now at a high temperature as the flame front whirls nearer, has been chemically altered by the heat. Given time enough, the population of reactive radical species rises to a critical value, at which time parts of the remaining unburned mixture self-ignite and bum at or above the local speed of sound. This is detonation.

The higher the temperature to which the unburned charge is exposed, the longer it takes the flame front to reach and burn that charge, the more likely detonation becomes. If normal combustion is fast enough, it wins the race by burning up the whole charge before any part of it can detonate. If combustion takes longer, heat-driven pre-flame reactions somewhere in the unburned charge may win, causing those death-rattles.

To avoid the knocks, rapid combustion is essential in high-output engines. To obtain maximum torque from an engine, compression is normally raised right to the threshold of detonation. What determines that threshold? It is determined by how much the unburned charge is heated in the engine, and how long that heating continues.

Anything that heats the fresh charge tends to make detonation more likely. This includes initial inlet air temperature, the cooling effect of fuel evaporation, the temperature of the intake manifold, of the combustion chamber (especially the very hot exhaust valves) and of the piston crown.

The second big factor is time. The longer it takes to complete combustion, the longer the yet-unbumed part of the charge cooks its way toward detonation, the lower the maximum compression ratio that the engine can tolerate. The faster combustion can be made, the higher the compression ratio can safely be made.

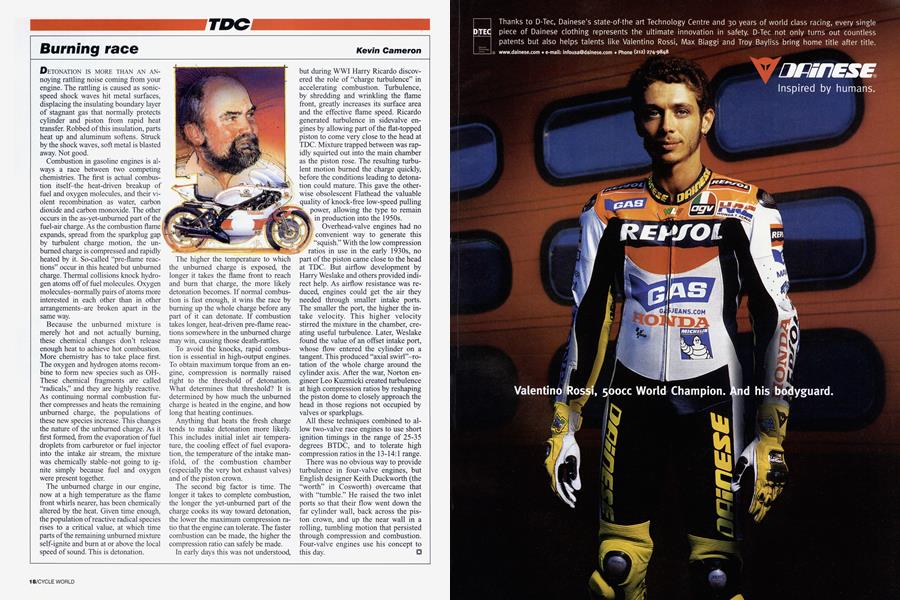

In early days this was not understood, but during WWI Harry Ricardo discovered the role of “charge turbulence” in accelerating combustion. Turbulence, by shredding and wrinkling the flame front, greatly increases its surface area and the effective flame speed. Ricardo generated turbulence in sidevalve engines by allowing part of the flat-topped piston to come very close to the head at TDC. Mixture trapped between was rapidly squirted out into the main chamber as the piston rose. The resulting turbulent motion burned the charge quickly, before the conditions leading to detonation could mature. This gave the otherwise obsolescent Flathead the valuable quality of knock-free low-speed pulling power, allowing the type to remain x in production into the 1950s.

Overhead-valve engines had no convenient way to generate this squish.” With the low compression ratios in use in the early 1930s, no part of the piston came close to the head at TDC. But airflow development by Harry Weslake and others provided indirect help. As airflow resistance was reduced, engines could get the air they needed through smaller intake ports. The smaller the port, the higher the intake velocity. This higher velocity stirred the mixture in the chamber, creating useful turbulence. Later, Weslake found the value of an offset intake port, whose flow entered the cylinder on a tangent. This produced “axial swirl”-rotation of the whole charge around the cylinder axis. After the war, Norton engineer Leo Kuzmicki created turbulence at high compression ratios by reshaping the piston dome to closely approach the head in those regions not occupied by valves or sparkplugs.

All these techniques combined to allow two-valve race engines to use short ignition timings in the range of 25-35 degrees BTDC, and to tolerate high compression ratios in the 13-14:1 range.

There was no obvious way to provide turbulence in four-valve engines, but English designer Keith Duckworth (the “worth” in Cosworth) overcame that with “tumble.” He raised the two inlet ports so that their flow went down the far cylinder wall, back across the piston crown, and up the near wall in a rolling, tumbling motion that persisted through compression and combustion. Four-valve engines use his concept to this day.

View Full Issue

View Full Issue