Myth Of The Full-Floating Brake

What’s It All About, Alfie?

J. G. Krol

A FLOATING REAR brake is supposed to cure hopitis...that dread chassis disease in which a touch on the brake pedal sets the tail of the bike to hopping, lurching through the air, and trying its best to beat the front end down a hill into the jaws of the angry rocks below. Does a floating brake really help, and if so, how? Or is this just another of those misleading myths that mire motorcycles in a miasma of mechanical mediocrity?

The usual rationale for a floating brake is that it decouples suspension movements and brake actuation. Applying the brake does not tend to lock-up the suspension, or prevent it from following the bumps, ruts, and whoops. Conversely, movements of the rear suspension do not tend to change the degree of braking effort.

However, two of the three most common types of brake-actuating systems are hydraulically operated and cable operated brakes. In both cases braking effort is independent of suspension motion to start with, and if we accept the usual argument at face value, a floating brake is entirely redundant.

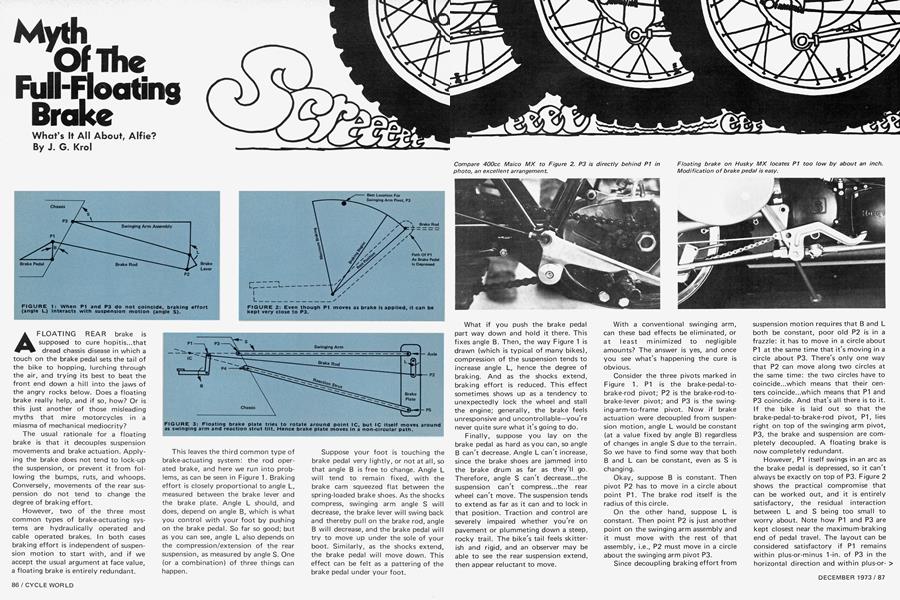

This leaves the third common type of brake-actuating system: the rod operated brake, and here we run into problems, as can be seen in Figure 1. Braking effort is closely proportional to angle L, measured between the brake lever and the brake plate. Angle L should, and does, depend on angle B, which is what you control with your foot by pushing on the brake pedal. So far so good; but as you can see, angle L also depends on the compression/extension of the rear suspension, as measured by angle S. One (or a combination) of three things can happen.

Suppose your foot is touching the brake pedal very lightly, or not at all, so that angle B is free to change. Angle L will tend to remain fixed, with the brake cam squeezed flat between the spring-loaded brake shoes. As the shocks compress, swinging arm angle S will decrease, the brake lever will swing back and thereby pull on the brake rod, angle B will decrease, and the brake pedal will try to move up under the sole of your boot. Similarly, as the shocks extend, the brake pedal will move down. This effect can be felt as a pattering of the brake pedal under your foot.

What if you push the brake pedal part way down and hold it there. This fixes angle B. Then, the way Figure 1 is drawn (which is typical of many bikes), compression of the suspension tends to increase angle L, hence the degree of braking. And as the shocks extend, braking effort is reduced. This effect sometimes shows up as a tendency to unexpectedly lock the wheel and stall the engine; generally, the brake feels unresponsive and uncontrollable—you're never quite sure what it's going to do.

