Tread aggression

TDC

Kevin Cameron

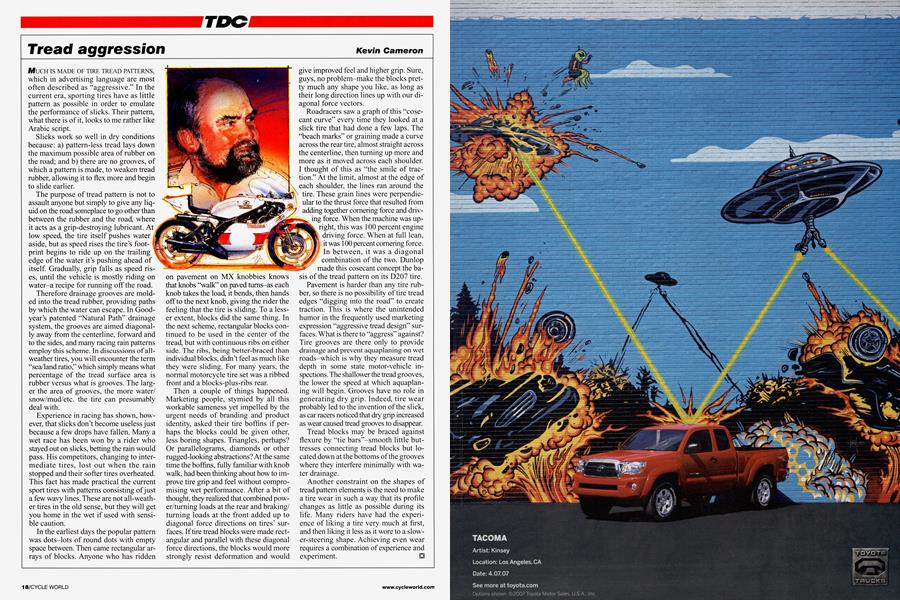

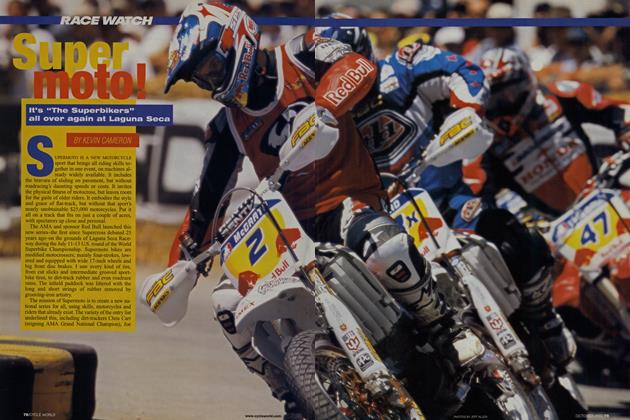

MUCH IS MADE OF TIRE TREAD PATTERNS, which in advertising language are most often described as “aggressive.” In the current era, sporting tires have as little pattern as possible in order to emulate the performance of slicks. Their pattern, what there is of it, looks to me rather like Arabic script.

Slicks work so well in dry conditions because: a) pattern-less tread lays down the maximum possible area of rubber on the road; and b) there are no grooves, of which a pattern is made, to weaken tread rubber, allowing it to flex more and begin to slide earlier.

The purpose of tread pattern is not to assault anyone but simply to give any liquid on the road someplace to go other than between the rubber and the road, where it acts as a grip-destroying lubricant. At low speed, the tire itself pushes water aside, but as speed rises the tire’s footprint begins to ride up on the trailing edge of the water it’s pushing ahead of itself. Gradually, grip falls as speed rises, until the vehicle is mostly riding on water-a recipe for running off the road.

Therefore drainage grooves are molded into the tread rubber, providing paths by which the water can escape. In Goodyear’s patented “Natural Path” drainage system, the grooves are aimed diagonally away from the centerline, forward and to the sides, and many racing rain patterns employ this scheme. In discussions of allweather tires, you will encounter the term “sea/land ratio,” which simply means what percentage of the tread surface area is rubber versus what is grooves. The larger the area of grooves, the more water/ snow/mud/etc. the tire can presumably deal with.

Experience in racing has shown, however, that slicks don’t become useless just because a few drops have fallen. Many a wet race has been won by a rider who stayed out on slicks, betting the rain would pass. His competitors, changing to intermediate tires, lost out when the rain stopped and their softer tires overheated. This fact has made practical the current sport tires with patterns consisting of just a few wavy lines. These are not all-weather tires in the old sense, but they will get you home in the wet if used with sensible caution.

In the earliest days the popular pattern was dots-lots of round dots with empty space between. Then came rectangular arrays of blocks. Anyone who has ridden on pavement on MX knobbies knows that knobs “walk” on paved tums-as each knob takes the load, it bends, then hands off to the next knob, giving the rider the feeling that the tire is sliding. To a lesser extent, blocks did the same thing. In the next scheme, rectangular blocks continued to be used in the center of the tread, but with continuous ribs on either side. The ribs, being better-braced than individual blocks, didn’t feel as much like they were sliding. For many years, the normal motorcycle tire set was a ribbed front and a blocks-plus-ribs rear.

Then a couple of things happened. Marketing people, stymied by all this workable sameness yet impelled by the urgent needs of branding and product identity, asked their tire boffins if perhaps the blocks could be given other, less boring shapes. Triangles, perhaps? Or parallelograms, diamonds or other rugged-looking abstractions? At the same time the boffins, fully familiar with knob walk, had been thinking about how to improve tire grip and feel without compromising wet performance. After a bit of thought, they realized that combined power/turning loads at the rear and braking/ turning loads at the front added up to diagonal force directions on tires’ surfaces. If tire tread blocks were made rectangular and parallel with these diagonal force directions, the blocks would more strongly resist deformation and would give improved feel and higher grip. Sure, guys, no problem-make the blocks pretty much any shape you like, as long as their long direction lines up with our diagonal force vectors.

Roadracers saw a graph of this “cosecant curve” every time they looked at a slick tire that had done a few laps. The “beach marks” or graining made a curve across the rear tire, almost straight across the centerline, then turning up more and more as it moved across each shoulder.

I thought of this as “the smile of traction.” At the limit, almost at the edge of each shoulder, the lines ran around the tire. These grain lines were perpendicular to the thrust force that resulted from adding together cornering force and driving force. When the machine was upright, this was 100 percent engine driving force. When at full lean, it was 100 percent cornering force. In between, it was a diagonal combination of the two. Dunlop made this cosecant concept the basis of the tread pattern on its D207 tire.

Pavement is harder than any tire rubber, so there is no possibility of tire tread edges “digging into the road” to create traction. This is where the unintended humor in the frequently used marketing expression “aggressive tread design” surfaces. What is there to “aggress” against? Tire grooves are there only to provide drainage and prevent aquaplaning on wet roads-which is why they measure tread depth in some state motor-vehicle inspections. The shallower the tread grooves, the lower the speed at which aquaplaning will begin. Grooves have no role in generating dry grip. Indeed, tire wear probably led to the invention of the slick, as car racers noticed that dry grip increased as wear caused tread grooves to disappear.

Tread blocks may be braced against flexure by “tie bars”-smooth little buttresses connecting tread blocks but located down at the bottoms of the grooves where they interfere minimally with water drainage.

Another constraint on the shapes of tread pattern elements is the need to make a tire wear in such a way that its profile changes as little as possible during its life. Many riders have had the experience of liking a tire very much at first, and then liking it less as it wore to a slower-steering shape. Achieving even wear requires a combination of experience and experiment.