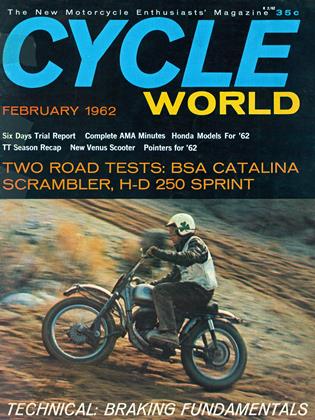

BRAKING FUNDAMENTALS

GORDON H. JENNINGS

HUMAN NATURE being what it is, it was probably inevitable that “go” should receive more attention than “stop” in the development of the motorcycle. Indeed, if we consider how minor a sales point is good braking, compared with the qualities of acceleration and speed, it is a real tribute to the public-spirited outlook of the manufacturers that the brakes on the modern motorcycle work as well as they do. Good brakes are, after all, not all that easy to provide — as we shall presently see.

It is the function of any braking device to slow the speed of the vehicle to which it is attached. That sounds like a perfectly obvious thing to say, and a simple condition to meet — and yet, right from the beginning, the problem gets increasingly involved. First off, we are faced with the fact that a motorcycle and rider, with a combined weight of perhaps 600 or more pounds and traveling at a good rate of speed, represents a tremendous amount of kinetic energy. This must somehow be removed before the mass can be brought to a halt. In a conventional brake system, this energy is converted into heat — the actual transformation being accomplished by the friction surfaces in the brake unit.

Oddly enough, there are other braking devices that do not use this familiar method. Everyone is aware that most military aircraft have “dive-brakes”, which consist of panels that the pilot can extend out into the airstream and which are actually very effective in slowing the plane. In the case of the dive-brake, the energy is converted mostly into heat, too, from the friction of air against the brake panel and in the air-turbulence created. No one has, as yet, made a serious attempt to use such a device on a motorcycle but the technique used by racing riders, of sitting up abruptly when braking hard from high speeds, is essentially the same thing. Here, the rider’s torso serves as an air-brake and it can be a very effective one \^hen speeds of 90-100 mph are involved. It should be appreciated, however, that this is only effective at high speeds and that anyone relying on such an expedient at touring speeds may have some exciting moments.

With such simple, if slightly unsatisfactory, methods of stopping the motorcycle denied him, the designer will have to utilize the more conventional system where the retarding force is applied to the rotation of the wheels and tires. Quite obviously, if we stop the rotation of the tire, the motorcycle will come to a halt. But, as it goes almost without saying, there is more to the problem than just that. Even if it were possible to lock the wheels without losing control of the bike, this solution would be far from satisfactory. We still must cope with the enormous kinetic energy of a fast-moving bike and rider and this energy — converted into heat by the rubbing of the tire against the ground — would completely destroy the tire after a very few stops. Rubber is not, unfortunately, too well suited to withstand the effects of high temperatures. It has a distressing tendency to burst into flame when subjected to a lot of heat. And, even if outright burning could be avoided, tire wear would be intolerably rapid and a motorcycle equipped with locking brakes would take an uncomfortably long time to stop. The coefficient of friction for a sliding tire is only a fraction of that of a tire that is still rolling — even though the letter may be under a very heavy braking load and also just about to lock. Therefore, because of these fundamental considerations, the braking device will have to deal with the bike’s kinetic energy alone. More importaht, it will have to do the job many hundreds of times without a perceptible loss of efficiency if it is to be considered practical, and that is — as it happens — a pretty good trick.