Finally, suppose you lay on the brake pedal as hard as you can, so angle B can't decrease. Angle L can't increase, since the brake shoes are jammed into the brake drum as far as they'll go. Therefore, angle S can't decrease...the suspension can't compress...the rear wheel can't move. The suspension tends to extend as far as it can and to lock in that position. Traction and control are severely impaired whether you're on pavement or plummeting down a steep, rocky trail. The bike's tail feels skitterish and rigid, and an observer may be able to see the rear suspension extend, then appear reluctant to move.

With a conventional swinging arm, can these bad effects be eliminated, or at least minimized to negligible amounts? The answer is yes, and once you see what's happening the cure is obvious.

Consider the three pivots marked in Figure 1. P1 is the brake-pedal-tobrake-rod pivot; P2 is the brake-rod-tobrake-lever pivot; and P3 is the swinging-arm-to-frame pivot. Now if brake actuation were decoupled from suspension motion, angle L would be constant (at a value fixed by angle B) regardless of changes in angle S due to the terrain. So we have to find some way that both B and L can be constant, even as S is changing.

Okay, suppose B is constant. Then pivot P2 has to move in a circle about point P1. The brake rod itself is the radius of this circle.

On the other hand, suppose L is constant. Then point P2 is just another point on the swinging arm assembly and it must move with the rest of that assembly, i.e., P2 must move in a circle about the swinging arm pivot P3.

Since decoupling braking effort from suspension motion requires that B and L both be constant, poor old P2 is in a frazzle: it has to move in a circle about P1 at the same time that it's moving in a circle about P3. There's only one way that P2 can move along two circles at the same time: the two circles have to coincide...which means that their centers coincide...which means that P1 and P3 coincide. And that's all there is to it.

If the bike is laid out so that the brake-pedal-to-brake-rod pivot, P1, lies right on top of the swinging arm pivot, P3, the brake and suspension are completely decoupled. A floating brake is now completely redundant.

However, P1 itself swings in an arc as the brake pedal is depressed, so it can't always be exactly on top of P3. Figure 2 shows the practical compromise that can be worked out, and it is entirely satisfactory, the residual interaction between L and S being too small to worry about. Note how P1 and P3 are kept closest near the maximum-braking end of pedal travel. The layout can be considered satisfactory if P1 remains within plus-or-minus 1-in. of P3 in the horizontal direction and within plus-orminus !4-in. of P3 in the vertical direction, not counting the free-play before braking begins. If the designer is at all serious about decoupling braking effort and suspension motion, he can cut these distances in half.

As a rule of thumb, a unit of vertical offset between P1 and P3 generates more braking-suspension interaction than a like amount of horizontal offset. The arrangement of Figure 2 works out very nicely in this regard since Pi's up-and-down movement is much smaller than its back-and-forth movement.

This leads to the suspicion that the brake linkage is normally one of the last parts of a bike to be "designed"—which means that it's just sort of bolted on wherever it'll fit the easiest. You can check your own scooter easy enough, and that's what you'll have to do because there are no clear consistencies among brands, models, or years in the proximity of P1 and P3. Sometimes a hacksaw and welding job can be done on the output arm of the brake pedal to get P1 closer to the swinging arm pivot, thereby reducing braking-suspension interactions, at least to a degree. If such surgery is possible on your bike, it's well worth doing and infinitely more costeffective than a pair of trick shocks that can at best mask the symptoms of wheel hop instead of attacking the problem at its source.

We conclude that there is nothing mysterious, or terribly difficult, about designing a conventional rod-operated brake linkage so that braking effort and suspension movements are almost completely decoupled: merely locate the brake-pedal-to-brake-rod pivot as close as possible to the swinging arm pivot, especially in the vertical direction. Is it possible to do any better with a floating brake?

