Lost Weight, Found Performance

What have we done with motorcycle weight savings?

July 1 2019 Kevin CameronWhat have we done with motorcycle weight savings?

July 1 2019 Kevin CameronLOST WEIGHT, FOUND PERFORMANCE

TDC

What have we done with motorcycle weight savings?

KEVIN CAMERON

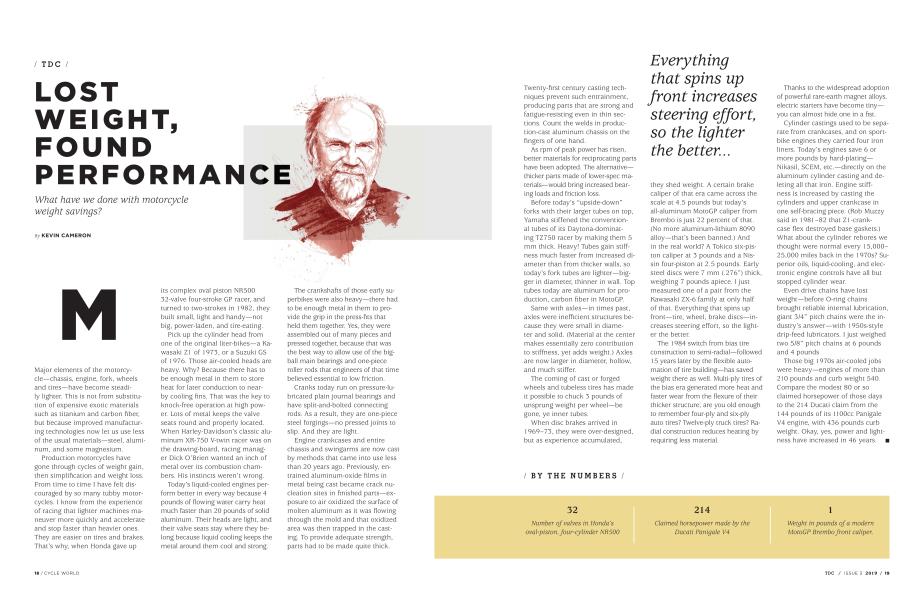

Major elements of the motorcycle—chassis, engine, fork, wheels and tires—have become steadily lighter. This is not from substitution of expensive exotic materials such as titanium and carbon fiber, but because improved manufacturing technologies now let us use less of the usual materials—steel, aluminum, and some magnesium.

Production motorcycles have gone through cycles of weight gain, then simplification and weight loss. From time to time I have felt discouraged by so many tubby motorcycles. I know from the experience of racing that lighter machines maneuver more quickly and accelerate and stop faster than heavier ones. They are easier on tires and brakes. That’s why, when Honda gave up its complex oval piston NR500 32-valve four-stroke GP racer, and turned to two-strokes in 1982, they built small, light and handy—not big, power-laden, and tire-eating.

Pick up the cylinder head from one of the original liter-bikes—a Kawasaki Z1 of 1973, or a Suzuki GS of 1976. Those air-cooled heads are heavy. Why? Because there has to be enough metal in them to store heat for later conduction to nearby cooling hns. That was the key to knock-free operation at high power. Lots of metal keeps the valve seats round and properly located. When Harley-Davidson’s classic aluminum XR-750 V-twin racer was on the drawing-board, racing manager Dick O’Brien wanted an inch of metal over its combustion chambers. His instincts weren’t wrong.

Today’s liquid-cooled engines perform better in every way because 4 pounds of flowing water carry heat much faster than 20 pounds of solid aluminum. Their heads are light, and their valve seats stay where they belong because liquid cooling keeps the metal around them cool and strong.

The crankshafts of those early superbikes were also heavy—there had to be enough metal in them to provide the grip in the press-fits that held them together. Yes, they were assembled out of many pieces and pressed together, because that was the best way to allow use of the bigball main bearings and one-piece roller rods that engineers of that time believed essential to low friction.

