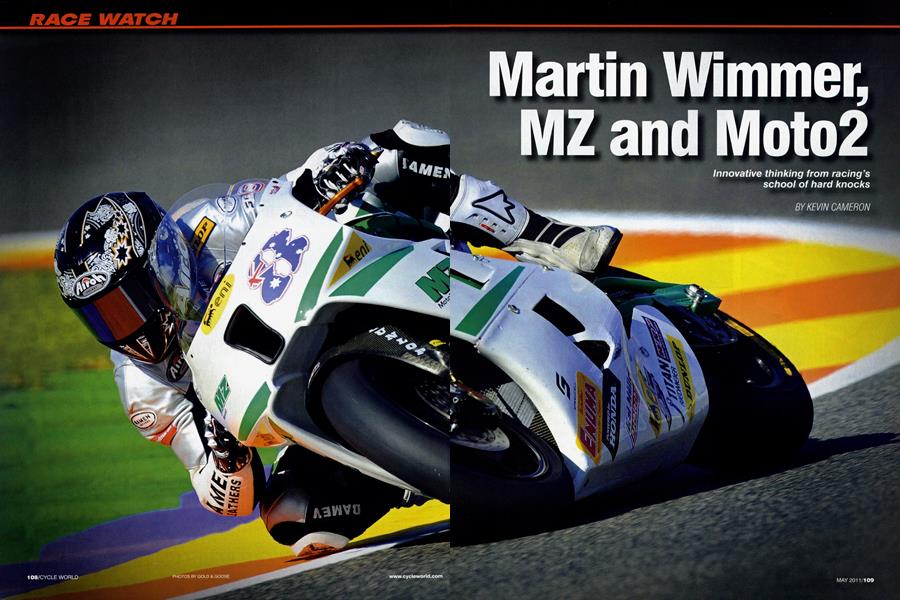

RACE WATCH

Martin Wimmer, MZ and Moto2

Innovative thinking from racing's school of hard knocks

KEVIN CAMERON

A T THE INDIANAPOLIS GRAND Piux LAST SUMMER, I WAS walking behind the garage building when a person scam pered up to me and said, "Martin Wimmer asks that you come to his garage." I was happy to follow him. I met Wimmer during the 1981 Grand Prix season when he was riding the German Yamaha importer's TZ25OH, and we were able to help each other that season. Wimmer was a gritty, determined competitor-one year, he rode the Laguna Seca event with his broken jaw wired shut. Most recently, Wimmer and another for mer 25 0cc GP rider, RalfWaldmann, bought the MZ motorcycle firm from the Hong Leong Group in early 2009 (it had ceased operations in 2008), with the intent of resuming two-wheel manu facturing. Waldmann has subsequently left the enterprise.

Now here was Wimmer, at the races with his own design for the brand-new spec-engine Moto2 class, which has now replaced 250cc GP. I was eager to see his bike and to hear what he had to say.

It was MZ in the 1950s that developed the basis of the modern two-stroke racing engine. The ideas of Daniel Zimmermann and Walter Kaaden were then rapidly developed by Japanese manufacturers, leading to two-stroke GP dominance from 1975 to 2001. MZ, located as it was in postwar Germany's

Soviet zone, had only the most limited resources. As I would learn, Wimmer was continuing MZ's tradition of making ideas do the work of money. His role there is "hands on."

Wimmer's Moto2 bike is conventional in the sense that it employs the predictable, available-to-everybody brakes, suspension and wheels. It is quite unconventional in having a steel-tube chassis.

"This is because at the MZ factory we have some very skilled old guys who know how to fabricate only from steel," said Wimmer. "We have no heliarc machines! Also, there is a lot of good steel material in our inventory. Therefore, we have made our frame of steel."

"Steel has three times the stiffness of aluminum, so if it is used properly, it can make a very strong chassis. After all, the landing gear of large aircraft is steel."

The initial swingarm design was not stiff enough, so Wimmer placed a long bar through the back of it and pulled while measuring the relative deflections of the arm's elements. In this way, he was able to discover where additional braces should be located to stiffen the part. As he described the work, his face became intensely animated.

"Is it so surprising to use steel?" Wimmer asked. "Steel has three times the stiffness of aluminum, so if it is used properly, it can make a very strong chassis. After all, the landing gear of large aircraft is steel."

The modified swingarm became very stiff. Wimmer commented that, "In this work, not one time was a computer used!" Much is made of modeling realworld problems in "silicon logic," but any good engineer constantly models reality in his/her "mind's eye." Given a choice between an experienced designer with a slide rule and a low-hours screen jockey at a workstation, which would you choose? Humans can decide. Silicon can only obey.

In early testing, the bike was not fast—it seemed down on power. All normal remedies failed. There was no apparent cause for this shortfall, and after much investigation, people on the MZ crew began to murmur among themselves, "We must now make an aluminum frame like those of the other teams."