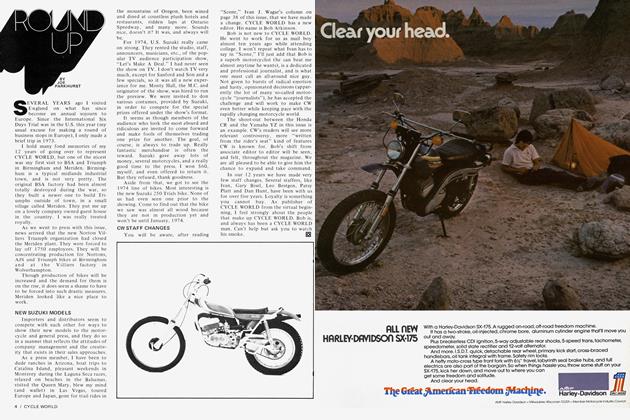

A typical floating brake assembly is shown in Figure 3, where P1, P2 and P3 are the same as before, but there are three new points of interest to consider: P4 and P5 are the pivots of the reaction strut at its frame and wheel ends, respectively; also, the axle itself functions as a pivot. The suspension is now composed of four "bars," viz., the frame, the swinging arm, the brake plate, and the reaction strut. How does this complicated mechanism function?

To decouple braking effort and suspension motions we still have to arrange the geometry so that P2's brake-roddetermined path (a circle about P1) is identical to its suspension-determinedpath (with angle L fixed as angle S changes); this is a perfectly general requirement that applies to all kinds of suspensions. The first problem is to figure out just what P2's suspensiondetermined path is.

First you need to locate the "instant center" of the brake plate (and hence of P2). This is done by extending a line through the axle and P3 until it intersects with a line extended through P4 and P5; this intersection defines the instant center, identified as point IC in Figure 3. At each instant, P2 moves as if it were turning in a circle about IC. But when P2 actually does move, so do the swinging arm and reaction strut, which tilt to new positions and determine, therefore, a new location for point IC. If IC were a fixed point, P2 would merely turn a circle about that point. Actually, P2 is trying to turn a circle about a point that itself is moving around.

The less that 1C moves, the closer to a circle is P2's suspension-determinedpath. The more that 1C moves, the more non-circular P2's path becomes. Everything depends on the proportions of the four-bar linkage. For example, if P2 is located very close to the axle, its actual path will be very close to that of the axle—which is simply a circle about P3. And if P2 is located very close to the end of the reaction strut, its actual path will be very close to that of P5—which is simply a circle about P4. In the former case, you'd want P1 close to P3; in the latter case, you'd want P1 close to P4. If P1 is part way between the axle and P5 (vertically) you'd expect to find P1 part way between P3 and P4 (vertically).

All of this leads to two striking conclusions about floating rear brakes. In the first place, there is absolutely nothing about the floating brake concept in itself that makes is automatically superior to a conventional brake. A floating brake, just like a conventional brake, can be laid out so that it provides negligibly small, or intolerably large, interactions between brake actuation and suspension movements. Everything depends on the geometry of a given motorcycle. Floaters, just like sinkers, can be well designed or badly designed. It is basically wrong to assume that one of these arrangements is inherently superior to the other.

In the second place, there is no way for any floater to be significantly better in decoupling braking effort from suspension motion than a properly designed sinker. Bikes like the Maico 400 and the Triumph Twins look just like Figure 2, which is the best that can be done in practice and which is perfectly adequate. No floating brake mechanism, no matter how carefully designed, could do substantially better.

So why mess with floating brakes at all? The basic answer is that what we have been accustomed to thinking of as a kind of brake is actually a kind of suspension. I, at least, was badly misled by an unfortunate choice of terminology. Until I sat down to draw a careful representation of the geometry of brake actuation systems, I took for granted that floating brakes decoupled braking effort from suspension motion. After all, "everybody knows" that that's what floating brakes are for.

Instead of using the term "floating brake"—which implies that we're talking about a particular kind of brake—we should adopt the terminology of automotive engineers and call this same design concept a "twin trailing arm suspension," or TTA suspension.

Here's what's involved. When a bike brakes or accelerates, the chassis moves on the suspension. How much it moves, and in which direction, depends on the kind of suspension. For example, applying the front brake causes the front suspension to compress if it's a telescopic fork, but to extend if it's a leading-link fork. Similarly, the rear suspension, depending on its design, may extend, compress, or ride level in response to different combinations of front-braking, rear-braking, and throttle-opening. Naturally, the designer is faced with compromises on all sides. The more design parameters he has to play with—assuming he knows what he's doing—the better overall compromise he can achieve.

The TTA suspension provides more design parameters to achieve an allaround optimum compromise, as can be convincingly demonstrated by considering two special cases of the TTA suspension.

