SHORT SUBJECTS

Powering electric vehicles and improving valve springs

March 1 2022 KEVIN CAMERONPowering electric vehicles and improving valve springs

March 1 2022 KEVIN CAMERONSHORT SUBJECTS

TDC

Powering electric vehicles and improving valve springs

KEVIN CAMERON

The US Energy Information Agency tells us that last year the nation consumed 3.93 trillion kWh of electric power, generated by these sources:

Natural gas 38.3%

Coal 21.8%

Nuclear 18.9%

Wind 9.2%

Hydroelectric 6.3%

Solar 2.8%

Misc 2.7%

If we want to compare this quantity of electricity with the extra electricity generation that would be required if all highway vehicles were magically converted to batteryelectric operation, we can multiply the published average electric car electricity consumption of 0.346 kWh per mile by the 14,263 miles each vehicle is on average driven (Federal Highway Administration figure) to get the average annual consumption per vehicle, which is 4,935 kWh. Now we can multiply that by the number of vehicles on the road, conservatively 260 million, to get the electricity this bit of imaginary magic would use in a year: 1.28 trillion kWh. This is the power that would actually flow to vehicle traction motors.

Some power is lost in transmission from the power station to the point of use; the industry says an average of 11 percent. According to the US Department of Energy, electric car losses are 15-20 percent. Expressed as efficiencies these become 89 percent and 82.5 percent, with an average of 15 and 20 percent loss. These losses occur in the battery charge/discharge cycle, the power supply that drives the traction motor(s), and the motor itself, plus any power needed for accessories and vehicle heating and cooling, etc. Efficiencies multiply, so this gives us 0.89 (transmission loss) times 0.825 (losses within the vehicle) = 0.734 as the fraction of the power supplied by the powerplant that actually reaches the motor(s) turning the vehicle’s wheels.

To get the amount of power we must feed into the grid to power our imaginary 100 percent electric US vehicle fleet, we divide this 0.734 into the 1.28 trillion kWh supplied to vehicle motors to get 1.744 trillion kWh as the amount that must be generated annually.

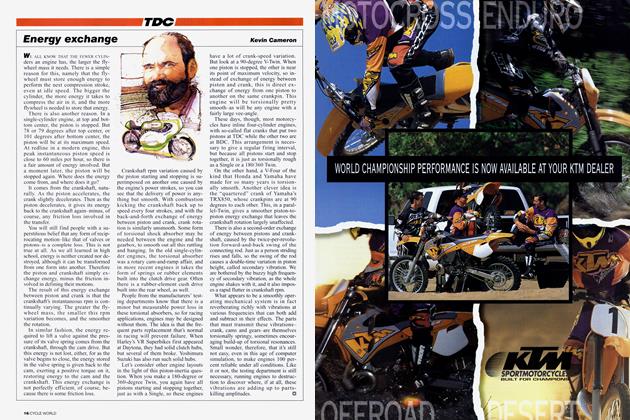

/ BY THE NUMBERS /

1.744 Trillion kWh

amount of power we must feed into the grid to power our imaginary 100 percent electric US vehicle fleet

0.346 kWh

average electric car electricity consumption per mile

4,935 kWh

average annual consumption per vehicle

“Conclusion: Metal springs must have improved a lot in the past 18 years. ”

As a percentage of total US electricity consumption in 2021 this is 1.744 43.93 = 44 percent. Some interested parties insist that this extra power can easily be found by just “turning up” existing power plants, making it unnecessary to build any new ones.

Whether that is true or not, one thing is certain: 44 percent more energy will have to be found as more fuel (fossil or nuclear), as more wind turbines, solar arrays, or hydroelectric dams. The above list of sources in use during 2021 shows that 61.4 percent of US electric power came from combustion and another 18.9 percent came from the nuclear power that environmentalists once disliked so intensely.

Another subject that has recently caught my interest is valve springs. We know that by 2004 MotoGP teams were changing their sagging, fatiguecracking metal valve springs every night, forcing a rapid transition to pneumatic springs. Yet pneumaticvalve MotoGP bikes are now often less than two seconds a lap quicker than World Superbikes, in which metal springs are still widely used; every bike but the desmo Ducatis has them.

Conclusion: Metal springs must have improved a lot in the past 18 years.

The Japanese firm Kobe Steel, a source of high-quality spring wire for years, has told its story. Kobe process engineers in detail improved long-established manufacturing techniques to result in a finer-grained and stronger material whose ultimate tensile strength can be as high as 320,000 pounds per square inch.

I discovered this work by accident. In reading about the development of Yamaha’s R1 1,000cc sportbike, I saw a note that the 2012 model (R1 ’s seventh generation) would receive valve springs of “VX Alloy.” When I searched for it online I found a family of alloys including SWOSC-VX, made by Japan’s Kobe Steel Co.

Kobe found detailed ways to extend the effect of techniques long used in the manufacture of spring wire. Chrome-vanadium steels gain strength from extremely fine grain and have long existed. Fine grain boosts strength because grain boundaries impede or stop the movement of the “dislocations,” or defects in crystal order, by which metals yield under stress. Metallurgists call this grain boundary pinning. Kobe researchers found that even finer grain and higher strength were possible with shorter, more tightly controlled heat treat. Traditional processing in furnaces reduced strength by allowing larger grains to grow at the expense of smaller ones. Kobe developed a quicker process based on electrical induction heating.

During manufacturing, steel wire also loses strength from chemical and physical effects that have traditionally been dealt with by shot-peening. But some practical-minded person went further: Why not just remove damaged surface layers entirely by drawing the wire through sharp-edged peeling dies? That, plus carefully optimized shot-peening, enhanced material properties even more.

