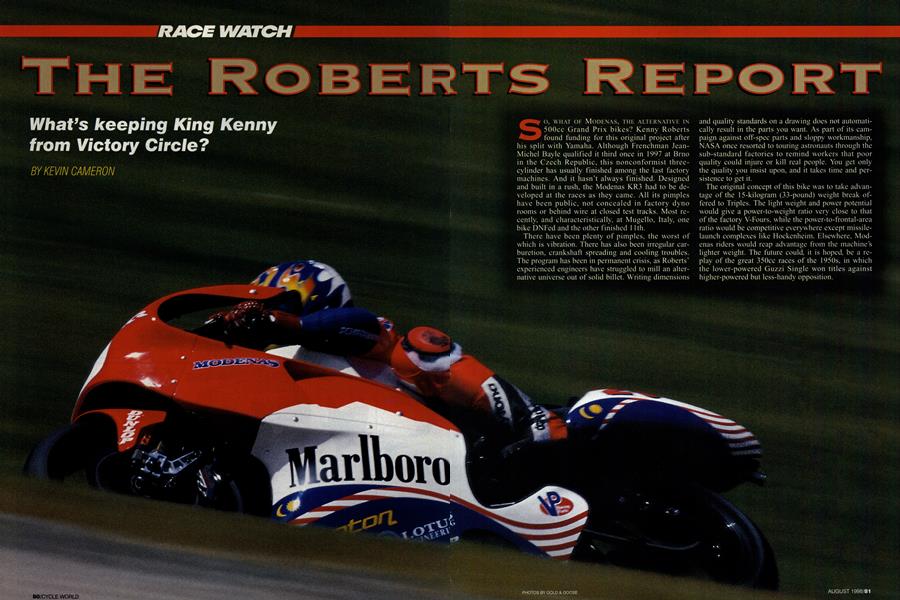

THE ROBERTS REPORT

RACE WATCH

What's keeping King Kenny from Victory Circle?

KEVIN CAMERON

SO, WHAT OF MODENAS, THE ALTERNATIVE IN 500cc Grand Prix bikes? Kenny Roberts found funding for this original project after his split with Yamaha. Although Frenchman JeanMichel Bayle qualified it third once in 1997 at Brno in the Czech Republic, this nonconformist threecylinder has usually finished among the last factory machines. And it hasn't always finished. Designed and built in a rush, the Modenas KR3 had to be developed at the races as they came. All its pimples have been public, not concealed in factory dyno rooms or behind wire at closed test tracks. Most recently, and characteristically, at Mugello, Italy, one bike DNFed and the other finished 11th. There have been plenty of pimples, the worst of which is vibration. There has also been irregular carburetion, crankshaft spreading and cooling troubles, The program has been in permanent crisis, as Roberts' experienced engineers have struggled to mill an alternative universe out of solid billet. Writing dimensions cally and quality result standards in the parts on you a drawing want. As does part not of automatiits eampaign against off-spec parts and sloppy workmanship, NASA once resorted to touring astronauts through the sub-standard factories to remind workers that poor quality could injure or kill real people. You get only the quality you insist upon, and it takes time and persistence to get it. The original concept of this bike was to take advantage of the 15-kilogram (33-pound) weight break offered to Triples. The light weight and power potential would give a power-to-weight ratio very close to that of the factory V-Fours, while the power-to-frontal-area ratio would be competitive everywhere except missilelaunch complexes like Hockenheim. Elsewhere, Modenas riders would reap advantage from the machine's lighter weight. The future could, it is hoped, be a rcplay of the great 35()cc races of the 1950s, in which the lower-powered Guzzi Single won titles against higher-powered but less-handy opposition.

The original concept of this bike was to take advantage of the 15-kilogram (33-pound) weight break offered to Triples. The light weight and power potential would give a power-to-weight ratio very close to that of the factory V-Fours, while the power-to-frontal-area ratio would be competitive everywhere except missilelaunch complexes like Hockenheim. Elsewhere, Modenas riders would reap advantage from the machine's lighter weight. The future could, it is hoped, be a rcplay of the great 35()cc races of the 1950s, in which the lower-powered Guzzi Single won titles against higher-powered but less-handy opposition.

At the end of the '97 season, there were rumors that retired engineers Mr. Oguma (Honda) and Mr. Maekawa (Yamaha) had offered to redesign the engine for lower vibration. At Daytona this spring, Roberts responded to my question on this by cheerfully evading it with, "That's a rumor!" A new lower-end is in the works, and the team has taken on more of its manufacturing, rather than farming it out as previously done to TWR and other "Formula-One Zone" specialists. Team Roberts is strategically located in Banbury, England, in the heart of F-l country.