Keeping P5 some distance below the axle, let's move P4 closer and closer to P3. As this happens, 1C moves closer to P3. In the limiting case, the reaction strut is anchored to the frame at a point that coincides with the swinging arm pivot; then P3, P4, and 1C merge into a single point. In this case, the TTA suspension behaves exactly like a conventional swinging arm.

Alternately, keeping P4 some distance below P3, let's move P5 closer and closer to the axle. In the limiting case, P5 coincides with the axle; then the axle is mounted on a triangle consisting of the frame, the swinging arm, and the reaction strut and this triangle, of course, cannot move. In this case, the TTA suspension behaves exactly like a rigid rear end.

Many motorcyclists would subscribe to these statements: (1) a rigid read end is completely different from a swinging arm suspension. (2) the old-fashioned "spring-hub” and "plunger" type rear suspensions are sort of part way between a hard-tail and a swinging arm. (3) a "floating brake" is mainly a kind of brake, and has no significant connection with the kind of suspension. Actually, all three notions are false.

First, the hard-tail and the conventional swinging arm are each merely special cases of the TTA suspension, each arrived at by varying the proportions of a TTA suspension. Second, the "spring-hub" and "plunger" suspensions, with their straight-line sliding motions, are the approaches that are completely alien to the TTA concept. And third, the "floating brake" is actually the kind of suspension that lies midway between a swinging arm and a hard-tail.

Furthermore, if you think of the swinging arm as that special case of TTA suspension obtained by moving P4 all the way to P3, it becomes obvious that many of today's "floating brakes" function so similarly to plain swinging arms that the main reason for their existence must be to give the motorcycle salesman something to point at with pride. When the angle between the swinging arm and the reaction strut and the relative location of P3 and P4 are such that the instant center lies very close to the swinging arm pivot—and moves around very little as the suspension compresses and extends—the whole business works almost like a simple swinging arm and sinking brake. So why bother?

When you're examining a bike there are two simple visual checks you can make. First, visualize the line of the swinging arm (defined by P3 and the axle) and the line of the reaction strut (defined by points P4 and P5). Observe where these two lines intersect; that's the instant center. If the IC lies very close to the swinging arm pivot, and remains close for all movements of the suspension, the “floating brake'' behaves very much like a conventional brake and swinging arm. Hence, there is every reason to suppose that it exists merely as a marketing gimmick. At the other extreme, if P5 were below the axle and P4 were above the swinging arm pivot, the IC would lie where the swinging arm and reaction strut crossed in side view, and the suspension would behave quite differently from a conventional one.

Second, observe the proximity of P1 to the instant center, remembering that for a conventional swinging arm the instant center lies at the swinging arm pivot itself. The closer, the better, especially in the vertical direction. The farther P1 is from IC, the worse will be the interaction between brake actuation and suspension motion.

Does anybody know who coined the term, "floating rear brake?" Whoever it was, his intentions were no doubt the best, but his choice of terminology was disasterously bad, for it has created tremendous confusion, much misdirected concern, and a whole bunch of misplaced effort. When we're talking about a suspension that has two trailing arms it would make much more sense to call it something like a twin trailing arm suspension—and doing that would avoid many misleading connotations.

In recent years "floating brakes" have become a roaring fad. But no "floating brake" ever made works better as a brake than a properly designed conventional system, per Figure 2. Indeed, if the rear brake is hydraulically operated or cable operated it cannot be improved as a kind of brake by the addition of a reaction strut from the brake plate to the frame. The real problem in brake actuation is that so many conventional brakes are so badly designed, with P1 so far from P3.

Someday all bikes with conventional swinging arms and rod operated rear brakes will have P1 and P3 as close together as on a few current Triumphs, Montesas and Maicos, and the "Myth of the Floating Brake" will be interred, a chrome-moly stake through its heart, in the infield of Ontario Motor Speedway, resting peacefully between Heavy-CarsHold-the-Road-Better and Long-StrokeE n g i nes-Have-More-T orque, disturbed only by the Instamatic-clicking of funny-hatted tourists chattering nervously among themselves about how scary it must have been way back there in the Twentieth Century when such fearsome myths prowled the land unchecked. Maybe it could even happen sooner. I hope so, for right now is not too soon to torpedo the "Myth of the Floating Brake."

View Full Issue

View Full Issue