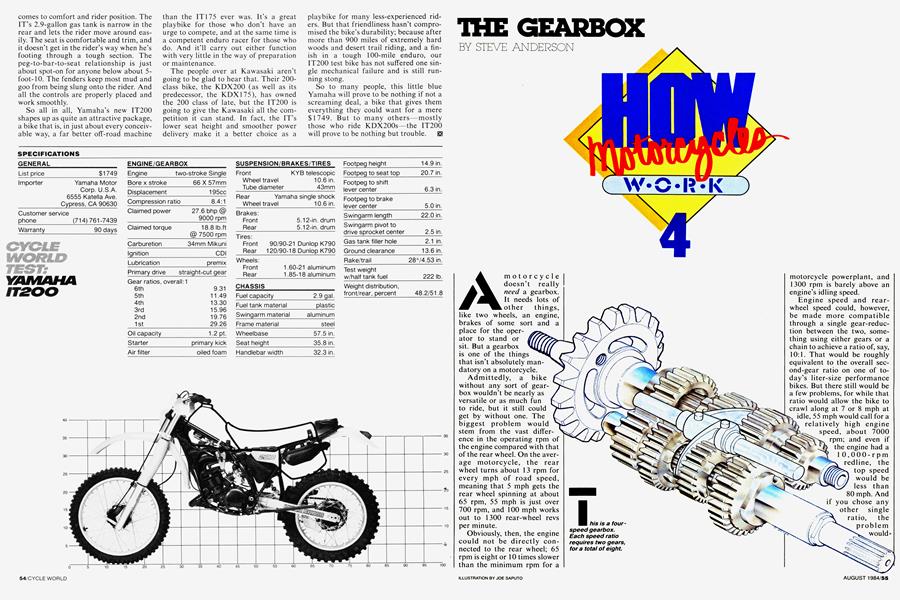

HOW MOTORCYCLES W·O·R·K 4

THE GEARBOX

STEVE ANDERSON

A mtorcycle doesn't really need a gearbox. It needs lots of other things, like two wheels, an engine, brakes of some sort and a place for the operator to stand or sit. But a gearbox is one of the things that isn't absolutely mandatory on a motorcycle.

Admittedly, a bike without any sort of gearbox wouldn’t be nearly as versatile or as much fun to ride, but it still could get by without one. The biggest problem would stem from the vast difference in the operating rpm of the engine compared with that of the rear wheel. On the average motorcycle, the rear wheel turns about 13 rpm for every mph of road speed, meaning that 5 mph gets the rear wheel spinning at about 65 rpm, 55 mph is just over 700 rpm, and 100 mph works out to 1300 rear-wheel revs per minute.

Obviously, then, the engine could not be directly connected to the rear wheel; 65 rpm is eight or 10 times slower than the minimum rpm for a motorcycle powerplant, and 1 300 rpm is barely above an engine’s idling speed.

Engine speed and rearwheel speed could, however, be made more compatible through a single gear-reduction between the two, something using either gears or a chain to achieve a ratio of, say, 10:1. That would be roughly equivalent to the overall second-gear ratio on one of today’s liter-size performance bikes. But there still would be a few problems, for while that ratio would allow the bike to Trawl along at 7 or 8 mph at idle, 55 mph would call for a relatively high engine speed, about 7000 rpm; and even if the engine had a 1 0,000-rpm redline, the top speed would be less than 80 mph. And if you chose any other single ratio, the problem would* be the same: The engine rpm would be ideal for one particular range of road speeds but not for all ranges.

The solution, of course, is to use more individual gear ratios so engine rpm can be better matched to rear-wheel rpm under all conditions. Starts are easier, top speeds are higher and cruising rpm is more reasonable if there is a selection of gear ratios available. Multiple gear ratios also result in vastly improved acceleration by allowing the engine to be kept running within its most powerful rpm range.

There’s a catch, though: It is impossible to physically unbolt the gears or sprockets connecting the engine to the rear wheel and bolt on different ones, all while the bike is moving. So, what’s needed is some way for the rider to change ratios while he’s in motion. What’s needed is a gearbox.

Knowing what a gearbox does and why it’s there, however, doesn't explain how it works. And perhaps the simplest way to take care of that problem is not to begin by trying to understand what goes on inside of a modern fiveor six-speed gearbox; instead, let’s just dream up a hypothetical motorcycle that has a simple, two-speed gearbox. Imagine that rather than having one long chain connecting the engine to the rear wheel, this imaginary bike has a shorter chain linking the engine’s crankshaft to the front shaft (called the input shaft) of a gearbox located just behind the engine, and another chain connecting the rear wheel to the rear shaft (called the output shaft) of the gearbox. The input shaft and output shaft are parallel to one another and, in the case of a two-speed gearbox, are fitted with four separate gears, two on each shaft.

