SERVICE

Arctic sport-touring

PAUL DEAN

Q I'm going to buy either a new Kawasaki Concours 14 or a Yamaha FJR1300 from a dealer that's 1000 miles from where I live. Once I have purchased it, I intend to ride it home. Here is my problem: The road home is long and straight with very little traffic. I know that manufacturers recommend breaking-in bikes at varying speeds with occasional light acceleration; so on my long ride home, what would be the best riding procedure for achieving a good break-in?

Also, I intend to store the bike in an unheated garage where the temperature often drops to -40 degrees Fahrenheit in the winter. I know from personal experience that cars and trucks are okay under such conditions, but would it be safe to store a bike at these temperatures? I’m particularly concerned about the percentage of anti-freeze in the coolant of a new bike, and how well the various seals

can withstand the cold. I would value your opinion. David Smith

Yellowknife, Northwest Territories, Canada

A For break-in, my advice is to follow the instructions in the owner’s manual as closely as is reasonable. As you indicate, your route home involves little traffic, so you should be able to ride at or near the recommended mph and vary your speed without any significant problems. And while you should not make any top-speed or max-acceleration runs on your ride home, you do not have to follow the manual’s recommendations to the exact letter. Years ago, break-in was much more critical than it is these days, thanks to huge advances in manufacturing and metallurgy. The bike-makers tend to be very conservative in their break-in procedures, enough so that if you were to encounter a situation that required you to ride faster for a brief spell or accelerate a bit more quickly, no engine damage would result.

Before riding away from the dealership, however, ask the people there to install enough anti-freeze in the cooling system to deal with 40-below temperatures. And also leave the shop with sufficient oil and a filter so you can have someone along the way (another bike shop, a service station or even by doing it yourself) change the oil at around 500-600 miles.

As far as storage is concerned, the bike will survive the minus-40 temps if you’re careful with it. Most everything of critical importance is made of the same materials as used in automobiles, so there should be no more problems with the bike’s engine as there would be with a car’s. Just make sure you put stabilizer in the gas, prop the wheels off the ground and keep the battery on a trickle charger or Battery Tender.

The problems most likely to arise would be caused by you, not the bike. Aside from the aforementioned need to prep the bike if you intend to store it all winter, you also have to be careful how you handle it in sub-zero conditions. Starting the engine is the most potentially troublesome, as the oil will be like molasses and won’t want to circulate easily until the motor generates some heat. To help matters, use the lightest multi-grade oil recommended in the manual during the winter storage period.

Ideally, when starting the engine, you should remove the sparkplugs, reinsert them into their plug caps and ground the plugs on the cylinder head; then crank the engine over in several 5to 6-second spurts to get oil circulating before reinstalling the plugs and starting the engine. That can be a pain on these bikes, which have stick coils atop the plugs and engines hidden behind fairings and inner panels.

So if you choose not to do the plugremoval routine, make sure the engine runs as slowly as possible for a minute or so after it starts. And please do not sit on the seat when it’s 40 below; doing so will instantly crack the vinyl.

Don't get me started

QWhy do I need a compression release to help me start my 1976 Yamaha XT500 but not my 1974 Norton Commando?

Carrie Greenquist Posted on www.cycleworld.com

A Singles always tend to be

harder to start than comparably sized Twins and Multis. I realize that your Commando has more displacement (either 745cc if it’s a 750 or 828cc for the 850; you didn’t specify) than your 499cc Yamaha, but the factors at work are much the same.

For one thing, a Single only fires once every 720 degrees of crankshaft rotation, whereas your Twin does so every 360. This gives the Twin twice as many opportunities to have a combustion event that can help spin the motor over to the next possible combustion.

But if a Single doesn’t start on the first opportunity, it has to be spun through two complete crankshaft rotations before it again has a chance to fire.

That same factor also can have an effect on the kickstart ratio. For the aforementioned reason, a Single may need to be spun faster/farther per kick than a Twin in order to start, and that can increase the required effort the rider has to exert on the kick lever. What’s more, for any given engine size, it’s usually easier to push a kickstart lever through the compression cycles of two smaller cylinders than it is through that of one large cylinder.

