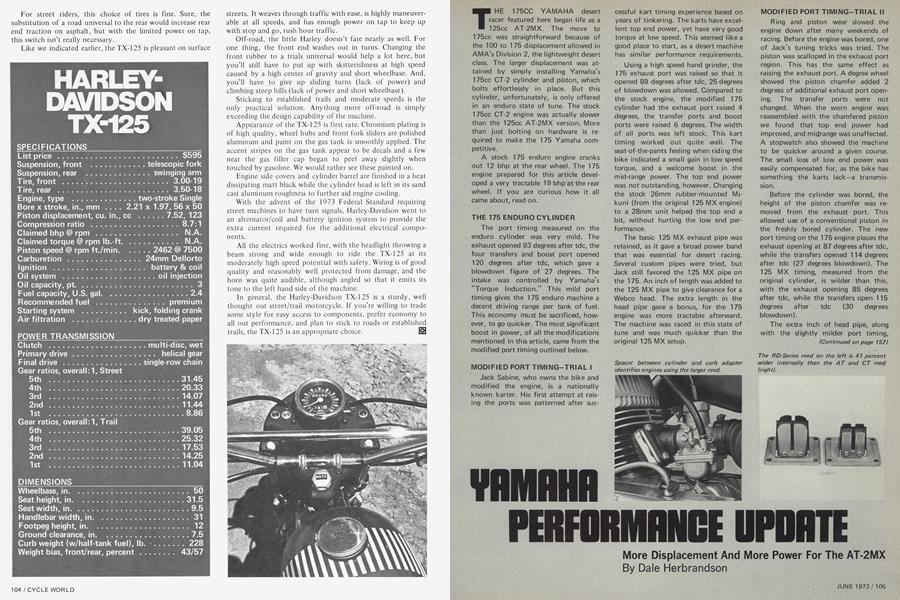

YAMAHA PERFORMANCE UPDATE

More Displacement And More Power For The AT-2MX

Dale Herbrandson

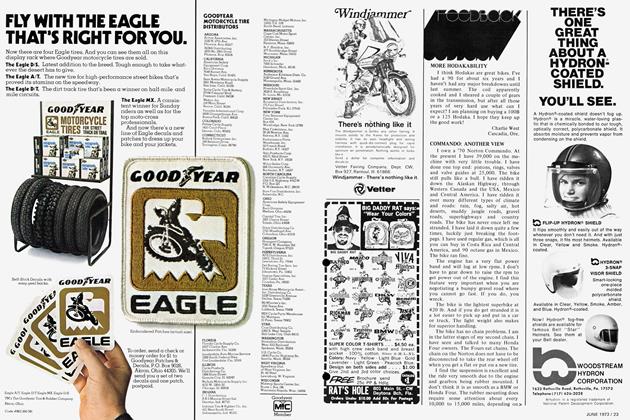

THE 175CC YAMAHA desert racer featured here began life as a 125cc AT-2MX. The move to 175cc was straightforward because of the 100 to 175 displacement allowed in AMA's Division 2, the lightweight desert class. The larger displacement was attained by simply installing Yamaha's 175cc CT-2 cylinder and piston, which bolts effortlessly in place. But this cylinder, unfortunately, is only offered in an enduro state of tune. The stock 175cc CT-2 engine was actually slower than the 125cc AT-2MX version. More than just bolting on hardware is required to make the 175 Yamaha competitive.

A stock 175 enduro engine cranks out 12 bhp at the rear wheel. The 175 engine prepared for this article developed a very tractable 19 bhp at the rear wheel. If you are curious how it all came about, read on.

THE 175 ENDURO CYLINDER

The port timing measured on the enduro cylinder was very mild. The exhaust opened 93 degrees after tdc, the four transfers and boost port opened 120 degrees after tdc, which gave a blowdown figure of 27 degrees. The intake was controlled by Yamaha's "Torque Induction." This mild port timing gives the 175 enduro machine a decent driving range per tank of fuel. This economy must be sacrificed, however, to go quicker. The most significant boost in power, of all the modifications mentioned in this article, came from the modified port timing outlined below.