For low-speed operation, the gear on the input shaft usually is considerably smaller than its mate on the output shaft; for the sake of explanation, let’s just say that lowgear's input-shaft gear has 10 teeth and its output-shaft gear has 20 teeth. That results in a 2:1 ratio, which means that in low gear, the input shaft must turn twice to make the output shaft turn once. And for the high-gear ratio, let’s merely* reverse the gear sizes: 20 teeth on the input gear and 10 on the output gear. That yields a 0.5:1 ratio, meaning that in high gear, one revolution of the input shaft will turn the output shaft twice.

In theory, this two-speedy gearbox partially overcomes the difficulty that a singlespeed machine has in covering the required range of road speeds. If we inserted this gearbox, for instance, into they aforementioned single-speed motorcycle that had a 10:1 engine-to-rear-wheel ratio, we'd end up with a 20:1 low-gear ratio (10:1 x 2:1) and a 5:1 high-gear ratio ( 10:1 x 0.5:1 ). That would, of course, makok for an unusually wide ratiogap between gears. But the solution to that problem is the one currently employed by all motorcycle manufacturers: use more ratios.

Regardless of the number of ratios, however, all gearboxes have one thing in com-.« mon: They can only be in one gear at a time. If both of the ratios in our two-speed box were engaged simultaneously, something would break—gear teeth, gearbox shafts or all of the above—because each input-shaft gear is trying to turn the output shaft at a different^ speed. A gearbox therefore must have some means of connecting only one gearset at a time while disconnecting all the other gearsets.

One way to accomplish this*“ selective gear engagement is to make one of our gearbox’s two shafts—the input shaft, for example - square for most of its length, and round only at its very ends where it fits into the bearings that support it. The two gears on the input shaft each have a matching square hole in the middle so that they have to turn at the same speed as the shaft but are free to slide from side to side. The two output-shafk gears, though, are permanently affixed to their shaft so that they always turn at the same speed as the shaft but cannot move from side to side.

Disconnecting a gearset now is quite easy. To engage^ low gear, you just move high gear’s input-shaft gear side--> ways until its teeth no longer ^mesh with those of its mate on the output shaft. That disconnects high gear but still leaves the low-gear pair meshed. Shifting into high gear involves nothing more than moving low gear’s input-shaft gear sideways until its teeth are out of mesh, then sliding high gear back into mesh with its mate.

This method requires a mechanical claw of some sort, commonly known as a “shift fork,” on each input-shaft ’'gear to slide it into and out of mesh with its mate. The movement of the forks is controlled by a linkage connected to a foot-operated shift lever. One end of each shift fork fits into a narrow slot cut circum^ ferentially around its inputshaft gear, and the other end rides in a wide groove cut into either a flat plate (called a camplate) or, on most modern motorcycles, a round cylinder (called a shift drum). When vthe foot lever is moved, the shift linkage causes the drum to rotate (or the camplate to change position); and the drum/camplate grooves are machined so they cause the appropriate shift forks to slide their respective gears into or out of mesh.

< At this point, we’ve assembled all the pieces necessary to make a functional two-speed gearbox. In theory, anyway. But in actual practice, such a gearbox would have serious shifting problems due to the need to slide the gears into and out of mesh. The necessary clearances between meshed gear-teeth have to be so microscopically small that the mating gears will slide into mesh only when the teeth on one gear are lined up ex' actly with the spaces between the teeth on the other gear.

Any time this perfect alignment doesn’t happen which is just about alwaysthere will be a glitch in the shifting. If the rear wheel is stopped *■ and the engine is off, neither the input nor the output shaft are turning; so if the gear teeth don’t happen to align perfectly at that point, the teeth will bang together and the gearbox will quietly refuse

Íto if engage the gears the chosen and shafts gear. But are turning which is the case any time the engine is running and/or the rear wheel is turning any mating gears that are unmeshed usually are spinning at such vastly different speeds that their gear teeth either are never perfectly aligned or are never aligned at all. Thus, an attempted shift under these circumstances generally is accompanied by a missed shift or by the graunching and grinding of gear teeth against one another.

Many early cars and motorcycles used this type of gearbox that moves gears into and out of mesh. The noise these transmissions made during shifts earned them the nickname “crashboxes.” Ultimately, dissatisfaction with such crude methods of ratioselection led to the development of a gearbox that keeps all of its gears meshed at all times: the “constant-mesh” gearbox.

