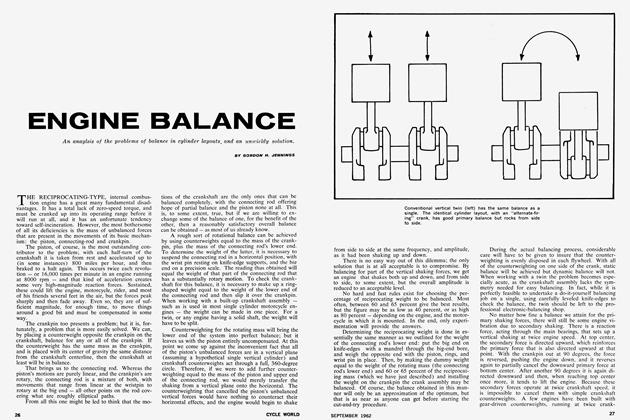

(TECHNICALITIES)

GORDON H. JENNINGS

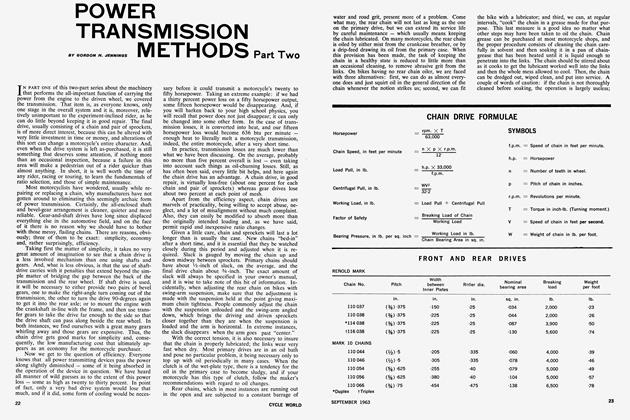

CONSIDERING SOME of the horsepower claims being tossed about these days, it might be a good thing to say a few words about this subject. James Watt, an engineer and inventor (circa 1800), devised the horsepower rating system we use, arbitrarily establishing one horsepower as 33,000 foot-pounds/minute. That is to say, the amount of work represented in lifting a one-pound weight to a height of 33,000 feet in one minute (or 33,000 pounds one foot in one minute, or any other combination of weight, height and time that amounts to the same thing). The above tells us what a "horsepower" is; we no longer lift weights and take time and height measurements - as in the old steam-engine days. Instead, the "dynamometer" is the instrument in use. All dynamometers feed engine output into some form of brake; either water or electrical. This provides a resistance to "load" the engine. This load is measured in a simple and direct fashion. With either an electrical or water brake, the torque being fed into the absorption unit (a more accurate term for the device than "brake") is transferred to its outer casing. A lever, attached to this outer casing, takes the load to a scale, and readings are in pounds. Adding the length of the lever, in feet, gives you a foot-pounds figure, and this is converted to "brake horsepower" by inserting torque and the dynamometer's shaft speed (not alway the same as engine speed) in revolutions per minute into the following formula:

BHP=Torque x RPM/5250

Interestingly, in the formula above we are given the means to determine how much power can be expected from an engine if crank speed is a known factor. It is, of course, also necessary to have a torque figure to plug into the formula, but that presents no very great problem. Torque, you see, is largely a matter of dis placement. A study shows that maximum torque for modern motorcycle engines ranges from 1.0 to 1.2 foot-pounds per cubic inch at the torque peak. At the power peak, the torque figure will be nearer 0.95 to 1.15 ft-lb/in'. In racing en gines, resonant intake and exhaust tuning, with an assist from radical valve timing, will lift the torque peak so near the pow er peak that the two are nearly one, and for racing engines it is not unreasonable to expect a torque output, at the power peak, equal to 1.2 ft-lb/in3. Indeed, in a few highly developed and relatively slow turning racing engines, volumetric effi ciency is maintained at an amazingly high level over the entire usable power range. The Matchless G-50, for example, has a maximum specific torque of 1.31 ft-lb/in and the torque only drops to 1.24 ft-lb/in3 at the engine's power peak. Of course, in these big singles, friction losses are fairly low and such losses would necessarily multiply with high crank speeds or the division of displacement among a greater number of cylinders.