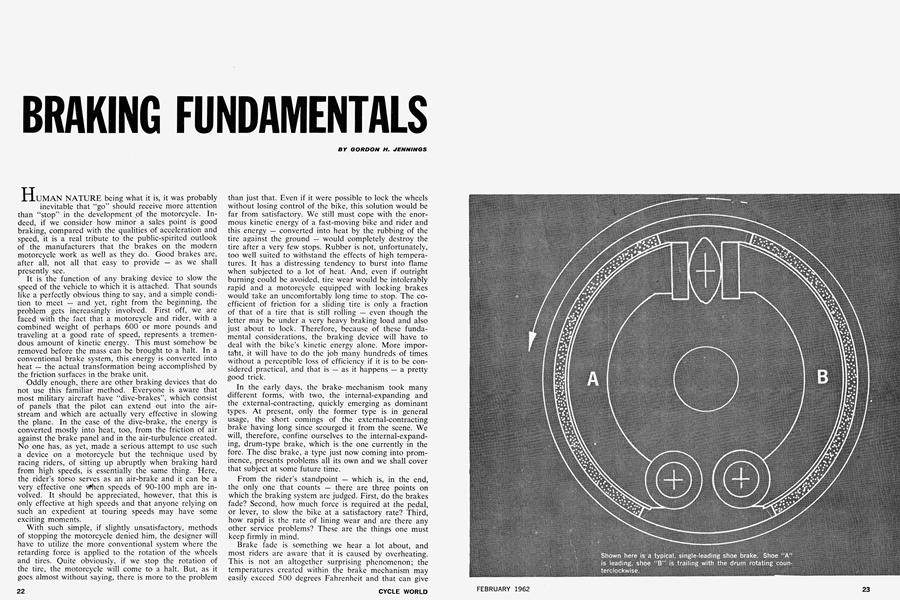

In the early days, the brakemechanism took many different forms, with two, the internal-expanding and the external-contracting, quickly emerging as dominant types. At present, only the former type is in general usage, the short comings of the external-contracting brake having long since scourged it from the scene. We will, therefore, confine ourselves to the internal-expanding, drum-type brake, which is the one currently in the fore. The disc brake, a type just now coming into prominence, presents problems all its own and we shall cover that subject at some future time.

From the rider's standpoint — which is, in the end, the only one that counts — there are three points on which the braking system are judged. First, do the brakes fade? Second, how much force is required at the pedal, or lever, to slow the bike at a satisfactory rate? Third, how rapid is the rate of lining wear and are there any other service problems? These are the things one must keep firmly in mind.

Brake fade is something we hear a lot about, and most riders are aware that it is caused by overheating. This is not an altogether surprising phenomenon; the temperatures created within the brake mechanism may easily exceed 500 degrees Fahrenheit and that can give rise to all sorts of problems. For instance, the brake drum, against which the brake shoes must make contact, tends to change both diameter and shape at the very high temperatures mentioned. In its most simple form, this kind of fade can be caused by the brake drum’s “growth” at elevated temperatures. Like all things, the drum expands with rising temperatures and if the rate of expansion for the drum and the brake shoe is different, their respective radii may become so dissimilar that only a small area in the center, or at each end, of the shoe would contact the drum. From this, it may be seen that there are definite pitfalls in the use of aluminum-alloy brake drums and steel shoes — or vice versa.

The difficulties created by tíigh temperatures on the brake drum do not end there. Only an absolutely symmetrical casting or forging, with complete uniformity of alloying elements and molecular structure, would expand evenly, and the brake drum is none of those things. Except in rare instances, the drum does not even approach symmetry. It takes the form of a cylindrical ring, with a web on one side to attach it to the hub and an outward-turned flange on the other side where the spokes are laced in. When the brakes are applied, the heat is created only at the ring portion and the temperatures throughout the drum are very uneven. They are usually highest at the outer edge of the ring and this expands more than the area next to the web, with the natural result that the drum begins to lose its cylindrical form. Instead, it assumes a slightly conical shape and the shoes make contact only along one edge. In practice, the problem is even more complicated. Minor imperfections that are unavoidable in even the most painstaking of manufacturing operations cause localized warping of the drum and the temperatures at these “hot spots” may reach 1000°F. or more.

Brake drums may be made of pressed, low-carbon steel and this type is very popular with cost-conscious manufacturers as it is by far the cheapest to make. Unfortunately, the pressed-steel drum may try to return to its original, flat-sheet form when heated by hard braking. Also, it does not wear very well and is decidedly inferior to the forged, high-carbon steel drum, which is very strong, dimensionally-stable and can be made to resist scoring and too-rapid wear by the addition of manganese, nickel and chromium as alloying elements. Cast nickel-chromium iron is also very good; not as strong as a forging, but better in other respects. The best type of all is, of course, the Al-fin drum, which is of aluminum alloy with a cast-in iron liner. It is light, rigid, and gives a very high rate of heat dissipation.

This last factor is very important. Unless the heat generated by braking can be removed, the temperature would rise with each successive application of the brakes until the entire mechanism failed. Naturally, it is possible to destroy even the best of brakes by continuous application, but within the range of normal use, or even in racing, there is enough time between applications for recovery. Obviously, a finned aluminum drum will cool faster than one of iron and that is why they are used — especially in racing, where their higher cost is not such a deterrent. Finning on an iron drum is largely wasted. Heat flow through iron is so slow that the inside of the drum can be frying while the outside is still relatively cool. Therefore, fins on an iron drum will just make the outside cooler without helping the inside perceptibly. As a matter of fact, even the fins on an aluminum drum are of limited immediate usefulness when braking. More important, at the time braking is actually occurring, is the existence of a fairly large mass of aluminum, which can absorb the heat as it is generated. This “heat sink”, as it is called, removes and stores the heat until the slower process of transfer to the air can take place.