Tool Time

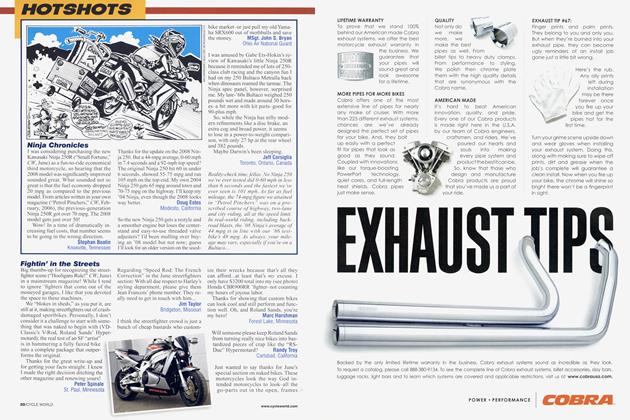

Recently, in preparation for our “Turn and Burn” cover story in the July issue, we needed to mount stickier tires on all 9 bikes. But three of those machines-the MV Agusta 312RR and two Ducati 1098sposed a problem: Each one secures its rear wheel to a single-sided swingarm with a huge, 55mm nut.

To begin with, it’s very difficult to find a socket of that size.

Just ask the Ducati shop that’s a few blocks from our office; despite being an authorized dealership, it has twice been incapable of removing a 1098 wheel.

Additionally, the wheel nuts have a 12-point design rather than a six-sided hex, and all of the socket-contact surfaces are very slightly tapered. If you stick a standard 12point socket on them, you’ll bugger the nut on your expensive steed.

We made a quick call to Former AMA Pro Thunder champ Jeff Nash, owner of Advanced Motorsports Ducati in Dallas, Texas, for his recommendation. He suggested the SpeedyMoto (www.speedymoto.com) Ducati 1098 Axle Tool (part # 04-203). The $69.95,12-point, Vz-inch-drive socket has the proper taper for both brands’ nuts (that’s just fun to say). It’s also very shallow, so virtually all of the force you apply to a breaker bar or torque wrench is transferred to the nut. With a conventional 55mm socket, which is much deeper than the SpeedyMoto unit, the breaker-bar/torquewrench’s attachment point is so far from the nut that the socket wants to tilt on its axis and slip off the tapered contact surfaces. The SpeedyMoto tool may be expensive, but we probably don’t need to tell you that spare parts for exotic Italian bikes aren’t cheap, either. -Blake Conner

Most riders who perform their own maintenance and repairs know that it’s always best to torque every fastener according to the manufacturer’s recommendations. But all too often, the little nuts, bolts and screws-the ones whose torque specs are in inch-pounds-get left out, usually because the rider either doesn’t have a torque wrench calibrated for such small settings or believes the tightness of those fasteners isn’t important.

Education is the answer for the latter condition, but Mac Tools (www.mactools. com) now has an excellent solution for the former one with its new 1A-inch Drive Torque Screwdrivers. The drivers come in two models: the $180 TSM16-88, with a torque range of 16 to 88 in.-lb.; and the $170 TSM4-22, with a 4-to-22-in.-lb. range. They have a traditional screwdriver shape machined from heavy steel and are adjusted by inserting a supplied 3/i6-inch Allen wrench into the rear of the handle. Turning the wrench shifts the “cursor,” as Mac calls the adjustable pointer, to the desired setting on the vernier scale in the window built into the handle. The tool then behaves like a traditional driver until the desired torque is reached, at which point an internal mechanism releases and prevents the application of any more torque. You can then turn the handle all day if you so desire without ever exceeding the preset torque.

What’s more, the drivers are equipped with a removable 1/4-inch-square-drive stud that plugs into a 1/4-inch hex socket, which is a standard size for most bit drivers, so you can plug in all kinds of tips (Torx, Phillips, PoziDriv, square, slotted) if necessary. And in case you need to torque a fastener that’s buried deep in a narrow opening that

you can’t get your hand into, the rear of the driver accepts a 1/4-inchdrive extension that allows you to turn it with a ratchet.

For sure, $170-$180 is rather expensive for what

seems like an elaborate screwdriver. But precision torque-setting tools of any kind never are cheap. And the end

result is far better than using the “that’s tight enough” approach.

-Paul Dean

Besides, if your XT500 is in the proper state of tune, you don’t need a compression release to actually start the engine; you use it to ease the task of getting the piston into the ideal position prior to kicking. For the engine to have the best chance of starting, the crankshaft must be spun fast enough to draw in adequate fuel for combustion and then have enough inertia not to immediately stop turning once the kick lever stops moving. This usually means the kick stroke has to begin as early as possible-which is with the piston just barely past TDC after the previous compression cycle. Using the compression release temporarily cracks the exhaust valve open, making it easier for the rider to push the piston through that compression stroke. Also, if the engine gets loaded up (the term used to describe

what happens when the engine ingests so much raw fuel that the sparkplug becomes wet and refuses to fire), opening the compression release allows the rider to easily kick the engine through numerous revolutions with the throttle wide-open, which helps dry the plug and evacuate excess fuel from the combustion chamber.

