CABLES AND LEVERS

A Case For Upside Down Levers With Enough Cable Theory Thrown In To Cover Any Modification Required—Even If You Own A Famed Hungarian Zilch./By Carl Shipman

FRIEND, YOU have your control levers installed upside down. The ones on the handlebar, I mean.

You say your levers are installed just the way they were when the bike came from the factory, and just like the levers on every other bike. Emphatically.

I don't care. You still have them on upside down.

You may have two questions. One: Have you encountered a lunatic? Two: Is it possible that some motorcycle factories install levers upside down?

The answers are no and yes, respectively. To understand why requires a look at cables and how they fail. Then, you may decide to join the loonies and turn your levers over.

Figure 1 shows a rope passing through a sewer pipe. Please watch your end while I pull on my end. If I pull out a foot of rope, your end gets shorter by one foot. Seems about as complicated as a club. That's the way control cables work, isn't it?

No, it isn't. Because the sewer pipe didn't do anything. Your end of the rope would have moved just the same without the pipe. The outer cover, or conduit, of a control cable has a function, or it wouldn't be there. The function is not to keep the inner cable nice and clean.

Figure 2 provides a clue. The rope is not straight. Please hold your end while I pull on my end. The rope straightens out a little as a result of my tug, but your end didn't move at all. Now, we're getting somewhere, although not at any great velocity. A function of the conduit is to define a curved path for the cable so it can't just straighten out. Also, the conduit must not change length and it must flex to some degree.

Figure 3 will not surprise you. If the conduit is rigidly mounted at each end, and not compressible, l can pull the inner cable out an inch at one end and it will become shorter by an inch at the other end. It works, but a bad guy has gotten under the bed. Friction.

If you think of a force pulling on each end of the cable in Figure 3, it will be apparent that the cable is trying to straighten out, every place that it is curved. This causes it to snuggle against the inside of the conduit with a force which becomes higher as the radius of the curve is decreased. This force against the side of the conduit results in friction.

If the cable is in motion, due to pulling in the clutch lever perhaps, there could be 10 lb. of force at one end of the cable and only 5 lb. of force “coming out" the other end. The other 5 lb. of force would be used in overcoming friction between the cable and conduit. This is why nylon-lined cables work well and why lubricated cables work better than dry cables.

Some riders oil cables faithfully, perhaps every six months, aiming three or four drops of lubricant at the end of the conduit. You can't really consider the cable lubricated until you have put in enough to wet the inner surface of the conduit and the outer surface of the cable. How much is that?

If a cable assembly is 4 ft. long, the inner diameter of the conduit is 3/16 in., and the diameter of the cable is 1/8 in., then the total area of all the surfaces on the inside is about 45 square inches, assuming those surfaces are smooth.

They aren't. The cable is made of twisted strands of wire which gives it greater surface area and also nooks and crannies. The conduit is a strip of metal wound in a spiral and also has more area than if it were smooth. The effective area of all the surfaces inside a control cable may be twice as much as it looks, or about 90 square inches.

That's about as big as a page in this magazine.

You can't lubricate that much area with three or four drops of oil. It takes a lot. As a practical matter, if you can see the bottom of a cable, such as the front brake, put oil in the top until it runs out the bottom. For other cables, put in the same amount. It will seem like a bunch.

The cables which lead from the handlebar to nether parts of the machine must, obviously, run downhill. Oil, given the opportunity, will do the same thing. First, it will run down, leaving only a thin film to mark its passing. Then, the thin coating will evaporate. You have to lube oftener than every six months.

The best indicator is the clutch cable. If you educate your left hand to perceive increasing friction, it will tell you when you are due for another lube job. Human senses are generally unreliable because we tend to adapt to circum stances which change gradually, without being aware of the change. When you lube your clutch cable and then notice a big difference in friction, you already waited too long.

Friction, inside the conduit, doesn't really hurt anything inside the conduit. I have never heard of a cable wearing ^^it in the middle from rubbing against WPe outer cover. However, friction in the conduit increases the force required at the control end of the cable and thus hastens failure at the end. Also, friction in the conduit makes your clutch hand tired at the end of a long day and can cause the throttle to stick open.

Nearly any liquid will reduce sliding friction between the cable and the conduit. It is conventional to use petroleum, which, as mentioned, tends to run downhill and dry out. Molybdenum disulphide has some advantages as a cable lubricant. It is a powder and therefore must be mixed with a liquid to get it to penetrate into the conduit. To function simply as a carrier for the moly, it doesn't matter much what the

#uid is.

Moly is very slippery, and if burnished onto a metal surface, it will experience a strong chemical attraction to the metal and greatly reduce friction. Effectively, it will plate the metal and the plating will remain until it is literally worn off. So, a lubricant with moly powder in it is better than one without.