From all this, it may be seen that brake fade, which is often thought to originate in the lining material, is actually a function of drum-shortcomings. There may b« specific instances where the linings are at fault, but this will always be due to extraneous factors — such as a toosoft lining used because the whole brake is handicapped by a cheap, pressed drum. This should not be allowed to obscure the basic fact that there are lining materials available, today, that will not fade. The best known example of such linings are those brutal sintered-metal blocks used to overcome the basic braking shortcomings of certain automobiles. With these metal linings, the

This necessity for balance is also true when we consider the basic brake-shoe layout. In the conventional motorcycle brake mechanism, there are two shoes, and these are pivoted on one side of the backing plate and the actuating force is applied at the opposite side — usually by means of a two-lobe cam interposed between the free ends of the shoes. In this layout, one of the shoes is pulled against the drum in a sort of self-actuating effect, due to the offset between the shoe-pivot and the drum. It is, essentially, a wedging action and the greater the offset, the greater the self-energizing effect. The wedging shoe is commonly referred to as a “leading shoe,” and the other a “trailing shoe.”

It should occur to most of you at this point that a brake system in which both shoes are leading will have a strong self-energizing action and will require a minimum of muscle from the rider. That is, of course, absolutely true. Unfortunately, the two-leading shoe arrangement is very sensitive to changes in friction coefficient at the lining. Therefore, a combination of drumsize, lining-hardness and self-energizing action that gives smooth stopping when cool may fade drastically with a very small rise in temperature. Or, if a “sticky” lining is fitted, the brake may develop a tendency to grab and lock when used hard.

A double-trailing shoe system will require more strength from the rider than most are willing to supply, but it has one great virtue: it is all but completely insensitive to changes in lining-friction. The type has been seen in action only a very few times, and usually only when stable braking action has not been attainable through more orthodox methods. And, in almost every instance, it has been necessary to include some sort of power-booster in the braking system.

The one-leading, one trailing shoe arrangement that is almost universally used on motorcycles nearly always has a fixed expander-cam. This means that very little self energizing effect will, in fact occur — even though the design does have one leading shoe. The reason is simple; any wedging effect will result in the leading shoe moving away from the actuating cam, and that automatically regulates the pressure. The trailing shoe, which tends to move away from the drum, is trapped by the cam and cannot, so the two shoes, in the end, are always being applied with substantially the same force. The sole failing of this type is that it will necessarily require more effort from the rider than either the “true” one-leading, one-trailing shoe system. This shortcoming is sometimes overcome by making either the shoe anchors or actuating cam “floating”, which allows the shoes to assume their proper functions, leading and trailing. Such a solution to the problem is not without complications, however, for a true leading-shoe will show about three times as much lining wear as the onp in the trailing position. Then, unless a different grade of lining material is specified for each of the shoes, uneven wear will create something of a service problem.

The best solution, where cost considerations will permit, is probably to accept the deficiencies of the twoleading shoe system and use it anyway. If lining of sufficient hardness is selected, and the shoe pivots are positioned for a minimum of self-energizing action, the problems of fade and/or sticking can be largely overcome. Of course, some of the lightness of action that is the chief attraction of the two-leading shoe system will be lost, but if care is taken, this can be the best of the entire lot. The only real problem is one of cost and sometimes the results obtainable with one of the other, less expensive, types of systems are so good that any improvement — however attractive on theoretical grounds — would be superfluous. For that reason, if your particular bike’s brakes do not happen to match the highest standards set forth in this article, do not get upset. There may be some very good underlying reasons for the form they have.

Taking all factors into consideration, the best way to get outstanding brake performance is simply to use a very large unit. A large aluminum drum is not likely to reach the point of thermal-overload except under the most extreme conditions. Further, the sheer size of the brake components found inside that big drum more or less preclude any possibility of rapid lining wear or other service problems. Here again, though, the obvious and easy answer carries penalties.

From the standpoint of overall motorcycle performance, oversize drums cause all manner of problems. The mass involved is all carried at the wheel and must move up and down with it. which raises the total unsprung weight and makes it much harder for the springs and shocks to hold the wheels against the ground. The seriousness of this side of the question should not be underestimated — particularly in connection with very light racing machines.

A more common reason for using some type of brake other than the ideal is, obviously, cost — which may be many times higher for a fairly modest increase in efficiency. Under normal touring conditions, the performance of the very best brake is not all that much better than the worst.

brake can almost glow red before they fail — which they ultimately do, of course. Some hope exists though. Recent developments have made the sintered-metal lining more kind to the drum, not so abrasive, and they may yet prove useful in normal, touring applications.

Present brake linings are asbestos-based. Early in the game, asbestos was chosen for its excellent heat-resistant and frictional properties and no one has, as yet, found anything much better. Pure asbestos however, is none-too strong, and some kind of bonding material is needed to keep it from disintegrating in service. Rubber bonding has been used, as have various asphaltic compounds, but the former’s coefficient of friction falls to almost nothing when wet and the latter tends to get sticky if the brakes are over-used and get hot. The best bonding agent is probably synthetic, thermo-setting resin, which is widely used today. Resin-bonded linings are cheap, and have the attractive property of giving a reasonably constant coefficient of friction through the temperature range normally encountered.

