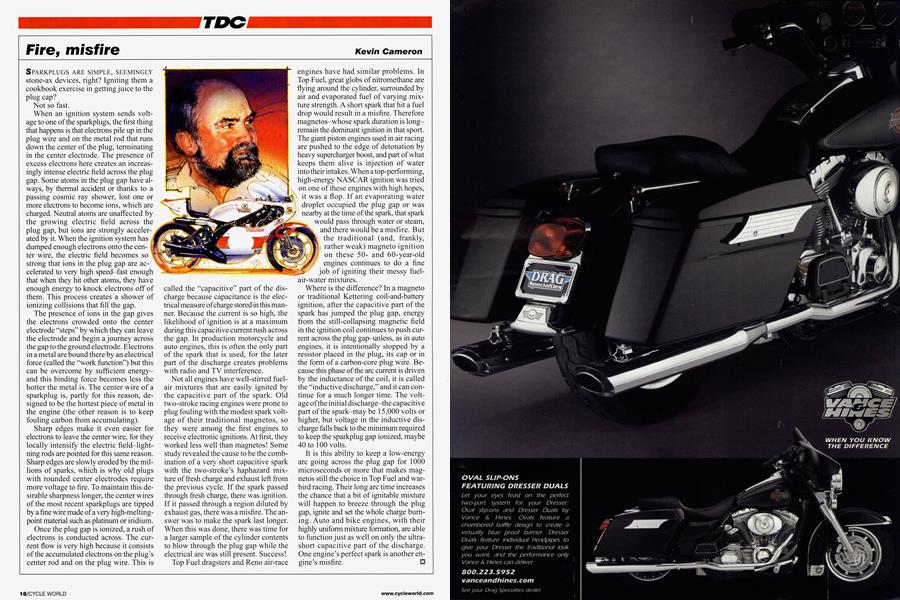

Fire, misfire

TDC

Kevin Cameron

SPARKPLUGS ARE SIMPLE, SEEMINGLY stone-ax devices, right? Igniting them a cookbook exercise in getting juice to the plug cap?

Not so fast.

When an ignition system sends voltage to one of the sparkplugs, the first thing that happens is that electrons pile up in the plug wire and on the metal rod that runs down the center of the plug, terminating in the center electrode. The presence of excess electrons here creates an increasingly intense electric field across the plug gap. Some atoms in the plug gap have always, by thermal accident or thanks to a passing cosmic ray shower, lost one or more electrons to become ions, which are charged. Neutral atoms are unaffected by the growing electric field across the plug gap, but ions are strongly accelerated by it. When the ignition system has dumped enough electrons onto the center wire, the electric field becomes so strong that ions in the plug gap are accelerated to very high speed-fast enough that when they hit other atoms, they have enough energy to knock electrons off of them. This process creates a shower of ionizing collisions that fill the gap.

The presence of ions in the gap gives the electrons crowded onto the center electrode “steps” by which they can leave the electrode and begin a journey across the gap to the ground electrode. Electrons in a metal are bound there by an electrical force (called the “work function”) but this can be overcome by sufficient energyand this binding force becomes less the hotter the metal is. The center wire of a sparkplug is, partly for this reason, designed to be the hottest piece of metal in the engine (the other reason is to keep fouling carbon from accumulating).

Sharp edges make it even easier for electrons to leave the center wire, for they locally intensify the electric field-lightning rods are pointed for this same reason. Sharp edges are slowly eroded by the millions of sparks, which is why old plugs with rounded center electrodes require more voltage to fire. To maintain this desirable sharpness longer, the center wires of the most recent sparkplugs are tipped by a fine wire made of a very high-meltingpoint material such as platinum or iridium.

Once the plug gap is ionized, a rush of electrons is conducted across. The current flow is very high because it consists of the accumulated electrons on the plug’s center rod and on the plug wire. This is called the “capacitive” part of the discharge because capacitance is the electrical measure of charge stored in this manner. Because the current is so high, the likelihood of ignition is at a maximum during this capacitive current rush across the gap. In production motorcycle and auto engines, this is often the only part of the spark that is used, for the later part of the discharge creates problems with radio and TV interference.

Not all engines have well-stirred fuelair mixtures that are easily ignited by the capacitive part of the spark. Old two-stroke racing engines were prone to plug fouling with the modest spark voltage of their traditional magnetos, so they were among the first engines to receive electronic ignitions. At first, they worked less well than magnetos! Some study revealed the cause to be the combination of a very short capacitive spark with the two-stroke’s haphazard mixture of fresh charge and exhaust left from the previous cycle. If the spark passed through fresh charge, there was ignition. If it passed through a region diluted by exhaust gas, there was a misfire. The answer was to make the spark last longer. When this was done, there was time for a larger sample of the cylinder contents to blow through the plug gap while the electrical arc was still present. Success!

Top Fuel dragsters and Reno air-race engines have had similar problems. In Top Fuel, great globs of nitromethane are flying around the cylinder, surrounded by air and evaporated fuel of varying mixture strength. A short spark that hit a fuel drop would result in a misfire. Therefore magnetos-whose spark duration is longremain the dominant ignition in that sport. The giant piston engines used in air racing are pushed to the edge of detonation by heavy supercharger boost, and part of what keeps them alive is injection of water into their intakes. When a top-performing, high-energy NASCAR ignition was tried on one of these engines with high hopes, it was a flop. If an evaporating water droplet occupied the plug gap or was nearby at the time of the spark, that spark would pass through water or steam, and there would be a misfire. But the traditional (and, frankly, i rather weak) magneto ignition on these 50and 60-year-old engines continues to do a fine job of igniting their messy fuelair-water mixtures.

Where is the difference? In a magneto or traditional Kettering coil-and-battery ignition, after the capacitive part of the spark has jumped the plug gap, energy from the still-collapsing magnetic field in the ignition coil continues to push current across the plug gap-unless, as in auto engines, it is intentionally stopped by a resistor placed in the plug, its cap or in the form of a carbon-core plug wire. Because this phase of the arc current is driven by the inductance of the coil, it is called the “inductive discharge,” and it can continue for a much longer time. The voltage of the initial discharge-the capacitive part of the spark-may be 15,000 volts or higher, but voltage in the inductive discharge falls back to the minimum required to keep the sparkplug gap ionized, maybe 40 to 100 volts.

It is this ability to keep a low-energy arc going across the plug gap for 1000 microseconds or more that makes magnetos still the choice in Top Fuel and warbird racing. Their long arc time increases the chance that a bit of ignitable mixture will happen to breeze through the plug gap, ignite and set the whole charge burning. Auto and bike engines, with their highly uniform mixture formation, are able to function just as well on only the ultrashort capacitive part of the discharge. One engine’s perfect spark is another engine’s misfire.

View Full Issue

View Full Issue