CONTROLLED FILL

ELEMENTS

Efficient metal casting in the 21st century

KEVIN CAMERON

Metal casting, the process of creating desired shapes by pouring liquid metal into molds and letting it solidify there, has been practiced by our species for some 7,000 years. For most of that time casting was solely the product of practical experience. Only in the last hundred years or so has it assumed a more scientific character. Some 25 years ago I asked former Battle of the Twins builder John Wittner how he and others then working at Guzzi determined the proper minimum thicknesses of castings.

“We didn’t,” was his reply. “That was up to the old-timers in the foundry.”

To get an idea what has been accomplished in casting technology since 2000, we can compare the weights of 1,000cc engines of the 1 970s with that of Ducati’s present production V-4s. The giant air-cooled engines of the sit-up Superbike era came across the scales at 200-225 pounds. But that has dwindled to the 142 pounds of the V-4, a one-third reduction in weight, while horsepower has risen 2-1/2 times, from the 85 of long ago to over 200 hp today.

When Yamaha introduced aluminum chassis to GP roadracing in 1980, the light metal soon morphed into complex steering-head and swingarm uprights CNC machined-from-solid, then welded to press-formed or extruded main beams. The result was ultralight and stunningly beautiful—those lovely welds!—but impossible for production motorcycles because of its intensive use of time, materials, and special skills.

What was needed was a “net shape” manufacturing process that could deliver the desired shape without tying up costly prototype machining facilities, without requiring 20 or more feet of time consuming welds, and without most of the material used being wasted as scrap.

Meanwhile, Keith Duckworth was confronting a special problem with the DFX turbo V-8 racing engines (introduced 1976) that Cosworth was producing for US Champ Car racing: The aluminum around exhaust valve seats was becoming soft and punky, sometimes resulting in loose seat rings. Something was happening to the metal. But what? Duckworth sought expert help.

In general, breakthroughs in science or engineering result from need and not from the brilliant insights of any one person. We know, for example, that Watson, Crick, Wilkins, and Franklin first revealed the dual-helical structure of DNA. But in the US, Linus Pauling’s group was only weeks behind, and countless others were hard at work on the problem.

The limited fatigue strength of castings, particularly when compared with that of forgings, long set a troublesome barrier to their wider use in highly stressed structural applications. That put many investigators to work on the problem.

Although at present several proprietary new-technology casting processes are delivering excellent parts with near-forged properties, it was Englishman John Campbell, author of the book Castings, first published in 1991, who has most comprehensively presented the underlying science to the world.

A remedy to Cosworth’s problems with DFX cylinder heads took the form of what Campbell in his book calls “quiescent melt handling.” Prior to its adoption, the scrap rate for DFX heads was 50 percent. Once it was put into practice, rejections ceased.

In most traditional casting, molten metal is poured into molds from above, and the process creates considerable turbulence. It had earlier been discovered at Cosworth that the longer molten metal “rested” before entering the mold, the less porosity resulted. Others had discovered value in filtering the metal. Another discovery was that the aluminum oxide “skin” that forms atop molten metal can be entrained by rapid pouring. Once in the melt, this skin folds against itself to form a “bifilrn” that does not bond to the metal, and so constitutes a plane of weakness.

New practice since the turn of this century fills molds from the bottom, and at a controlled and much lower rate that allows the oxide film to float atop the melt and be carried out through mold vents rather than being entrained in the flow to become part of the solidified casting.

The result of these new understandings has been castings of markedly greater strength, allowing motorcycles to lose roughly 30 pounds of weight.

Another result has been die castings that can be welded. In the past, attempts to heat-treat or to weld aluminum die castings have resulted in exfoliation, the metal then resembling wrinkled pages in a book, as entrained gas expanded. As the new methods have been refined, the minimum thickness of a casting has been greatly reduced: Yamaha recently reported that its current CF (Controlled Fill) process can reliably form parts whose minimum section is 1,7mm (0.067 inch), less than half the minimum achievable when the process was new. This is important because a major shortcoming of motorcycle chassis employing extruded or pressed sheet metal beams is that part wall thickness is constant. Because stress cannot be uniformly distributed everywhere, this means that some parts of such chassis are too thick. The new casting methods allow metal thickness to vary from place to place, to make it proportional to local stress.