All metals contain nonmetallic inclusions, usually oxides, large enough to nucleate cracking. Such techniques as remelting in a vacuum have been used since the 1950s to boil away the inclusions—but some always remained. Is there a way to break them up, making them too small to nucleate cracking? One way was to heat the wire and pull it through dies to elongate the inclusions. Get the temperature and rate of deformation of the metal through the die just right and the stringlike inclusions were stretched until they broke—and the fragments then shrank into harmless tiny globules.

It was tricky to get this right. How about lowering the melting temperature of the inclusions by chemically altering them? But be careful—anything that heats the metal can slightly reverse the process of grain refinement, so lower temperature and shorter exposure are better.

The result has been a process that has made exotic racing valve spring quality cheap enough that millions of production cars and motorcycles can now have such extraordinary springs. They combine extreme strength, fatigue resistance, and resistance to sag. High strength has made it possible to get excellent valve control from a smaller mass of spring wire—I saw tall 13-coil valve spring nested pairs going into Honda Interceptor superbike engines in 1983 that would today be replaced by shorter, lighter single springs with only four coils.

View Full Issue

View Full Issue

More From This Issue

-

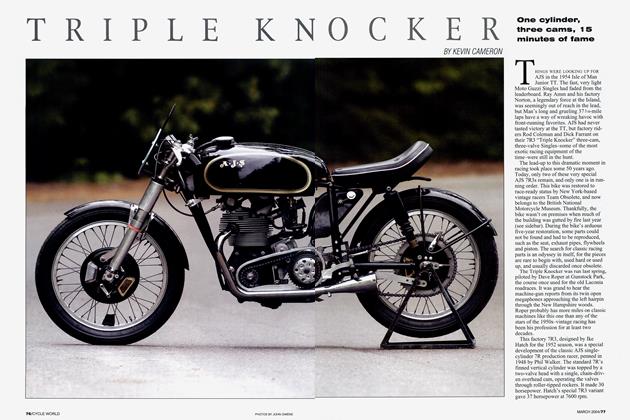

ORIGINS

ORIGINSORIGINAL LUXURY

Issue 2 2022 By KEVIN CAMERON -

The OWNER

The OWNERTHE SURVIVOR

Issue 2 2022 By ANDREA WILSON -

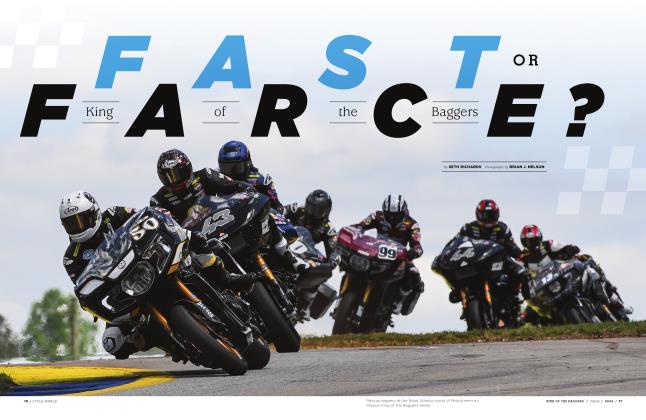

FAST OR FARCE King of the Baggers

Issue 2 2022 By SETH RICHARDS -

ELEMENTS

ELEMENTSCONTROLLED FILL

Issue 2 2022 By KEVIN CAMERON -

UP FRONT

UP FRONTUPSIDES

Issue 2 2022 By MARK HOYER -

PHOTO ESSAY

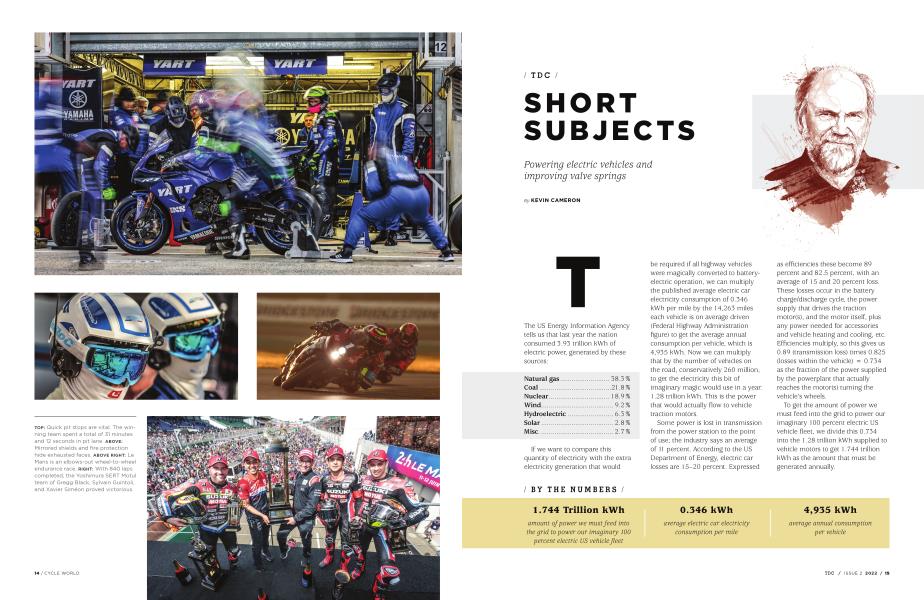

PHOTO ESSAY24 HEURES MOTOS

Issue 2 2022 By Michael Gilbert