Converting our hypothetical crashbox into a constantmesh gearbox would be relatively simple. The input shaft would need to be redesigned so it was round over most of its length and square only for a short span in its middle. The round part allows the inputshaft gears which have matching round holes in the middle to spin freely on the shaft. But those input-shaft gears would not be able to slide from side to side, the purpose being to keep them constantly meshed with their mates on the output shaft.

So far, what we’ve described is a gearbox full of neutrals only; for until there is some way to lock the input shaft’s free-spinning gears to the shaft, the gears cannot transmit any power. So we’ll spread those two input-shaft gears a short distance apart and fit between them a special ring, which we’ll call a shifting ring. This ring has a square hole in the middle so it can fit over the square portion of the input shaft, meaning that it must rotate with the shaft; the ring is free, however, to be slid from side to side as dictated by the shift fork. The ring also has pegs (called “dogs,” for reasons long-lost in history) projecting from both sides, and those pegs can fit into slots cut into the inner faces of the two input-shaft gears.

For the sake of explanation, let’s just say that the left-side gearset in our two-speed gearbox provides the low-gear ratio, and that the right-side set provides the high-gear ratio. To engage low gear, the shift fork slides the shift ring to the left until the pegs in the left side of the ring plug into the slots in the input shaft’s lefthand gear. That effectively locks that gear to the shaft, inasmuch as the shifting ring is now locked to both, while the right-side (high-gear) gear is still free-spinning. The gearbox is now in low gear. Shifting to high gear is accomplished simply by sliding the ring to the right, which first disengages the input shaft’s left-side gear and then engages the right-side gear. The gearbox is now in high gear. And if the shift ring is positioned between the two inputshaft gears but is not plugged into either one of them, the gearbox is in neutral.

Constant-mesh gearboxes like this one inherently shift more easily, positively and quietly than do crashboxes. This is because the clearance between shift-ring dogs and gear slots can be much larger than the minute clearance between gear teeth. It’s not uncommon, in fact, for some engagement slots to be three or four times longer than the dogs that fit into them. This generous clearance means there’s a much greater likelihood of immediate engagement any time a shift is attempted, resulting in an almost total absence of missed shifts and graunching noises. The trade-off, though, is that the added dog-to-slot clearance also causes a considerable increase in the amount of> backlash present in the driveline.

Many motorcycles have used constant-mesh gearboxes similar to this one except, of course, that they incorporated more than just two ratios. Almost without exception, one gearset (comprised of one gear on the input shaft and one on the output shaft) is required for each ratio; thus, a five-speed box needs 10 individual gears. And rather than using a square-section shaft to prevent gears or shift rings from spinning freely while allowing them to slide side-toside, most gearboxes use splines of some sort to accomplish the same thing more elegantly.

Most modern motorcycles, however, use constant-mesh gearboxes that are more compact than the type depicted here. They do that by eliminating the separate shifting rings and incorporating the engagement dogs right into the gears themselves. In a typical six-speed box, for example, three of the 12 individual gears function as engagement devices in addition to providing three separate ratios. These gears have dogs on both sides and can be slid back and forth to engage the gears they sit between. Also, just like the shifting rings they replace, those sliding gears are splined to the shaft on which they ride, while the gears on either side of them are free-spinning. But the real secret behind this concept is to have gear teeth (either on the sliding gear or on the gear it meshes with on the other shaft) that are wide enough so the sliding gear will still be at least 50-percent meshed with its mating gear when slid to either side far enough to achieve complete engagement.

The particular kind of gearbox we’ve been describing here is called an all-indirect gearbox, which is by far the most common type in use today. It derives its name from the fact that the engine’s power never passes directly through it without flowing through one gearset. In all gears, the power enters the gearbox through the front (input) shaft, passes through one pair of gears, and exits the gearbox through the rear (output) shaft.

But there is another type of transmission, called a directdrive gearbox, that allows the power to pass from input to output without ever going through a single gearset—although it does so only in high gear. The key difference between this and the all-indirec^ type is that even though a direct-drive gearbox also hasY two shafts, the power enters and exits on essentially the same shaft. The front shaft actually is two shafts that run on the same centerline, a trick that usually is accomplishecF by making one shaft hollow and fitting the other shaft inside of it.