Roberts himself is hard to reach ("He's somewhere in Europe, on his way to Italy," I was told), so I talked to staffer Chuck Aksland, son of the team's highly respected, long-time engine-development chief, Bud Aksland.

I asked Chuck about vibration with the existing layout, and about the rumor that it had prevented the bike from reaching the minimum weight limit, simply because the frame and other components had to be overbuilt to deal with the shaking. "It made it difficult, yes," he said. "We've got the vibration down to a degree, but until you put in a balance shaft (you still have problems). Vibration is like a tornado-you never know where it's going to hit. Now that we've reduced the vibration and im proved reliability, we've been able to get some weight off the bike."

Each cylinder of a reciprocating engine produces an up-and-down shaking force. If there is more than one cylinder, these forces can be opposed, added in such a way as to cancel some or all of this shaking. Piston motion-and therefore, the shaking force-is determined by two variables: crankpin height and the changing angle of the con-rod. The crankpin rises and falls once per revolution, leading to primary imbalance. Rod angularity change imposes a smaller, twice-per-revolution variation in piston height, leading to secondary imbalance. Typically, secondary forces are about 25 percent of primary forces.

A three-cylinder engine can have perfect primary and secondary balance by phasing the separate shaking forces of the three cylinders at 120 crank degrees, causing them to add to zero. The cylin ders do not have to be in line for this to be the case. This allowed DKW and Honda to build three-cylinder racing en gines, each with its center cylinder out of line with the other two. In the case of the Deek, the out-of-line angle was 75 degrees, and for Freddie Spencer's Honda NS500, 110 degrees. In the case of the Modenas, it is close to 180 de grees, with two outer cylinders sloping forward and down, and the center cylin der sloping upward and back.

Perfect primary and secondary balance means only that an engine does not leap up and down or back and forth. Despite this, Triples do rock from side to side, caused by the fact that the three vibration vectors are not acting in the same plane, but are separated from each other by the cylinder spacing. Primary rocking was canceled in the case of the Honda by a crankspeed balance shaft, resulting in an engine smooth enough to be successfully used in early aluminum chassis.

In the Modenas, another design goal was to reduce weight and bearing friction. To achieve this, one pair of cylinders shares a common crankcase. To give equal crankcase pumping to the two cylinders, both pistons come to TDC together, thanks to slightly staggered crankpins. A similar crankcase sharing scheme is used on the Swiss auto/ELF/MuZ V-Four. Between the two con-rods of these cylinders is an unsupported flywheel disc, bored for crankpins forged in unit with the adja cent flywheels. This sharing elimi nates one flywheel disc and at least one main bearing and crankcase bear ing saddle and web, but the shared disc carries double stress and is sup ported only by the crankpins that press into it from each side.

In the KR3's initial design, it was assumed that rubber mounts allowing enough freedom of motion would take care of the rocking couple. Let it rock! With this in mind, no provision was made for a crank-speed balance shaft to cancel the rocking. This neglects the effect on the carburetors, which mount to the engine, and the result was an inconsistent and unpredictable mixture. When you watch the fuel in a transparent float bowl as an old-style parallelTwin is revved up-even with soft rubber carb mounts-you see it climb the walls and sometimes explode into fog. In the course of development, many different balance schemes have been tried, and there were some fairsized failures like broken footpeg plates and fairing mounts. Varying the balance percentages has moved the problem around, but I'm told, "It's pretty good right now." The revised engine-to appear this season-will have a balance shaft.

Team Roberts has resisted balance shafts, assuming they add rotating inertia, bearing friction and weight. They do, but as has been discovered with many other racing and production engines, the weight of the balancer is less than the weight (and unreliability) that can be saved by not having to so strongly reinforce the chassis and other parts to survive the vibration.

Another balance problem mentioned in connection with the Modenas is socalled "deflection imbalance." A wellbalanced but weak or oddly loaded crank can, as it revs up, generate stresses that deflect it, causing imbalance that would not exist at low revs. This could be the case with the Modenas' shared flywheel, but Chuck Ak sland says this is a really rigid engine. Its pistons won't hit the heads at the really small squish clearance of 0.5mm. Early reported problems with crankshaft spreading (creeping apart of the pressed joints) were cured by using tighter press-fits.