Graphite and Teflon are about as good as moly in terms of reducing friction: however, neither forms a bond with the metal surface. These powders are called solid lubricants and there's not much point, today, in using a cable lube without one of them as an ingredient.

Although it sounds strange to talk about the solid content of a lubricant, it Æk important. The higher the percentage solids (provided they lubricate) the better it is in terms of lubricating control cables.

If you can stretch your imagination to consider a nylon liner as being a lubricant which is 100 percent solid nylon, you get the idea. A nylon-lined cable is better, from a friction standpoint, than metal cable in metal conduit. The manufacturers of nylon-lined cables say you don't need to lube them at all and they do work well that way. I have added moly powder in a liquid carrier to nylon-lined cables and observed a further reduction in friction. However, I also tend to swat the same fly twice and commit other excesses. Lest this sends you rushing out to ^^jy a set of nylon-lined cables for your ^Pooter, you should observe that the lined cable doesn't have any advantage over the unlined except less friction. You can reduce friction in a metal conduit to an acceptable value if you simply keep it lubricated. Personally, I prefer nylon-lined throttle cables because they are pleasant to use and their smoothness allows me to apply magnificent delicacy of throttle control, while smashing into a tree.

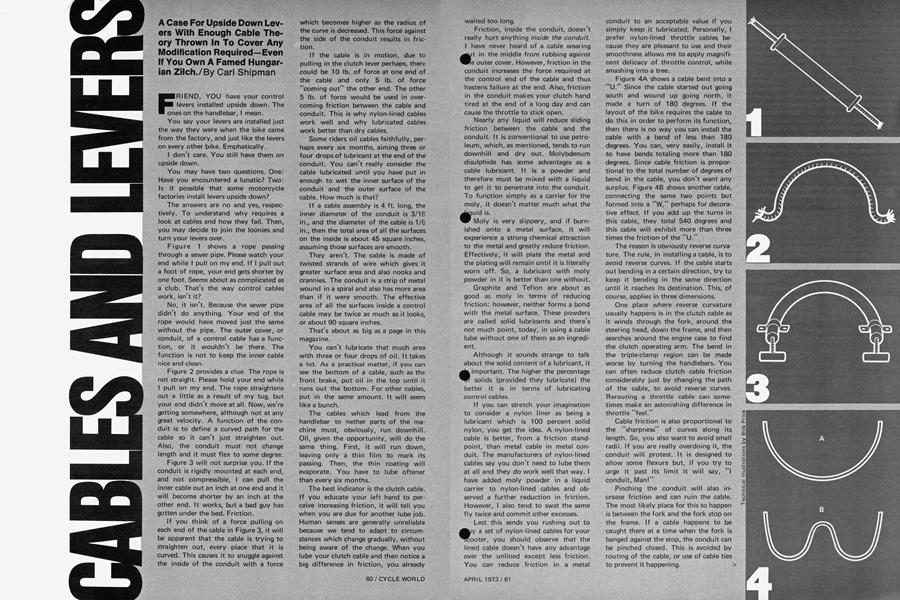

Figure 4A shows a cable bent into a "U." Since the cable started out going south and wound up going north, it made a turn of 180 degrees. If the layout of the bike requires the cable to do this in order to perform its function, then there is no way you can install the cable with a bend of less than 180 degrees. You can, very easily, install it to have bends totaling more than 180 degrees. Since cable friction is proportional to the total number of degrees of bend in the cable, you don't want any surplus. Figure 4B shows another cable, connecting the same two points but formed into a "W," perhaps for decorative effect. If you add up the turns in this cable, they total 540 degrees and this cable will exhibit more than three times the friction of the "U."

The reason is obviously reverse curvature. The rule, in installing a cable, is to avoid reverse curves. If the cable starts out bending in a certain direction, try to keep it bending in the same direction until it reaches its destination. This, of course, applies in three dimensions.

One place where reverse curvature usually happens is in the clutch cable as it winds through the fork, around the steering head, down the frame, and then searches around the engine case to find the clutch operating arm. The bend in the triple-clamp region can be made worse by turning the handlebars. You can often reduce clutch cable friction considerably just by changing the path of the cable, to avoid reverse curves. Rerouting a throttle cable can sometimes make an astonishing difference in throttle "feel."

Cable friction is also proportional to the "sharpness" of curves along its length. So, you also want to avoid small radii. If you are really overdoing it, the conduit will protest. It is designed to allow some flexure but, if you try to urge it past its limit it will say, "I conduit, Man!"