MODIFIED PORT TIMING-TRIAL I

Jack Sabine, who owns the bike and modified the engine, is a nationally known karter. His first attempt at raising the ports was patterned after suc-

cessful kart timing experience based on years of tinkering. The karts have excellent top end power, yet have very good torque at low speed. This seemed like a good place to start, as a desert machine has similar performance requirements.

Using a high speed hand grinder, the 175 exhaust port was raised so that it opened 89 degrees after tdc, 25 degrees of blowdown was allowed. Compared to the stock engine, the modified 175 cylinder had the exhaust port raised 4 degrees, the transfer ports and boost ports were raised 6 degrees. The width of all ports was left stock. This kart timing worked out quite well. The seat-of-the-pants feeling when riding the bike indicated a small gain in low speed torque, and a welcome boost in the mid-range power. The top end power was not outstanding, however. Changing the stock 26mm rubber-mounted Mikuni (from the original 125 MX engine) to a 28mm unit helped the top end a bit, without hurting the low end performance.

The basic 125 MX exhaust pipe was retained, as it gave a broad power band that was essential for desert racing. Several custom pipes were tried, but Jack still favored the 125 MX pipe on the 175. An inch of length was added to the 125 MX pipe to give clearance for a Webco head. The extra length in the head pipe gave a bonus, for the 175 engine was more tractable afterward. The machine was raced in this state of tune and was much quicker than the original 125 MX setup.

MODIFIED PORT TIMING-TRIAL II

Ring and piston wear slowed the engine down after many weekends of racing. Before the engine was bored, one of Jack's tuning tricks was tried. The piston was scalloped in the exhaust port region. This has the same effect as raising the exhaust port. A degree wheel showed the piston chamfer added 2 degrees of additional exhaust port opening. The transfer ports were not changed. When the worn engine was reassembled with the chamfered piston we found that top end power had improved, and midrange was unaffected. A stopwatch also showed the machine to be quicker around a given course. The small loss of low end power was easily compensated for, as the bike has something the karts lack—a transmission.

Before the cylinder was bored, the height of the piston chamfer was removed from the exhaust port. This allowed use of a conventional piston in the freshly bored cylinder. The new port timing on the 175 engine places the exhaust opening at 87 degrees after tdc, while the transfers opened 114 degrees after tdc (27 degrees blowdown). The 125 MX timing, measured from the original cylinder, is wilder than this, with the exhaust opening 85 degrees after tdc, while the transfers open 115 degrees after tdc (30 degrees blowdown).

The extra inch of head pipe, along with the slightly milder port timing, makes the 175 engine very tractable. It does not come on the pipe as uncomfortably hard as the 125 MX engine. The extra 50cc also makes the 175 easier to ride.

(Continued on page 157)

Continued from page 105

Unfortunately, the Yamaha still did not have a great deal of power. Everything on the engine looked fine, except the reed. Could “Torque Induction” be slowing us down?

THE STOCK REED

The reed used in the 175 CT-2 engine is the same small unit as is found in the 125cc AT-2 and 3 engines. The width of each of the four holes in the reed cage is 0.425 in., with a lift at the tip of the reed of 0.275 in. The product of height and width gives area. The total area normal to the direction of flow is 0.47 sq. in. If we ignore flow coefficients, this area is equivalent to a hole less than 20mm in diameter! Here we were using a 28mm carburetor with a 20mm diameter bottleneck in the air flow. A larger need appeared to be in order. Luckily, one was available at Yamaha dealers.

THE RD-SERIES REED

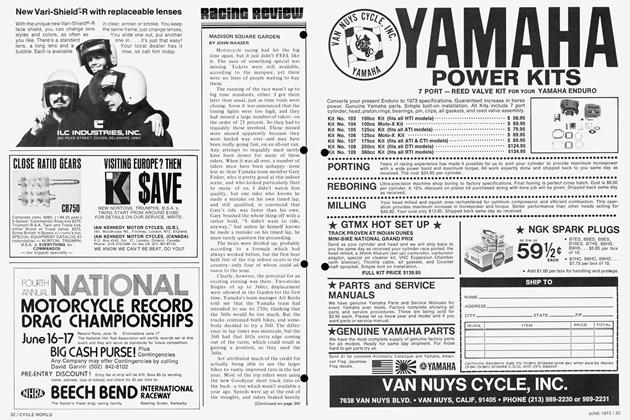

Yamaha recently introduced a 250 and 350 Twin with reed induction. These new engines for 1973 have a reed that is 41 percent wider internally than the one found in the AT or CT reed engines. The bolt hole spacing on the RD reed is the same as the AT and CT reed, which makes an easy conversion. Unfortunately, the RD reed is too long and too wide to fit directly into the cavity on the AT or CT reed engines. The drawing in Figure 1 shows that a