Raking the benefits

QI enjoyed the test you wrote comparing the Harley-Davidson Rocker to the Yamaha Star Raider (March, 2008), but one part of it confused me. You said that both bikes had raked-out steering heads, and that their forks had been angled even farther outward to reduce the front-wheel trail for better steering and handling. That seems backward to me. Wouldn’t raking the forks out even farther increase the trail?

Ed Whelen Dedham, Massachusetts

A No, I’m afraid it would not, and the accompanying illustration should help you understand why. Trail is calculated by drawing an imaginary centerline through the middle of the steering

head and extending it all the way down to the ground, then drawing another centerline, a perfectly vertical one that goes through the middle of the axle and also extends down to the ground. The distance between those two centerlines, measured right where they intersect the ground, is the trail. And as you can see, the vertical centerline that runs through the axle is behind the line that runs through the steering head. So if the fork tubes are raked out more than the steering head, the axle is moved forward, thereby shortening the trail.

A few chopper builders figured this out years ago. Producing bikes with the requisite look called for dramatically raked-out front ends, which they achieved by cutting off the steering head and welding it back on at a more radical angle-sometimes as much as 40 degrees or more. But that resulted in awkward, heavy-handling bikes with too much trail, which made the forks flop inward any time the front wheel wasn’t pointed straight ahead. The more-enlightened builders soon discovered that if they reduced the steeringhead angle by a few degrees and then raked the fork tubes outward a few degrees, their bikes ended up with the same look but with steering that was much more manageable. So in effect, all that Harley-Davidson and Yamaha have done with the Rocker and the Raider is take advantage of what chopper builders learned a long time ago.

Four-cylinder V-Twin

QMy 1989 Yamaha FJ 1200 has a Stage 1 jet kit and a Vance & Hines SSR2 slip-on muffler. Though the bike has 70,000 miles on the clock, it has new pistons and rings, and it runs very strong. Sometimes, though, when I am out on a ride, gasoline will start leaking from the carb hoses that are under the engine, and the bike sounds like a VTwin. After a few minutes, the problem goes away and the engine runs fine again. This only happens occasionally, not every time I ride the bike. Can you tell me why it does this? Dimitrios Frangakis Bayonne, New Jersey

AI believe I can. Based on your description of the symptoms, it would seem that either the float in one of the FJ’s carburetors sometimes sticks in the open position or a float needle fails to seal, allowing fuel to continue entering the float bowl to the point of overflow. When that occurs, some of the excess fuel is dumped onto the ground via that carb’s overflow tube while some of it gets into the engine, creating an excessively rich condition that temporarily fouls the sparkplug. The FJ’s four-cylinder engine then has a different sound because not all of its cylinders are firing. Subsequently, engine and/or road vibration causes the suspect float or needle to begin functioning once again, so fuel stops leaking through the overflow hoses, and the affected sparkplug dries out and resumes firing.

Feedback Loop

Ql find your Service column

interesting and informative, but I telt the need to comment on your review of Motion Pro’s ForkTru tool (May issue). A good piece of swag, no doubt, but you can perform the same sort of fork-tube alignment check with a flat piece of inch-wide bar stock 10 or 12 inches long, and use the $35 price of the ForkTru for, say, 4 or 5 six-packs of beer or maybe 10 gallons of gas. Also, a rough check of possible fork misalignment can be made by looking down on the top of the fender to see how it aligns with the front tire. Alan Delmartini San Luis Obispo, California

A Although I love tools, I too try to take advantage of any opportunity to perform a given task with a simple homemade device rather than one that must be purchased. In this case, however, using a piece of bar stock or making a visual observation is unlikely to align fork tubes with the same high degree of accuracy that’s possible with the ForkTru. Though I appreciate your input and thank you for providing it, a couple of the statements in your letter—“perform the same sort of fork-tube alignment” and make a "rough check”—indicate that you and I are not quite on the same page here.

Your methods can get the alignment in the ballpark but still involve some guesswork; the ForkTru takes guesswork out of the equation. For riders who want-or needoptimum front-suspension performance, precise fork-tube alignment is essential.

At the very least, you’ll need to remove and disassemble the carbs to determine which one is at fault and make the neces> sary repair. Considering the high mileage on your FJ, however, I suggest you instead do a complete rebuild on all four carbs.

Recall Roster

NHTSA Recall No. 08V115000 Kawasaki Ninja 250R Model year: 2008 Number of units involved: 1526 Problem: The front brake hose may be damaged over a long period of use. The hose tends to deflect forward during front suspension compression, allowing it to contact the edge of the front fork outer tube. Over time, this could damage the hose, causing brake fluid to leak, resulting in a lack of front-brake performance and increasing the risk of a crash. Remedy: Dealers will replace the frontbrake hose bracket. Owners not receiving this free remedy should contact Kawasaki at 866/802-9381.