Pinching the conduit will also increase friction and can ruin the cable. The most likely place for this to happen is between the fork and the fork stop on the frame. If a cable happens to be caught there at a time when the fork is banged against the stop, the conduit can be pinched closed. This is avoided by routing of the cable, or use of cable ties to prevent it happening. >

Figure 5 shows a front brake cable attached to the brake lever at the top and the brake arm at the bottom. At the lever, there is a threaded adjuster, which, in function, adds to the length of the conduit. If you screw this adjuster out of its housing, it makes the conduit effectively longer and therefore the inner cable effectively shorter.

There is some distance between the end of the conduit and the place where the cable attaches to the lever. Because this is necessary to attach the cable, we can call it the attachment distance. At the other end is another attachment distance.

Below the lever, in Figure 5, is a sketch showing the position of the lever when it has been "pulled in." This moves the end of the cable by an amount which we can call the working distance. The other end of the cable moves by the same amount since the conduit cannot compress. There are not two working distances. You can think of it as being all at one end, or all at the other, or divided between the two ends.

There may be two threaded adjusters, as shown in the drawing. In installing this cable, it seems like a good idea to have each adjuster set near the middle of its range. The range is not the total length of the threaded part because you always want to have some of the adjuster screwed into its housing. Three-fourths of the threaded length is probably about as much adjustment as you should figure on.

Of course, the control will work with both adjusters screwed all the way in, or both screwed all the way out if necessary, because that is what the adjusters are for.

The adjusters serve three purposes. They take up slack during the original installation and compensate for manufacturing variations. Sometimes, the range of adjustment allows use of a cable that was not intended for the bike it is installed on. After installation, the cable adjuster is used to compensate for gradual stretch of the cable or wear of the element being controlled.

As brake linings wear, it takes longer travel of the operating arm to bring them into contact with the brake drum. To compensate for this, you screw the adjuster out. As clutch plates wear, it takes more slack in the cable to allow them to engage completely. Symptom is, the clutch slips. Cure is to turn the adjuster inward.

In Figure 6, the total length of the inner cable which exceeds the length of the conduit should equal the sum of: one working distance, plus two attach-

ment distances, plus one-half the operating range of the cable adjusters, however many there are. This is true for any cable.

My favorite motorcycle is the fame* Hungarian Zilch which is sold locally by Wild Harvey at his Zilch Motorcycle Parlor. W.H. tries hard but cannot always keep proper cables in stock. So, when I break a cable, I take the pieces in my hand and trot down to see W.H. If he doesn't have the right part-number cable, we scratch around among the cables he does have, to find one that will work.

First, we compare the fittings on the ends. They must be the same, of course. Then, we compare conduit length. An inch shorter or a couple of inches longer doesn't matter. It will still fit on the bike. Then, we pull the inner cable all the way out of one end and compare lengths, keeping in mind that there are one or two adjusters.

We can almost always find som cable that will work on my Zilch, so I don't have to wait for one to be shipped from Hungary. You can do the same thing by taking different cables home, installing them and seeing what happens, but it is a lot simpler to measure first.

Some inner cables have a fitting on the "top" end, but none on the opposite end. A loose fitting is clamped on by a screw and therefore is adjustable for position. With this type, you don't have to replace the conduit. You just pull out the old inner cable and put in a new one that is the same length or a little longer. If you have to use one that is really long, solder around it where you want to cut it off, and then CL through the solder.

Throttle mechanisms also tug on the end of a cable, but in a different way. The fitting on the cable attaches to a drum and the cable is wound up around the drum when the twist grip is rotated, as shown in Figure 7. The other end of the cable attaches to the throttle slide in the carburetor where there is a spring which tends to keep the throttle slide closed. This spring, then, also serves to keep the drum in the throttle mechanism rotated toward the closed position.

The design of twist-grips has to be related to the design of the human wrist.

If you hold your arm up in front of you, close your fist, and move yoi wrist as far as you can in each direction, you will see that the angular travel allowed by your wrist joint is 90 degrees, or a little more. Since it is wrist movement, normally, which rotates the twist grip, this should be taken into account in the design of throttle mechanisms.

If you are dedicated to research, you will also try this experiment with your palm flat and observe that the angular movement of your wrist is greater. Pondering that fact, you will likely conclude that it is useless information because you can't figure out any way to hold onto the handlebar with your palm flat.

If your thirst for research is not quenched, you will try the experiment with your fist partially closed and discover that you can move your wrist more than you can with your fist tightly clenched. This argues for fat twist-grips; however, I don't like them.

If anybody is watching you waggling your wrist and peering intently at it, you will have to provide your own explanation of why you are doing that.

I measured the twist-grip rotation on three bikes by eyeball ing against a protractor. The numbers are approximately as follows: Penton—90 degrees, Cota95 degrees, Husky—110 degrees. These measurements are between the places where the throttle slide bottoms and where the slide hits the top of its travel. If there is slack in the cable, you have to turn the grip to take up slack before it starts pulling up the throttle. A little bit of slack can add 10 degrees to twist-grip rotation. On the Husky, which has some slack, I cannot fully open the throttle with my normal range of wrist movement. I have to either take two "grabs" or move my entire arm to get full throttle.

