TOUGH AND PURE

ELEMENTS

Stainless Steel has the power to resist

KEVIN CAMERON

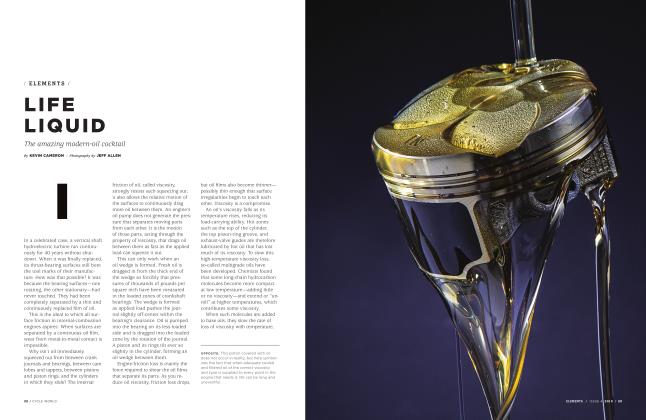

Stainless-steel alloys are today found on motorcycles mainly in the form of exhaust valves and exhaust systems. So well-adapted to their purpose have these alloys become that there is no longer even a memory of the exhaust-valve problems that plagued early motoring.

Records of racing at England’s great Brooklands Speedway show exhaust-valve failures as third-most-frequent behind drive-belt and spark-plug trouble. The chauffeurs of moneyed early motorists attended mandatory service schools, learning to regrind valve seatings every six weeks to restore the seal steadily destroyed by intense heat and corrosion.

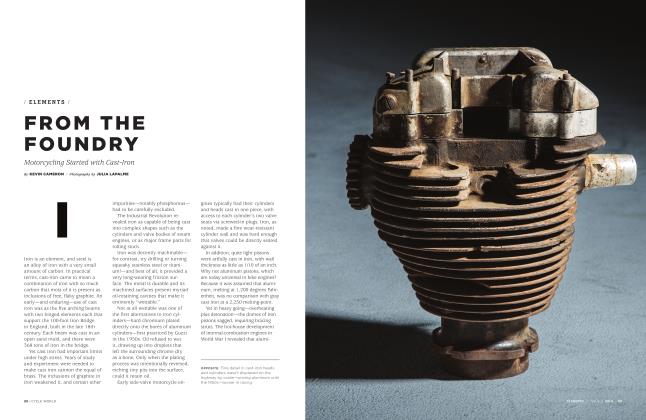

Early engines were given exhaust valves riveted together from a castiron head—they make stoves out of iron, right?—and a carbon-steel stem. Seeking some better solution, engineering pioneer Frederick Lanchester devised a single-valve system, functioning alternately as intake and exhaust, as a means of cooling the hard-worked metal. When the machine-tool industry developed so-called tungsten “highspeed steel” cutting tools, which remained hard even when red hot, they were eagerly adopted as exhaust-valve materials.

Yet valves went right ahead gradually losing seal from corrosion, stretching from high temperature and strong valve springs, and being a continuing menace to reliability.

Help was on the way. In England, Harry Brearly—seeking more corrosion-resistant materials for gun-barrel manufacture—discovered in 1913 that alloys of iron with at least 10.5 percent chromium displayed greatly enhanced resistance to the erosion of hot-propellant combustion. Chromium reacts with the oxygen in air to form a continuous and strongly bonded surface layer of chromium oxide, a ceramic. This layer protects the iron from oxidation. Victoryl

From Brearly’s work quickly evolved the food-grade stainless alloy known to this day as “18-8.” Those numbers, seen on tableware and cookware, indicate the presence of 18 percent chromium and 8 nickel in the material. Today, stainless flatware has almost completely displaced actual silverware—and the weekly ritual of polishing it.

By 1923, research had produced a stainless exhaust-valve alloy familiar to all fanciers of older British motorcycles: KE965. It had the remarkable property of being compatible with fuels containing the anti-knock catalyst tetraethyl lead—now banned from motor gasolines because it poisons catalytic mufflers...and also people.

The father of the high-power aircooled engine, S.D. Heron, noted in a 1920s test that while a stainless valve was relatively unaffected by the new leaded fuels—which were to be essential to ultimate Allied predominance in World War II aviation—a tungsten-steel valve of the older technology, after three hours’ running “Looked as though it had been dipped in liquid slag.”

Because more durable exhaust valves were a continuing necessity in the large aircraft piston engines developed 1930-1957, a wide range of materials and technologies evolved. These would include internal cooling by partial sodium filling and hard-facing of the sealing surface with the everything-resisting, Stellite, a cobalt = chromium alloy.

Fortunately for us, exhaust-valve working conditions in most modern motorcycle engines are benign by comparison. Small diameter makes it easy and quick for heat to flow from the hot center of the valve head to the valve seat that provides most of its cooling. The adoption of liquid-cooling in most modern engines has put an end to valve-temperature problems. Even in those classic air-cooled designs still made today, intensive local liquid-cooling of exhaust valve seats has often been adopted, by circulation of either engine oil or water/anti-freeze around or near the seat.

In exhaust systems, stainless continues to compete with titanium. For the lightness of titanium you pay a premium price, but stainless provides durability and enduring bright appearance at lower cost.

The 300-series stainless alloys are non-magnetic and cannot be hardened, causing my dad some frustration when he tried to sharpen 1950s knives made from them. I first encountered high-strength 17-4 PH stainless in a motorcycle axle that the distinguished constructor Harry Hunt had made for one of his projects. (Remember Hunt aluminum brake discs?)