Cranks today run on pressure-lubricated plain journal bearings and have split-and-bolted connecting rods. As a result, they are one-piece steel forgings—no pressed joints to slip. And they are light.

Engine crankcases and entire chassis and swingarms are now cast by methods that came into use less than 20 years ago. Previously, entrained aluminum-oxide films in metal being cast became crack nucleation sites in finished parts—exposure to air oxidized the surface of molten aluminum as it was flowing through the mold and that oxidized area was then trapped in the casting. To provide adequate strength, parts had to be made quite thick. Twenty-first century casting techniques prevent such entrainment, producing parts that are strong and fatigue-resisting even in thin sections. Count the welds in production-cast aluminum chassis on the fingers of one hand.

Everything that spins up front increases steering effort, so the lighter the better...

As rpm of peak power has risen, better materials for reciprocating parts have been adopted. The alternativethicker parts made of lower-spec materials—would bring increased bearing loads and friction loss.

Before today’s “upside-down” forks with their larger tubes on top, Yamaha stiffened the conventional tubes of its Daytona-dominating TZ750 racer by making them 5 mm thick. Heavy! Tubes gain stiffness much faster from increased diameter than from thicker walls, so today’s fork tubes are lighter—bigger in diameter, thinner in wall. Top tubes today are aluminum for production, carbon fiber in MotoGP.

Same with axles—in times past, axles were inefficient structures because they were small in diameter and solid. (Material at the center makes essentially zero contribution to stiffness, yet adds weight.) Axles are now larger in diameter, hollow, and much stiffen

The coming of cast or forged wheels and tubeless tires has made it possible to chuck 3 pounds of unsprung weight per wheel—be gone, ye inner tubes.

When disc brakes arrived in 1969-73, they were over-designed, but as experience accumulated, they shed weight. A certain brake caliper of that era came across the scale at 4.5 pounds but today’s all-aluminum MotoGP caliper from Brembo is just 22 percent of that. (No more aluminum-lithium 8090 alloy—that’s been banned.) And in the real world? A Tokico six-piston caliper at 3 pounds and a Nissin four-piston at 2.5 pounds. Early steel discs were 7 mm (.276”) thick, weighing 7 pounds apiece. I just measured one of a pair from the Kawasaki ZX-6 family at only half of that. Everything that spins up front—tire, wheel, brake discs—increases steering effort, so the lighter the better.

The 1984 switch from bias tire construction to semi-radial—followed 15 years later by the flexible automation of tire building—has saved weight there as well. Multi-ply tires of the bias era generated more heat and faster wear from the flexure of their thicker structure; are you old enough to remember four-ply and six-ply auto tires? Twelve-ply truck tires? Radial construction reduces heating by requiring less material.

Thanks to the widespread adoption of powerful rare-earth magnet alloys, electric starters have become tiny— you can almost hide one in a fist.

Cylinder castings used to be separate from crankcases, and on sportbike engines they carried four iron liners. Today’s engines save 6 or more pounds by hard-plating— Nikasil, SCEM, etc.—directly on the aluminum cylinder casting and deleting all that iron. Engine stiffness is increased by casting the cylinders and upper crankcase in one self-bracing piece. (Rob Muzzy said in 1981-82 that Z1-crankcase flex destroyed base gaskets.) What about the cylinder rebores we thought were normal every 15,GOO25,000 miles back in the 1970s? Superior oils, liquid-cooling, and electronic engine controls have all but stopped cylinder wear.

Even drive chains have lost weight—before O-ring chains brought reliable internal lubrication, giant 3/4” pitch chains were the industry’s answer—with 1950s-style drip-feed lubricators. I just weighed two 5/8” pitch chains at 6 pounds and 4 pounds

Those big 1970s air-cooled jobs were heavy—engines of more than 210 pounds and curb weight 540. Compare the modest 80 or so claimed horsepower of those days to the 214 Ducati claim from the 144 pounds of its llOOcc Panigale V4 engine, with 436 pounds curb weight. Okay, yes, power and lightness have increased in 46 years.