(Continued on page 16)

There is great encouragement in the above figures for anyone who would like to put some time into the development of a road racing Ducati. With the right combination of ports, pipes, valves and valve timing, it should be possible to get very near that 1.24 ft-lb/in3 specific torque figure at 10,000 rpm. From our horsepower formula, we can see that this would yield some 35 bhp, which would make the Ducati quite competitive in our AMA races. In this connection, it is interesting to note that if one follows Ducati's recommendations with regard to "redline" and uses only 8500 rpm, power output is automatically restricted to 30 bhp — and that would only be attainable with a megaphone.

Actually, in touring-type engines, torque at the power peak will be more in the order of 1.0 ft-lb/in% as was noted earlier. And even that level of output would be characteristic of the relatively high output touring engines. The need for smooth low-speed running prevents anything resembling super-tuning.

Should you wonder about some particular horsepower claim, the information presented here can be used to shed a bit of light on the question. There is still room for a little fudging, but you will be able to arrive at a fairly accurate probability.

You might note that peaking speed plays a large part in these horsepower predictions. And, that is largely the way things work out in practice. Unless supercharging or oxygen-bearing fuels enter the picture, horsepower will always (assuming good breathing) be the product of displacement and engine speed. Boost an engine's peaking speed, and you boost its power output. Without increasing crank speed, there will usually be only very small gains in horsepower.

At least, that is true of 4-stroke engines. The 2-stroke is a different proposition. Because the 2-stroke engine employs every "downward" stroke of the piston as a firing, or power stroke, it offers the tuner a chance (a very slender chance) of doubling the power of a 4stroke engine. Thus, if we assume that good design work and resonant tuning will give a 4-stroke engine a specific torque output of 1.24 ft-lb/in3 at the power peak, then the 2-stroke, if it would operate at the same level of volumetric efficiency, would give us 2.48 ft-lb/in'. That, in turn, would produce a 60 bhp two-stroke at the same displacement and crank speed as a 30 bhp 4-stroke.

Fortunately, for the balance of the racing world, the matter is not that simple. The 2-stroke, in any known form, will not begin to equal the volumetric efficiency of the 4-stroke. It is competitive because it delivers a power stroke twice as often. Of course, as 2-stroke development continues, the "ring-ding's" breathing will continue to improve, and may even get almost level with the 4-strokes.

(Continued on page 18)

That will not upset the balance. It appears that the point of diminishing returns in volumetric efficiency is reached when the 2-stroke gets up around 14,000 rpm. Four-stroke engines on the other hand can be made to breath very well even at 20,000 rpm and beyond. So, for the present, we have what appears to be a horsepower stalemate, with development work in 2-stroke engines progressing along the lines of improving volumetric efficiency without any significant rise in crank speed; and 4-stroke development directed toward increased crank speed while retaining the existing, excellent, level of volumetric efficiency. Work seems to be moving along at about the same rate for both camps; no one could predict, with any accuracy, which will emerge dominant — or if either one will, in fact, ever gain a substantial advantage over the other.

With all the fiberglass being used in such motorcycle parts as seats, fuel tanks, fairings and fenders, it is interesting to consider the possibility that we might be able to use fiberglass in a motorcycle's "frame." There is a precedent. One of the most successful of modern sports/racing cars, Jim Hall's Chevrolet-powered "Chaparral," has a load-carrying unitized body/ chassis of fiberglass. This would seem to prove that fiberglass construction is feasible; stresses for a racing car — especially one being propelled by a large, heavy V-8 engine — are vastly greater than those applied to the frame of a racing motorcycle.

A bit of preliminary sketching tells me that fiberglass construction could be used without departing from conventional appearance. There are already motorcycles in production with virtually solid fiberglass paneling from steering-head to swing-arm pivot to rear fender. Why not make the tank, seat, rear fender and the side panels enclosing the air-cleaner all a single, load-carrying piece? Added layers of fiberglass cloth can be laminated in at the areas of stress concentration, and tabs welded to the steering crown, swing-arm pivot and rear suspension mounting lugs would spread the loads around and prevent local overloads. The same sort of techniques, already developed and prooftested in automotive and aircraft applications, would be applied to engine/transmission mounting lugs. For a scrambler, it might be wise to use a pair of tubes to cradle the engine, in the conventional manner, as this would provide a good mounting for the "bash" plate. And, for the road racers, it should be possible to incorporate part or all of the fairing into the load-carrying structure.

It cannot be expected that this type construction would ever become very popular for mass-produced motorcycles. Quantity production would lead to replacing the fiberglass with steel — even though the design work might be similar in all other respects. However, for lowvolume production of racing or sports/ racing motorcycles, scramblers and road racers, unitized fiberglass might provide a weight and cost advantage.