FUELISHLY COMPLICATED

IGNITION

TDC

ENERGY SOURCES VERSUS ENERGY CARRIERS

KEVIN CAMERON

The fuel that most interests motorcyclists is gasoline because that's what almost all motorcycles burn. But the fuel that drives our lives is diesel, powering farming, all medium and heavy trucking, all the railroads save for the Northeast corridor, and all coastal and international shipping. If we add the lighter fractions based on 9 to 13 carbons per molecule, we include the kerosene-like fuels (Jet-A, JP4) that power aviation. In Europe, some 60 percent of new cars are delivered with diesel engines.

This is why, when synthetic fuel production is considered, the product in mind is always diesel.

I well remember being a small boy in my parents’ car, driving past the New Jersey refineries and seeing the ghostly wavering flames atop their flare stacks. Even today, petroleum gases are flared in some areas like Nigeria. Natural gas is highly valued today because its use allows power companies to meet emissions standards much more cheaply than they can with coal.

The big question is this: How do you get it from where it comes out of the ground to the point of use? Pipelines are one answer—much European electricity is generated from Russian gas. India and China would love to have gas from the rich Caspian Sea fields, but the necessary pipelines would have to be built across areas infested by unpleasant men with automatic weapons.

One answer is to refrigerate and compress natural gas into a liquid at 260 degrees Fahrenheit below zero then pump it (after carefully cooling the receiving tanks and all pumping apparatus and plumbing) into glorified spherical “thermos bottles” aboard special LNG (Liquefied Natural Gas) ships. Such ships, crewed by extremely careful non-smoking staff, then carry the liquid across the wide ocean without running aground or turning over in cruise-ship fashion. On the receiving end, there must be matching high-tech facilities and procedures for safe unloading and storage, costing hundreds of millions.

There must be endless permits and licenses, backed by learned deliberations, that say the chance of distressing accident or terrorist action can be reduced to an acceptably small value. Even with such deliberations, not all of us will agree, leading to op-eds in top newspapers, picketing, and lawsuits. Good luck.

But just as soon as everyone in the boardroom nods and signs off on funding all this, hydraulic fracturing, or fracking, comes along (even with all its controversies) and provides so much gas in the US that drilling rigs are now going back into storage at record rates. Too much gas!

Another way to transform natural gas into a liquid is to employ “GTL,” or Gas-toLiquids chemical conversion. Using high pressure, heat, and catalysts in the usual zillion-dollar plant, the natural gas can be reformed from its natural one-carbon state into species based on long carbon chains with 13 to 22 carbons each. GTL yields a wonderful synthetic diesel fuel that ignites easily in engines (high cetane rating), burns more cleanly than natural diesel (because it contains no rugged, combustion-resistant, soot-forming carbon ring structures), and, best of all, contains zero sulfur (so it cannot form sulfur dioxide and sulfuric acid when burned). Such diesel commands a substantially higher price in the market. Hmm.

But just as our boardroom execs set aside their half-eaten doughnuts to reach for their pens, news comes of Europe’s new awareness of health hazards from diesel emissions. The same thing happened in the US in the 1980s, when a researcher discovered that sitting, adsorbed, on the surfaces of diesel exhaust carbon particulates are some amazingly carcinogenic compounds based on carbon ring structures.

