CW PRODUCT SPOTLIGHT ARAI CORSAIR-X

IGNITION

PRODUCT SPOTLIGHT

Five things you need to know

Matthew Miles

1 Two words: round and smooth. Starting point for the Corsair-X is Arai’s customary egg-shaped shell. Company engineers call this “R75,” defined as a continuous, convex curve of a minimum radius of 75mm. Should the helmet glance off an object, energy-absorption capacity can be reserved for a second, third, or even fourth impact-what Arai calls the “realities” of a crash.

2 A fundamental difference: The Corsair-X has a new face shield system. This complicated yet elegant design uses Arai’s Variable Axis System (VAS) that lowers the operating mechanism, increasing the area above the side pods by an average of 24mm for a rounder, smoother surface along the critical Snell test line.

3 Let's face it: Many Americans have pronounced facial features. Comedian Jay Leno, an Arai wearer, is one well-publicized example. Arai addressed this challenge by extending the chin bar of the Corsair-X by 3mm and reshaping the liner to give the wearer more room and make the helmet feel less claustrophobic.

4 Also new: the central top of-shell intake vent. While the previous Delta 5 vent had a lower, wider profile, the new designpullsinmoreairandis less sensitive to the rider’s position on the motorcycle. Two-stop “slider gates" close more securely than the previous flappers, which helps reduce wind noise.

5 An added bonus: A secondary benefit of a smooth, round shell is that the helmet remains aerodynamic and quiet even when you turn your head. Small bulges in front of the air intakes in the 20mm-longer diffusers improve flow by a claimed 19 percent. Straightening the diffusers has enhanced overall stability.

FAST FACTS

→ An Arai shell expert (15 in the world) can produce either 110 fiberglass shells each day or one carbonfiber shell.

→ Flelmet molds are machined inhouse from steel ingots.

→ Strong shell, soft liner: Arai has 10 EPS liner-density options and engineers usually favor the softest possible combination for best energy absorption.

→ Each full-face Arai helmet has anywhere from 27 to 30 highly individual components, each precisely cut and shaped.

→ Prepping, applying, and sanding the base coat of paint for each shell requires five days of hand labor.

→ Arai employs 280 people at its main plant in Ohmiya, Japan; only three are certified to install chinstraps.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

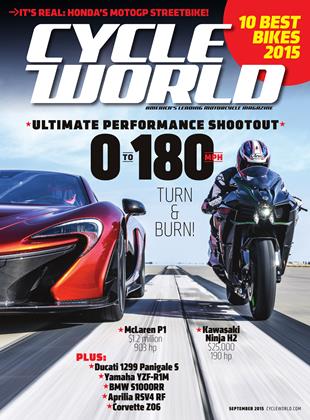

Up FrontThe Ten Rest

September 2015 By Mark Hoyer -

Intake

IntakeIntake

September 2015 -

Ignition

IgnitionCw 25 Years Ago September 1990

September 2015 By Blake Conner -

Ignition

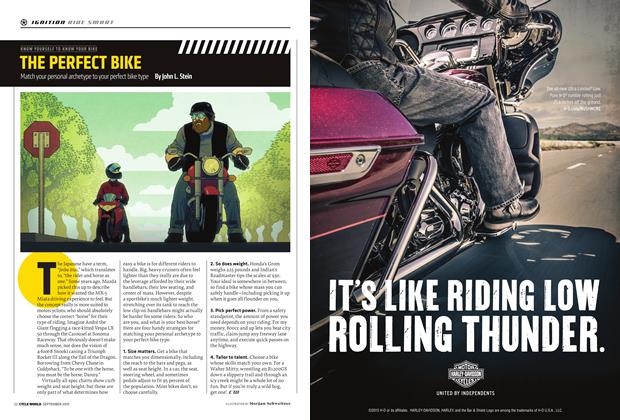

IgnitionKnow Yourself To Know Your Bike the Perfect Bike

September 2015 By John L. Stein -

Ignition

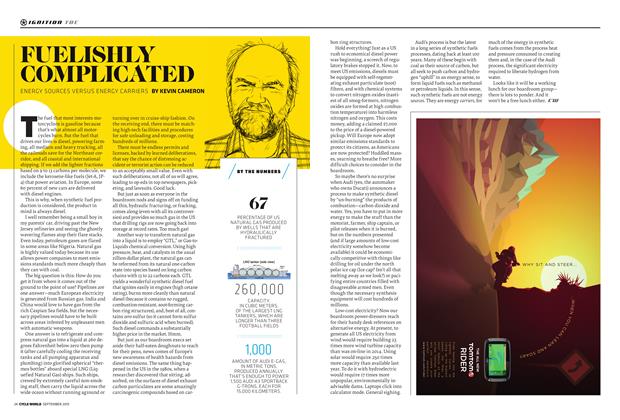

IgnitionFuelishly Complicated

September 2015 By Kevin Cameron -

Ignition

IgnitionThe Great Unconformity

September 2015 By Paul d’Orléans