Wimmer was unwilling to accept the idea that just replacing steel with aluminum might magically cause power to appear. Yet he wondered through what mechanism the difference in materials could affect engine power. Eventually, it came to him: the stiffness of steel! The front of the engine was supported by extensions of the two tubes welded to the bottom of the steering head. These "support spikes" bolted to bosses on the front of the engine's cylinder. Could it be that as the engine warmed up in operation, its aluminum cylinder block expanded but the stiffness of the steel mounts opposed its doing so, making the bores slightly oval? The manner of attachment was changed to allow free cylinder expansion, and bingo! full power returned.

I thought of the aspirin ad that showed a man with his head in a vise; this was the problem Wimmer had solved. Round piston rings in slightly oval cylinders had let 6 horsepower (4 percent) blow by. And he had solved it directly in the old MZ tradition of thinking carefully, then building. No rapid prototyping machines here. No high-end workstations running CATIA or SolidWorks. There is more. Wimmer has invented a novel front end for bicycles that might solve an outstanding problem of roadracing motorcycles. The problem is that the usual telescopic fork is pro-dive during braking, with about 8 percent of the braking force directly compressing the fork. This fork compression causes a loss of trail, or front wheel

self-centering effect, and can reduce braking stability. Riders, on the other hand, have historically sought to use less and less rake angle and trail. Rake in 1970 ranged from 27-31 degrees, but today it has become more like 23-25 degrees, while trail has decreased from 4.0-4.5 inches to 3.5-3.9. Braking instability caused by a telescopic fork's trail loss imposes a limit on how far steering geometry can be pushed toward lighter and quicker.

Originally, Wimmer was thinking about the problem of a downhill bicycle racer. The nose-down attitude of the machine transfers weight forward, causing a loss of trail through fork compression. If the bike now hits a bump, it has much the same effect as riding in deep sand: The terrain "gets a grip'' on the front wheel ahead of the steering axis, and this can instantly kick the steering to one side, pitching the rider on his/ her head. Extra trail acts as insurance against this but makes the steering heavier and slower. Naturally, just as in roadracing, everyone wants both stability and quick steering.

Could there be a way? Wimmer knew that with a suspension like BMW Telelever, the forward-facing A-frame that connected to the lower fork crown could be angled so that as the fork compressed, the angling of the A-frame woul d push the front axle forward, increasing trail. But could hie combine two systems in one—a pro-dive telescopic fork and a trail-extending Telelever-like action to give constant trail, even with full fork compression? Then quicker steering geometry would no longer invite braking instability.

Even today, many would say,

"Where's the problem? There are lots of anti-dive systems that offer constant trail. Why not use one of them?"

Sorry, people, catch up with the times. GP and Superbike teams experimented intensively with anti-dive systems 30 years ago. Kawasaki and Honda tested mechanical anti-dives, and Honda and Suzuki also investigated anti-dive based on increased compression damping. What they all learned was that dive is actively beneficial. It allows significantly harder braking because it lowers the machine-and-rider eg height. Anti-dive therefore went into history's dumpster.

Here is what Wimmer came up with. As with Telelever, the tops of the fork legs are joined by a hinged upper crown that pivots on a conventional steering head. A lower fork crown attaches not the steering head but via a ball joint to the forward end of an A-frame pivoted on the bike's frame. It is the fork legs that are unique, in that each female fork leg element is "double-ended," having two male sliders in it, one projecting from either end. The upward-projecting male sliders fasten into the upper crown, while the downward-projecting pair is joined at their bottoms by the front axle. The two female tubes are joined by the yoke that attaches to the A-arm.

This fork embodies two actions in one. Compression of the lower sliders reduces trail just as a telescopic fork does. Compression of the upper sliders increases it, as the A-arm swings upward, pushing the tubes slightly forward. By varying the rates of upper and lower springs, the percentages of each effect can be varied. By moving the A-arm's pivot forward or back, the total trail can be varied. By moving its pivot up or down, the degree of trail increase or "kick out" caused by the swing of the A-arm during compression can be varied.

Wimmer explained with burning gaze and demonic enthusiasm that this fork—because it is basically telescopic and so, pro-dive—will feel familiar and therefore reassuring to riders. Such reassuring "feel" was also a feature of John Britten's fork during three-fourths of its travel. But it will both solve the problem of stability reduction during braking and provide additional degrees of adjustability not present in previous suspensions.

When Moto2 was proposed as a replacement for the 250 GP class, its creators claimed that by adoption of identical-spec 130-hp Honda CBR600RR engines with chassis design left free, it would focus creativity on chassis, unlocking rapid change. Will Martin Wimmer bring his radical bicycle fork to Moto2, and can it be quickly enough made to work? Or will the natural conservatism of racing steer design back to sameness, as each team races to buy whichever chassis won last week's event? □

View Full Issue

View Full Issue