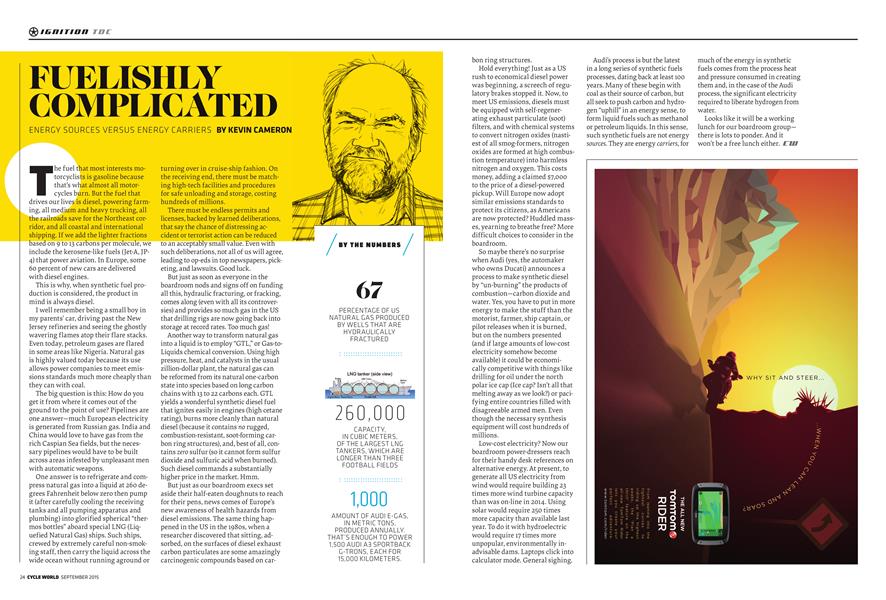

BY THE NUMBERS

67 PERCENTAGE OF US NATURAL GAS PRODUCED BY WELLS THAT ARE HYDRAULICALLY FRACTURED

260,000 CAPACITY, IN CUBIC METERS, OFTHE LARGEST LNG TANKERS, WHICH ARE LONGERTHAN THREE FOOTBALL FIELDS

1,000 AMOUNTOF AUDI E-GAS, IN METRICTONS, PRODUCED ANNUALLY. THAT’S ENOUGH TO POWER 1,500 AUDI A3 SPORTBACK G-TRONS, EACH FOR 15,000 KILOMETERS.

Hold everything! Just as a US rush to economical diesel power was beginning, a screech of regulatory brakes stopped it. Now, to meet US emissions, diesels must be equipped with self-regenerating exhaust particulate (soot) filters, and with chemical systems to convert nitrogen oxides (nastiest of all smog-formers, nitrogen oxides are formed at high combustion temperature) into harmless nitrogen and oxygen. This costs money, adding a claimed $7,000 to the price of a diesel-powered pickup. Will Europe now adopt similar emissions standards to protect its citizens, as Americans are now protected? Huddled masses, yearning to breathe free? More difficult choices to consider in the boardroom.

So maybe there’s no surprise when Audi (yes, the automaker who owns Ducati) announces a process to make synthetic diesel by “un-burning” the products of combustion—carbon dioxide and water. Yes, you have to put in more energy to make the stuff than the motorist, farmer, ship captain, or pilot releases when it is burned, but on the numbers presented (and if large amounts of low-cost electricity somehow become available) it could be economically competitive with things like drilling for oil under the north polar ice cap (Ice cap? Isn’t all that melting away as we look?) or pacifying entire countries filled with disagreeable armed men. Even though the necessary synthesis equipment will cost hundreds of millions.

Low-cost electricity? Now our boardroom power-dressers reach for their handy desk references on alternative energy. At present, to generate all US electricity from wind would require building 23 times more wind turbine capacity than was on-line in 2014. Using solar would require 250 times more capacity than available last year. To do it with hydroelectric would require 17 times more unpopular, environmentally inadvisable dams. Laptops click into calculator mode. General sighing.

Audi’s process is but the latest in a long series of synthetic fuels processes, dating back at least too years. Many of these begin with coal as their source of carbon, but all seek to push carbon and hydrogen “uphill” in an energy sense, to form liquid fuels such as methanol or petroleum liquids. In this sense, such synthetic fuels are not energy sources. They are energy carriers, for much of the energy in synthetic fuels comes from the process heat and pressure consumed in creating them and, in the case of the Audi process, the significant electricity required to liberate hydrogen from water.

Looks like it will be a working lunch for our boardroom group — there is lots to ponder. And it won’t be a free lunch either.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Ten Rest

September 2015 By Mark Hoyer -

Intake

IntakeIntake

September 2015 -

Ignition

IgnitionCw Product Spotlight Arai Corsair-X

September 2015 By Matthew Miles -

Ignition

IgnitionCw 25 Years Ago September 1990

September 2015 By Blake Conner -

Ignition

IgnitionKnow Yourself To Know Your Bike the Perfect Bike

September 2015 By John L. Stein -

Ignition

IgnitionThe Great Unconformity

September 2015 By Paul d’Orléans