Generally speaking, although it is dangerous to apply generalities to anything as complex as the motorcycle brake, a lining that gives a high coefficient of friction initially will tend to become erratic with increases in temperature. Conversely, a “hard” lining, which has a relatively low coefficient of friction, will perform in a more uniform manner over a broad range of temperatures. This being the case, it would seem that the hard lining would always be the better choice — and indeed it often is — but there are overriding factors. Hard linings, with their low coefficient of friction, require much more pressure (against the inside of the drum) to develop any given level of retarding force than do soft linings. As a result, lining selection is always something of a compromise, where the designer tries to achieve some measure of balance between fade-resL tance and pressure requirements.

Ideally, a braking device would not just convert the kinetic-energy represented by the bike and rider into useless heat and then throw it away. If the energy could be stored for use when the rider was again ready to accelerate and then released at that time, how much greater would the motorcycle’s overall efficiency be.

Perhaps, when missile age technology has improved the efficiency of electrical hardware sufficiently, it will be possible to do something about this. If we'could have high-output generators at the wheels instead of brakes, these could, be switched on when the rider wantecj to stop and the power absorbed in turning the generators would do the trick. The power thus generated could be stored in batteries and switched back to the generators — which will serve very nicely as motors, too — to accelerate back up to speed. Fanciful? Indeed it is, but it could happen and probably ultimately will.

For the present, however, we are going to find that there is a lot of mileage left in the ordinary drum-type brake. The subject is very complex — we have just scratched the surface here — but there is still a lot of room for improvements to keep pace with rising speed. There is certainly a lot more to the subject than we have dealt with here, but one must start with the fundamentals, and we have tried to cover those here. At another time, perhaps we can get more specific.

View Full Issue

View Full Issue

More From This Issue

-

Cycle Round Up

February 1962 -

The Service Department

February 1962 By Gordon H. Jennings -

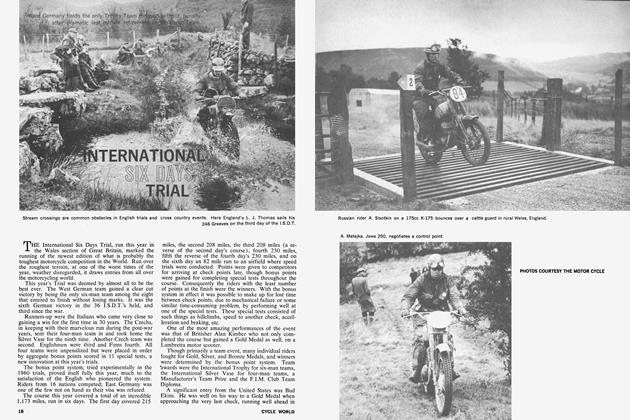

International Six Days Trial

February 1962 -

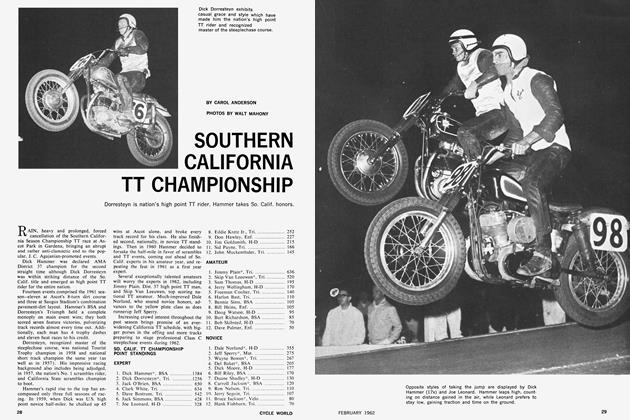

Southern California Tt Championship

February 1962 By Carol Anderson -

Complete Minutes of the Annual Ama Technical Committee Meeting

February 1962 -

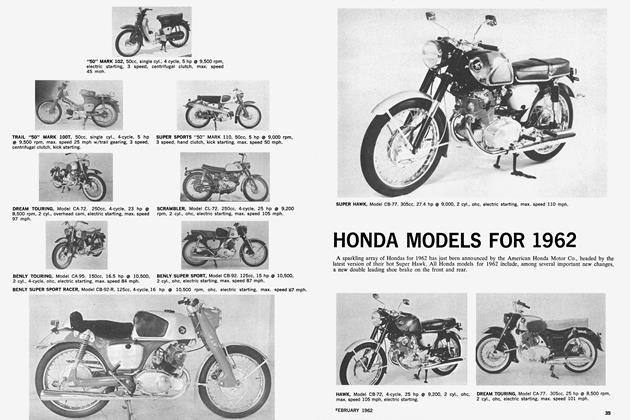

Honda Models For 1962

February 1962