Stainless fasteners compete with titanium as replacements for the zincor cadmium-plated steel OEM items. If an engine is apart frequently—as it is in racing—the plating wears off of stock-case screws at points of tool pressure, allowing in time a hint of rust. This offends some of us so much that forever-bright alternatives are necessary. In restoring veteran bikes of the nickel-plating era, making handlebars and other parts in stainless provides a period look that can never wear through.

Because they work-harden, stainless alloys are tricky to machine— you have to “stay under the chip.” Drilling stainless can be especially troublesome. Stainless also makes a poor friction partner. For that reason, many exhaust valves are made in two pieces friction-welded together: a heat-tolerant stainless head and a seizure-resistant carbon-steel stem.

Stainless steels are attractive for many purposes—good materials to learn more about. And they TIG weld beautifully.

View Full Issue

View Full Issue

More From This Issue

-

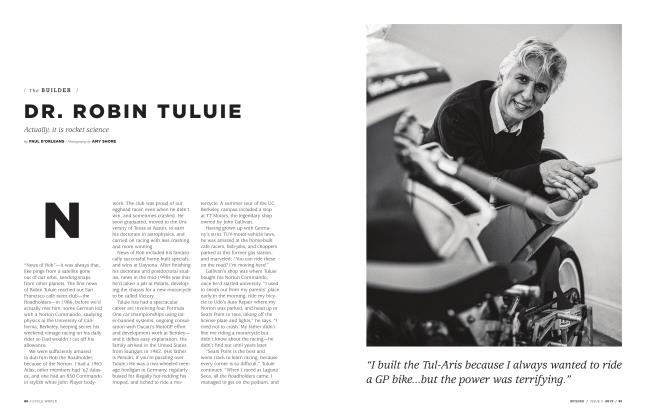

The Builder

The BuilderDr. Robin Tuluie

Issue 3 2019 By Paul d’Orléans -

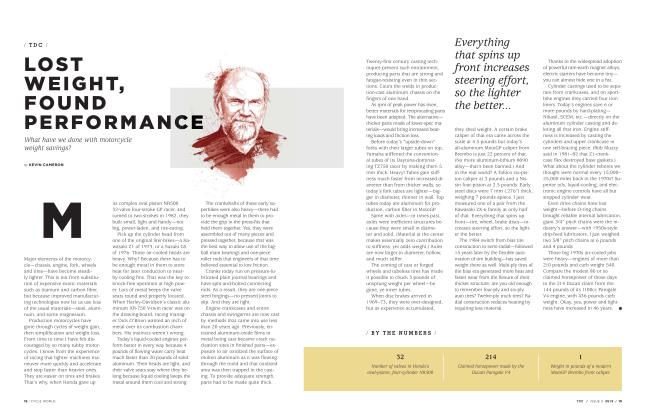

TDC

TDCLost Weight, Found Performance

Issue 3 2019 By Kevin Cameron -

Fundamentals

FundamentalsThe Clutch

Issue 3 2019 By Kevin Cameron -

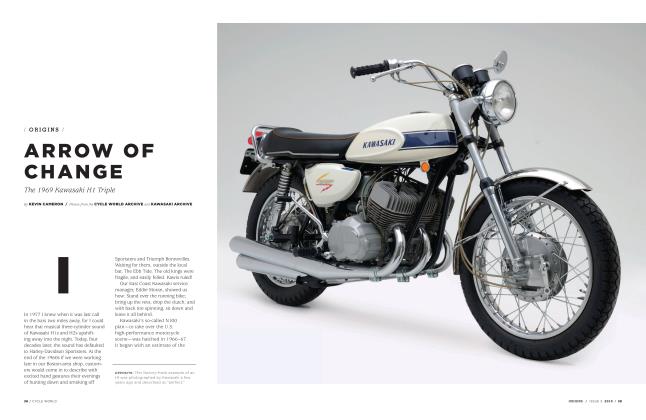

Origins

OriginsArrow of Change

Issue 3 2019 By Kevin Cameron -

Burning Rubber

Issue 3 2019 By Adam Waheed -

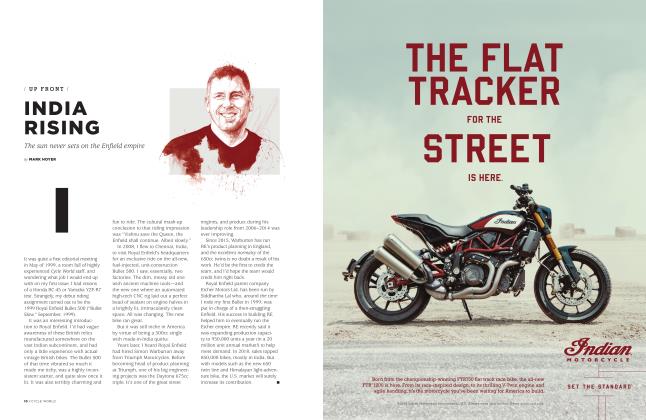

Up Front

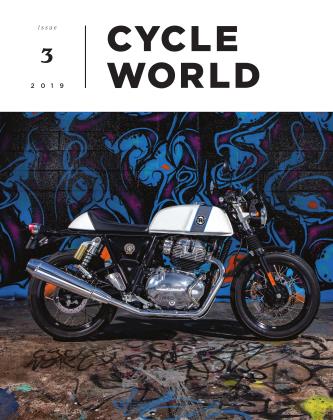

Up FrontIndia Rising

Issue 3 2019 By Mark Hoyer