BY THE NUMBERS

32

Number of valves in Honda’s oval-piston, four-cylinder NR500

214

Claimed horsepower made by the Ducati Panigale V4

1

Weight in pounds of a modern MotoGP Brembo front caliper.

View Full Issue

View Full Issue

More From This Issue

-

The Builder

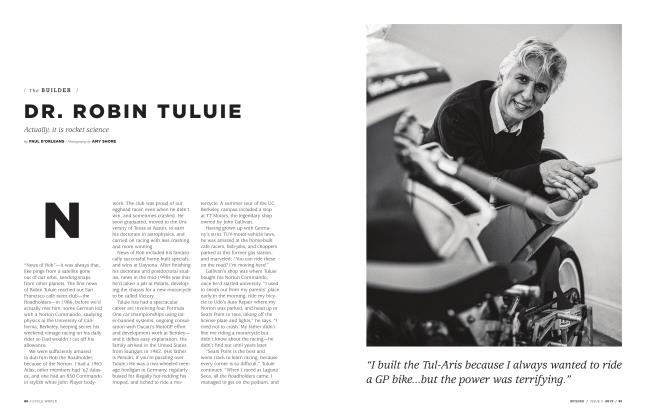

The BuilderDr. Robin Tuluie

Issue 3 2019 By Paul d’Orléans -

Fundamentals

FundamentalsThe Clutch

Issue 3 2019 By Kevin Cameron -

Origins

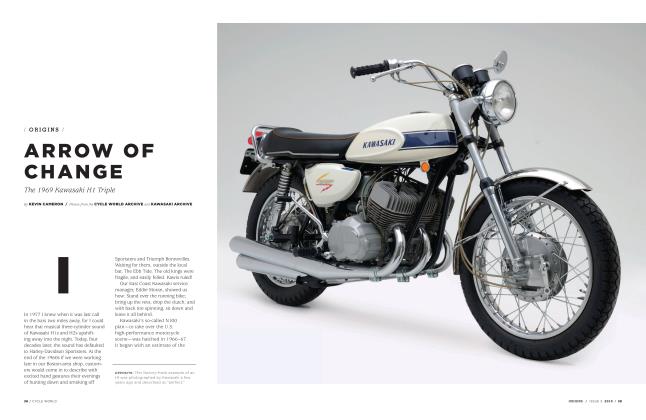

OriginsArrow of Change

Issue 3 2019 By Kevin Cameron -

Elements

ElementsTough And Pure

Issue 3 2019 By Kevin Cameron -

Burning Rubber

Issue 3 2019 By Adam Waheed -

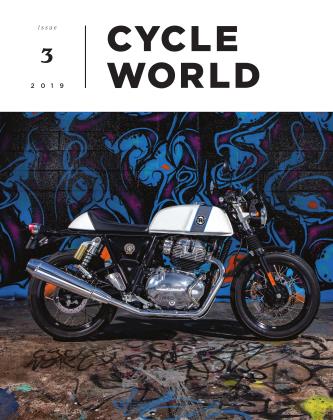

Up Front

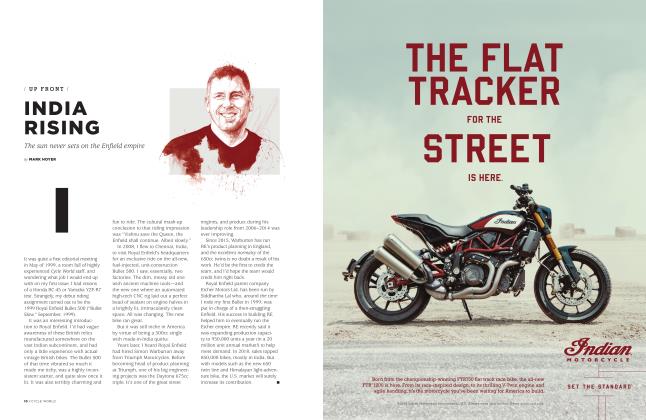

Up FrontIndia Rising

Issue 3 2019 By Mark Hoyer