Thus, the power enters the gearbox through this two-part shaft's input segment (which is the largest part, for it con* tains the input half of the gearsets for all gears othery than high), and is transferred to the rear shaft through whichever of the gear pairs is engaged. The power then flows into the other (output)* segment of the two-part shaft through a special set of gears A that do nothing but transfer the power from the rear shaft to the output shaft. In high gear, however, a set of engaging dogs locks the concentric input shaft and output shaft together so they turn as one.'The power therefore enters and exits on what is effectively the same shaft, bypassing the rear shaft altogether.

Fundamentally, though, an all-indirect and a direct-drive gearbox both employ the same, kinds of gear-engagement principles and, with one notable exception, use the same component terminology. That exception is the rear gearbox shaft, which on an all-indirect box is called either an output shaft or, more commonly, a countershaft. The latter name refers to the fact that the output shaft’s direction of rotation is “counter” to that of the input shaft. The rear shaft is counter-rotating in a directdrive gearbox, as well, but in that application it’s called a layshaft, most likely because it doesn’t do anything but “lay" alongside the input shaft (generally called a mainshaft on both types of gearboxes) and help provide gear-reductions.

A direct-drive gearbox has its advantages compared with the all-indirect type, as well as certain disadvantages. Its biggest benefit is that in top gear -the one in which a motorcycle spends most of its Running time — the direct drive allows a higher level of efficiency, a lower level of gear noise and less driveline lash than can be had with an all-indirect box. In the other gears, though, a direct-drive box is anything but direct, because the power must flow through two separate gearsets between entry and exit. Consequently, an all-indirect box is slightly more efficient in all but high gear simply because it forces the power to flow through only one gear-pair at a time.

Throughout the years, though, the kind of gearbox used on any given motorcycle has been dictated more by the bike’s primary drive than by the advantages or disadvantages of either design. You see, a chain-type primary drive makes the crankshaft and the input shaft both turn in the same direction; a gear primary makes them turn in opposite directions. That was a significant difference to engine designers, who used to feel that the crankshaft had to turn in the same direction as the wheelsusually for reasons concerning things like crankshaft torque-reaction, direction of con-rod angularity during the exhaust stroke, availability of ignition/generator components capable of rotating in the other direction, etc. With chain drive, that criteria is met by a direct-drive gearbox; with gear drive, it’s met by the all-indirect box.

This explains why British bikes, which inherited their chain-type primary drives from predecessors that had separate engines and transmissions, used direct-drive gearboxes. In fact, a large number of European-built motorcycles either have used or still do use chain primaries and direct-drive gearboxes, while most Japanese machines have gear primary drives and all-indirect transmissions.

These days, engine technology and component availability have advanced to the point where concerns about the direction of engine rotation are no longer valid (except for motocross bikes and most other off-road motorcycles, which, due to crankshaft torque-reaction, tend to feel too nose-heavy if their cranks rotate “backwards”). As a result, an engine designer will make a crankshaft rotate in whatever direction is necessary to allow him to use the most suitable type of gearbox.

Among the other factors that a gearbox designer must take into account is the profile of the engagement dogs. Somehow, he has to find the right balance between dogs whose sides are parallel and those whose sides are slightly dovetailed (also called “undercut,” meaning that they’re wider at the outside end than at the inside). When adjacent gears that have undercut dogs are attempting to make engagement, the angularity of the undercut surfaces working against one another tends to draw the gears together and assist in completing the shift; and once the shift is complete, the undercut tends to hold the gears securely in engagement. On the other hand, having too much undercut — or sometimes, any at all can cause the gears to resist disengagement, which can result in stiff shifting. So in the end, determining the proper undercut requires a bit of educated guessing refined through a process of trial-and-error on a prototype gearbox.

Same goes for the choice of gear ratios. To make the best use of all the available speeds in a gearbox, each individual ratio must be carefully selected to work with the engine’s power characteristics. First gear needs to be low enough to allow easy starts, even when the bike is carrying two people and is starting off on a steep upgrade. Top gear must be high enough to allow easy running at normal cruising speeds, yet not so tall that the engine has difficulty accelerating or maintaining speed up slight grades. And all the gears in between low and high should be staged fairly evenly so that there are no large ratio gaps that could be difficult for the powerband to span.

Actually, the relationship between gear ratios and engine powerbands is a lot like the old chicken-and-egg theory: It’s hard to say which came first. Having more than one gear ratio has allowed engine designers to develop more highly tuned engines with narrower powerbands, which in turn prompted the use of more gear ratios, which then encouraged higher states of tune resulting in even narrower powerbands, and so on.

So while it is true that motorcycle engines might not need gearboxes, it’s hard to imagine how they could get along without them. Because without gearboxes, today’s bikes wouldn’t be...today’s bikes. 0

View Full Issue

View Full Issue