The cable working distance required by a carburetor is, of course, related to the diameter of the passage where the throttle slide is. A big carb requires more throttle slide travel between closed and open.

At the twist-grip, the working distance is a function of the diameter of the drum and the amount of rotation. Bigger drums wind in more cable for a given rotation.

There are stops in a throttle system, for closed and for open. The important stop, for closed throttle, is normally a screw in the carb which limits how far the throttle slide can move downward. A secondary stop is in the twist grip and regulates how far you can twist it toward "closed." It is normal to adjust the cable so the carb bottoms first and there is a little slack put into the cable as the twist grip continues to rotate over to its stop.

The important stop for full throttle is also in the carburetor. The slide bangs into the roof. The twist grip will normally rotate well beyond this point before reaching its limit of travel. This allows the same twist grip to be used for carburetors of different sizes, requiring more rotation for larger carburetors.

There are special twist grips called "quick throttles" which have a larger drum than normal. Because of the larger drum, it winds in cable faster. Some of these will fully open the throttle slide at a rotation of around 50 degrees. These are used by riders who want to be able to get it on very quickly at some sacrifice in precision of control.

It is desirable for the end-fittings to remain on the ends of the cable, when the control is operated. Otherwise, the rider may become annoyed.

End-fittings are installed in several ways. They may be forcibly pressed on, they may be cast on, or they may be soldered in place. If soldered, it must be done properly, as shown in Figure 8.

The cable is passed through the hole in the fitting and the strands of the cable are then flared out to fit approximately into the taper of the hole. Solder is then flowed in among the strands to fill the voids. The result is that, if you try to pull the cable out of the fitting, the solder must compress. Solder is pretty good in compression, but less so in tension or shear. If the cable end is not frayed out, the only thing that holds it in is the bond between the cable and the solder, which may not be strong enough.

If you buy a cable made like this, check to see that the solder has not run all the way through the fitting and out along the cable on the other side. If solder does this, it makes the part of the cable which has solder on it become very stiff. The cable then cannot bend smoothly over an arc, but tends to bend at a sharp angle right at the end of the solder-stiffened portion. Result is early failure.

Another consideration, which applies to all cables operated by a drum or lever, is shown in Figure 9. The endfitting is held in a hole in the lever or drum. When the control moves, the end-fitting on the cable should rotate easily in the hole. If the control moves through an arc of 45 degrees, the end-fitting should rotate about 45 degrees, with respect to the control.

If it is a tight fit, or is not lubricated, it tends to stick, resulting in a severe bend in the cable, near the fitting. Lubrication and proper clearance solves the problem.

(Continued on page 142)

Continued from page 63

Control cables generally try to tell you about it when they are ill. If the problem is lack of lubrication, the indication is increased force required to operate the control.

When one strand of the cable breaks, it is time to replace the cable because it has begun to fail and complete failure will follow shortly. The broken strand springs away from the cable and may scratch against the housing. If so, you feel this "scratchiness" when you operate the control. Sometimes the broken wire can kink or ball up which can jam a control or limit its travel.

A common problem, particularly with clutch cables, is a symptom which resembles "scratchiness." As you operate the lever, it seems to move in small jerks and it may make a creaking noise. This symptom tells you that the endfitting of the cable is binding in the hole

where it is attached, as shown in Figure" 9. Instead of rotating smoothly in the hole, it is hanging up until the applies force exceeds "sticksion," whereupon it will grudgingly yield a few degrees of rotation and then hang up again.

Lubrication of the cable end-fitting and hole effects a magic cure. However, clutch and brake levers are normally solid on top. The cable end-fitting is inserted into the lever from the bottom.

Some levers are made with the hole extending all the way through the lever, in which case it is convenient to lube from the top. But if the hole is only on the bottom side, you can turn the bike upside down. Or, you can turn the handlebars fully and lean the bike way over. Or, you can disassemble the co trol, put a bunch of lube on the end oi the cable and reinstall, hoping for the best. Whatever you do, it's unhandy and a little frustrating.

The levers are generally symmetrical, except for the hole. The hole is on opposite surfaces of a pair of levers, causing one to be designated "left side" and the other "right side." This is with the holes on the bottom.

If you switch sides, they will fit just as well; however, the holes will be on top. When you lube the cable, you can also lube the end-fitting and the cavity in the lever without trying to get the lube to run uphill. This contributes so much to ease of operation, smoothness and the life of cables, that I have to conclude that the factories put tH. levers on upside down. [§j