NHTSA Recall No. 08V131000 Victory Vision Model year: 2008 Number of units involved: 1585 Problem: The electrical contact plate on the ignition switch base may not be properly secured to the ignition switch body, which can cause an unexpected loss of electrical power to the vehicle. A loss of electrical power could cause the vehicle to stall, increasing the risk of a loss of control and a vehicle crash. Remedy: Dealers will fully secure the ignition switch base to the switch body. Owners not receiving this free remedy should contact Polaris at 888/704-5290.

NHTSA Recall No. 08V145000 Triumph Rocket III Touring Model year: 2008 Number of units involved: 356 Problem: These motorcycles fail to comply with the requirements of Federal Motor Vehicle Safety Standard No. 120, “Tire Selection and Rims for Motor Vehicles other than Passenger Cars,” and Part 567, “Certification.” The certfication label on the left-front trame tube includes incorrect information regarding tire sizes and pressures, as well as an incorrect gross vehicle weight rating (GVWR). An owner may underinflate the front tire if using the incorrect information. Underinflation may cause a tire to slip or come off the rim, causing a loss of control which could result in a crash.

Remedy: Dealers will install a new certification label. Owners not receiving this free remedy should contact Triumph at 678/539-8782.

Candid Cameron

Qls fast there an internal-combustion an upper limit to how engine can turn? At just 3000 rpm, an engine is spinning at 50 revolutions per second, and it’s amazing to think that each piston is going up and down 50 times in the span of a single second. At the 16,000-rpm redline of a new GSXR600, that’s more than 266 up-and-down cycles every second, which is impossible for me to visualize in my head. What’s the record for the fastest rpm of any engine, racing or otherwise? Greg Jabín Del Mar, California

A Much of our amazement at things that move very fast comes from the weakness of our own structure-made of protein fibers and rather crumbly bones. People lose consciousness at accelerations of 8 or more times gravity and begin to fail structurally at maybe 26 g, when differences in the densities of internal organs begin to cause rupturing.

Machines, on the other hand, routinely operate at thousands of gs, and the great strength of their parts allows them to cycle (rotate, reciprocate, etc.) very rapidly. As an example, the peak piston acceleration in the current crop of mandated V-Eight Formula One engines is now around 10,000 g which means that parts change velocity at a rate of 320,000 feet per second, every second. These engines are now revving to above 20,000 rpm.

As early as 1964, Honda had explored high rpm in its four-stroke test engines running to 27,000. At present, there are two-stroke glow-plug model aircraft and tether-car engines running to at least 40,000 and perhaps higher. Really, the only limit to this is the length of time it takes to ignite and burn the fuel-air charge. In Honda’s research, the engineers found that the faster the engine turned, the more turbulent was its combustion, enabling flame speed to keep pace with rpm. Just as computer microprocessors have to be small because the speed of light sets a limit to their internal communication speed, so the speed of ignition and flame propagation tends to favor smaller cylinders. In F1 engines, ridiculously long ignition timings (up above 60 degrees BTDC) have been used. -Kevin Cameron

No motor promoter

QI applaud your efforts to educate and enlighten your readers on mechanical matters, but I urge you-and practically everyone else involved in the publishing of internal-combustion-related information-to cease your use of incorrect terminology. By this, I am referring to the continued treatment of the words “engine” and “motor” as though they were interchangeable. They are not. A motor converts a pre-processed source of energy, such as electricity, compressed air or pressurized liquid, into mechanical motion; an engine, including the internal-combustion variety, converts heat (through the burning of fuel-air mixture) into mechanical motion. You routinely take great pains to explain the details of all aspects of motorcycle function and design, yet you continue to misidentify the devices that propel these vehicles. Frank R. Warren

Tulsa, Oklahoma

Ain a purely technical sense, you are of course correct. But like the languages in which it exists, technical terminology changes over time, and “motor” for years has been a widely accepted word for describing an internal-combustion “engine.”

Besides, what is this publication all about? Motorcycles, not enginecycles.

And who produces them? Honda Motor Company, Suzuki Motor Corporation, Yamaha Motor Company, Harley-Davidson Motor Company, etc. Even in the automobile world, the products come from the likes of General Motors, Ford Motor Company, Toyota Motor Corporation, et aí. Racing that involves internal-combustion devices is called motorsports, even by the hallowed Society of Automotive Engineers. So, I’m sorry, Frank; I can’t agree with ya on this one. □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631 -0651 ; 3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Contact Us” button, select “CW Service” and enter your question.

Don’t write a 10-page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.