This year, the team consists of Kenny Roberts Jr., as before, while Bayle's place was taken by 250cc front-runner Ralf Waldmann. A switch was made from Michelin to Dunlop (Waldmann is a long-time Dunlop stalwart), and the two bikes have appeared in contrasting colors, provoking questions about sponsorship relations.

I asked how Team Roberts came to have the riders that it does. Roberts has in the past expressed doubts as to the suitability of riders who come direct to 500s from 250s, yet for 1998 he has two such riders.

"Basically, Kenny Junior is on the team for a number of reasons," said Aksland. "First of all, he grew up training and riding the way Kenny and Wayne (Rainey) did." That means steering with the throttle, in contrast to 250cc GP-style, high corner speeds. "But our bike depends on corner speed (to achieve a good lap time), and Junior's having to adapt to thatit's not the way he grew up. As the bike gets better (more acceleration, and less dependence on corner speed), he'll get better." Rider choice is not a simple matter of signing the hottest available man, one optimally suited to your equip ment. The sponsor "buys" racing as a sales tool, and may insist on a partic ular individual or nationality to achieve sales goals in particular mar kets. There may be compromises here, but GP racing is business, not an afternoon of sport with the chaps. "Waldmann was agreed upon with the sponsor, for reasons having to do with nationality," Aksland added. "Ralf is one of the guys who met the criteria. We'd met him before; he trained at the ranch.

"Ralf is sponsored by Marlboro, so his bike says ‘Marlboro Team Roberts,'" Aksland continued. "Junior is sponsored by Proton (Malaysianmade Nissan cars) and Modenas (a Malaysian motorcycle manufacturer), and he has (personal) sponsorship from Philip Morris, so his bike just says ‘Team Roberts.'"

I inquired about the effects of the Far Eastern currency crisis. "They (Proton and Modenas) have chosen to stay. They understand the long-term benefits of our program. Regardless (of the higher costs associated with devaluation), it's still a good program for them-the benefits outweigh the costs," claimed Aksland.

Rising companies in the Far East need worldwide recognition, and GP racing is one way to achieve this. It did, after all, work for Mr. Honda back in 1959.

Roberts told me at Daytona that the team is making more parts in-house, using its own people and machine tools. "We still have a lot of components done out, (although) we are doing some of that now," he said. "Some from the States, some from Malaysia, some in England. That's the way it's done now, everywhere. If they make a better component in Italy than they do in France, we'll use the Italian one. Proton, in Kuala Lumpur, they are using rapid prototyping and we are using that."

Rapid prototyping creates a three-dimensional object directly from a computer file. Such an object can be used for study, or can be made as a casting pattern, allowing very short times be tween design and hard parts.

What's it like sending computer files globally, making everything fit to standards, I asked? Aksland replied, "We're still learning about that! That's where the future is going: files over the Internet-CAD files and drawings."

Another aspect of the Modenas was a long-awaited departure in cooling. Traditional radiators are placed between the front wheel and engine, not because there is good inlet and outlet airflow there (there isn't), but because there is room. There is a vicious cycle of needing more cooling because the traditional location is bad, forcing the use of monster radiators that cause even more drag, requiring more power to overcome it. More power means more heat, equals more radiator, ad infinitum. The practical, observant men on Team Roberts wanted something better, and therefore adopted the under-seat-mounted, ducted-radiator layout previously seen on the Britten and Saxon Triumph.

A jet engine is a device that takes in air at low volume and low velocity, then heats it and ejects it rearward at higher volume and higher velocity. A well-designed radiator and duct system is potentially a low-thrust jet engine. In the case of the best radiator setups on WWII aircraft-the British Mosquito and U.S. P-51, for example-the installation develops enough thrust to cancel its flow loss. The Modenas team wanted this advantage.

So far, the cooling system hasn't been an advantage, forcing a return to the conventional. Early season races in the Far East are hot, hot, hot. This doesn't mean ducted cooling can't work. It just means it hasn't been done right yet.

Trying to do things differently means going without the experience of the conventional way. But after a period of solving start-up problems, the Modenas team may soon give its original concepts a fair test by reaching the de sign weight, with consistent carbure tion, good cooling and tolerable vibration. Let us hope the new bottomend arrives soon, bringing a stable plat form on which Bud Aksland's hard work (cylinders, heads and pipes) can do its job, while the riders-no longer seeing double-can do theirs.

View Full Issue

View Full Issue