The result of these new understandings has been castings of markedly greater strength...

One requirement for this is mold heating that does not chill the entering metal so that it fails to fill completely (called cold shorting). Another essential is the ability to nondestructively measure parts as they are made, to ensure dimensional correctness.

Recent motorcycle chassis, such as that of Aprilia’s 660 or the current-generation Yamaha MT-09, are made in two halves bolted together to make a complete unit. This accomplishes the goal of achieving net shape, needing only finish machining of things like steering-head bearing counterbores and swingarm pivots.

Despite the achievements of modern manufacturing, some of us feel nostalgia for craftsmanship. We must remember that it is just these low-cost but high-quality production methods that make it possible for so many of us to enjoy such excellent motorcycles. Craftsmanship can produce wonderful things; I think of the graceful swingarm of Aprilia’s RS250 GP racer. But the skills and time required put their price beyond our reach.

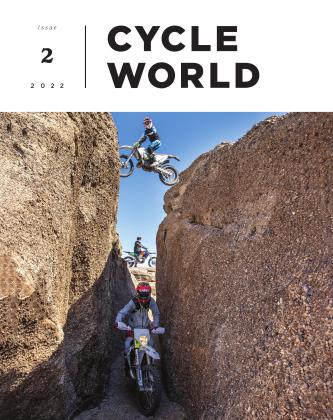

View Full Issue

View Full Issue

More From This Issue

-

ORIGINS

ORIGINSORIGINAL LUXURY

Issue 2 2022 By KEVIN CAMERON -

The OWNER

The OWNERTHE SURVIVOR

Issue 2 2022 By ANDREA WILSON -

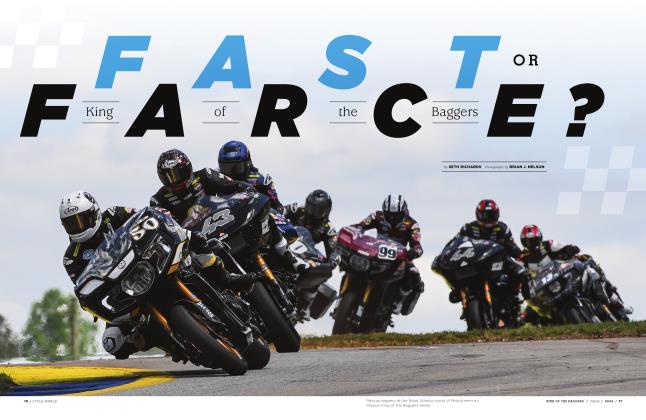

FAST OR FARCE King of the Baggers

Issue 2 2022 By SETH RICHARDS -

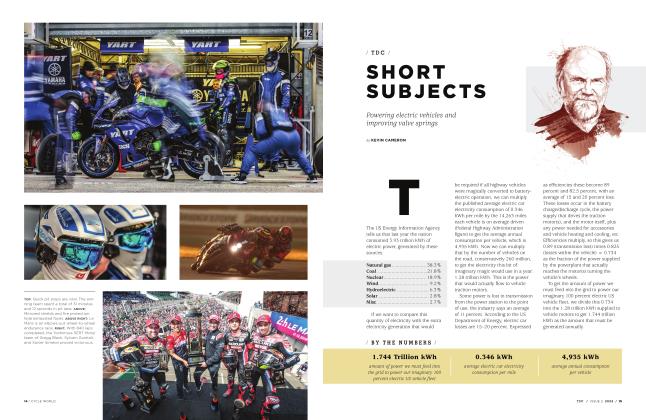

TDC

TDCSHORT SUBJECTS

Issue 2 2022 By KEVIN CAMERON -

UP FRONT

UP FRONTUPSIDES

Issue 2 2022 By MARK HOYER -

PHOTO ESSAY

PHOTO ESSAY24 HEURES MOTOS

Issue 2 2022 By Michael Gilbert