10mm thick spacer is required to do the job properly. The spacer is available from DH Enterprises, 1605 Lynngrove Drive, Manhattan Beach, CA 90266. Metal removal also is required to get the wide reed into the small AT or CT cavity. The spacer should be used as a > Continued from page 157 guide when removing metal. Be sure and check the tips of the RD series reed petals, when installed in the AT or CT cylinders. The reed petals must have clearance to survive. The RD-series reed also fits the 125 cylinder—if the DH spacer is used and metal is removed from the cylinder.

The big RD reed assembly was exactly what the 175 engine needed to pick up the top end performance. In addition to pulling better through the gears, the big reed allowed the engine to rev higher. It added at least 5 mph to the flat out speed. The modified 175 revs so easily it gives the rider mixed emotions. It is exhilarating to feel and hear the engine sing through the gears, but one wonders if it will hold up. However, there have been no problems with over a year of racing on the engine.

The very fast Noguchi cylinders have been using the RD reed valve for over a year now. The big reed undoubtedly is responsible for much of the advantage the Noguchi speed parts hold over the stock equipment. Installation of the RD reed valve into the AT or CT cylinders actually builds a poor man's Noguchi racing cylinder.

CARBURETION

As mentioned already, the rubbermounted 28mm Mikuni carburetor is preferred over a 26mm unit on the 175 engine, and is greatly superior to the 24mm bolt-on unit found on the 175 enduro. Experience from other 175 reed engines which have been built by DH Enterprises suggests that a 30 to 34mm carburetor would give better power. The larger carburetors can't be fitted to the Yamaha without a hassle, however. The 26 and 28mm Mikuni share a common > body size which has a 35mm spigot diameter (the spigot fits into the RDseries rubber carb adapter). The 32 and 34mm rubber mounted Mikuni's have a larger body using a 40mm spigot, which is too big for the RD-series carburetor adapter. The big body also has a large float bowl which interferes with the crankcase on the AT and CT engines. The big carburetor bodies just won't fit properly.

The 28mm venturi can be bored to 28.5mm. Any further increase in size ruins the carburetor as the 30mm diameter slide will not seal the hole properly. This increase in area is less than 4 percent—it's hardly worth the time. A stock 28mm carburetor should be used on the AT and CT engines.

Once the decision is made to use an unaltered 28mm rubber-mounted Mikuni, the rest is simple. The 1973 RD-250 and RD-350 engines both use a 28 Mikuni. A RD-250 carb (Yamaha No. 361-14101-00-00) should be used on the 125 AT series, and a RD-350 carb (Yamaha No. 360-14101-00-00) should be likewise used on the 175 CT engine. The only difference in carburetors is the jet size. Ordering the proper carb from Yamaha saves jetting time. Be sure and order the left carburetor, which has the choke. The fitting which feeds the "choke mixture" to the right carburetor on the RD Twin must, of course, be plugged for use on the single-cylinder engines.

The stock 125 MX air filter is used on the 175 racer. The air hose has a rather severe bend after leaving the air box. The bend is created when routing the hose around the frame's down tube. The dyno shows that this causes no problem as far as power goes. Of course, several accessory manufacturers offer different types of filtration units, if you so desire.

CONCLUSIONS

The 175cc desert racer presented here is a rather inexpensive machine to build. It has proven to be reliable and easy to maintain. Plastic fenders, aluminum sprockets, and other straightforward changes give a relatively light machine at 193 lb. (dry).

In sand or uphill running the prepared 175 Yamaha is at least as fast as the other 175 units around. It is very competitive in the power-to-weight department. Some bikes, admittedly, have more top speed. In a sand wash, however, the prepared 175 Yamaha is very quick—and best of all, it is affordable. 0