SERVICE

Paul Dean

Crossover conundrum

I own a 2002 H-D Softail Deuce with fuel-injection. I’m thinking about buying an aftermarket exhaust, and my question is whether or not a crossover tube is desirable on a 2-into-2 system. Some come with crossovers, most do not, but all new Harleys come with them from the factory. What are your recommendations? Stan Kolodny

Tucson, Arizona

The factory uses a crossover because it allows the exhaust pulses from each cylinder to have access to two mufflers instead of just one. This helps reduce the overall exhaust noise to EPA-mandated levels without the need for extremely large silencers. What’s more, because a crossover increases the exhaust system ’s internal volume, the system can more easily be tuned to help produce a broad powerband without sacrificing any peak power-something that is extremely difficult with two small, unconnected mufflers.

This is one of the major challenges faced by designers of big-inch, twincylinder engines-best evidenced, perhaps, by the hot-water-heater-sized single muffler on Yamaha’s I670cc Road Star Warrior V-Twin. The Harley Softails and Dynas fitted at the factory with a 2into-2 exhaust would never be able to get by with their disproportionately small mufflers if they didn’t have a crossover; they would either be too loud to pass federal noise standards or too restricted to make decent power-or both.

As far as I know, Vance & Hines is the only aftermarket exhaust manufacturer to offer a complete, 2-into-2 system with a crossover to fit post-2000 Harley Softails. And with one exception-D&D of Fort Worth, Texas-all of the slip-on mufflers for those Softails eliminate the stock crossover. You can buy slip-ons for H-D Dynas and FL touring models that retain the crossover, but not for Softails.

So, is a crossover desirable? It all depends upon what you’re hoping to achieve. But in the end, the performance provided by virtually all aftermarket exhausts is determined more by each system s basic configuration-and, of course, the state of tune of the particular engine to which it is attached-than it is by the presence or absence of a crossover. Besides, since only one aftermarket crossover system is available, your question is practically moot.

Then came Bronson

I have a 2003 Honda 750 Spirit. When at a slow idle or for about the first 15-20 minutes of riding, the lights brighten with a rev of the engine. But after about 20 minutes, everything seems to be fine. Could this be a battery, rectifier or other electrical problem? The bike is completely stock-no aftermarket lighting, gauges, etc. Any help you might offer would be great! Adrian Bronson

Ormond Beach, Florida

Based on your description of the condition, I have to conclude that there is at < least one weak cell in your Spirit’s battery. A weak cell won’t hold a full charge, so when the bike sits for a while, even overnight, the overall battery voltage gradually drops below normal. The battery still has enough oomph to start the engine, but the large momentary drain of starting, along with the voltage lost while the bike was sitting unused, causes the lights to be slightly dim at idle. At very low rpm, the alternator isn’t spinning fast enough to put much of a charge in the battery, so the lights aren 't as bright as they would normally be. But as soon as the engine rpm rises above idle, the alternator delivers enough current to the battery to allow the lights to illuminate at full strength.

Though lam fairly certain that the battery is at fault here, you should have it and the charging system checked by a competent technician to verify that the battery indeed is the problem. Checking the charging system involves a procedure that you probably do not have the equipment to handle, but testing the battery is much simpler. There are too many steps to fully explain here, but if you log onto www.yuasabatteries.com, you can view or download a complete tech manual that describes in detail-with illustrations and charts-how to check and test a motorcycle battery.

Tempest in a torque wrench

Thanks for your “Techtips” item in the December issue about sparkplug installation. I’ve had the problem of trying to remove “stuck” plugs from an aluminum head, and your tip to use anti-seize on the threads makes a lot of sense. A question, though: The Denso sparkplug website gives torque values very close to those in your article, but it also states that, “If threads are lubricated, the torque values should be reduced by approximately one-half to avoid overtightening.” Is anti-seize considered a “lubricant”? I torque just about every fastener, but with anti-seize, maybe I should use the finger-tight-plus-one-half-turn method rather than my torque wrench. Bill McElfish

Beaverton, Oregon

Based on the number of letters I’ve gotten on this subject, I apparently have stirred up a hornet’s nest of controversy, and there seems to be two schools of thought. One insists that the use of any kind of lubricant-and yes, anti-seize does fall into that category-on sparkplugs calls for a dramatic reduction in torque settings. The other faction is equally convinced that proper torque is proper torque, period. Their belief is rooted in the fact that there is no easy, accurate way of knowing exactly how much of the turning force applied to any given threaded fastener is dedicated to overcoming friction between the fastener and the threads in its mating hole. The amount of friction could vary

considerably, depending upon the cleanliness and general condition of the threads on both the fastener and the hole. So, if

you don’t know that value, they reason, how could you possibly know how far to reduce the torque? I’ve queried the tech people at several different sparkplug manufacturers on this matter, and all seem to agree that reducing the torque by one-half when using anti-seize is not a good idea. For one thing, half of the specified torque is not likely to sufficiently compress the crush washer when installing a new plug. And even when a used plug is reinstalled, one-half the recommended torque might not allow enough of the heat that the sparkplug absorbs to be transfered from the plug to the cylinder head. When that happens, the effective heat range of the plug is increased, just as it would be if you installed a hotter plug, and that could eventually lead to piston damage.

ToolTime

I have a philosophy about the tools I carry when riding off -road: No toolkit can be too light, and no tool can be too versatile. So when someone makes tools that are exceptionally lightweight and can perform more than one task, they’ve got my attention.

Evidently, the people at Motion Pro (www.motionpro.com) share that belief. The company has introduced a clever set of tire irons that not only weigh next to nothing, due to their forged-aluminum construction, but also serve multiple functions. One of the irons incorporates a six-point box wrench that fits a 12mm hex (for Japanese bikes) on one side and a 13mm hex (for European machines) if you flip the iron over. What’s more, the prying end of that iron has a little ridge molded into its tip that helps you gain purchase on the rim with less risk of pinching the tube. The other iron is available with a large hex in your choice of 22, 24, 27 or 32mm sizes to fit various axle nuts. You then can purchase a comparably sized aluminum adapter that plugs into the big hex, turning that iron into a breaker bar with a 3/s-inch square-drive male stud. The backside of the adapter also has a female receptacle that accepts 1/4-inch square-drive ratchets or extensions. The adapter even has a raised, serrated edge around its perimeter so that when it is unplugged from the tire iron, you can use it to spin loosened bolts and nuts on and off with your fingers.

That’s a whole lot of functions for three pieces that, combined, weigh less than 9 ounces. Plus, when the adapter is plugged into its tire iron, the 12/13mm hex of the other iron slips snugly over the adapter’s 3/8-drive stud, allowing you to “nest” the three tools into a compact, narrow stack that takes up little space in your toolkit.

Part numbers for two of these three pieces vary, depending upon the hex size selected. The tire irons list for $30 each and the adapter goes for $15. A tad pricey, but you

get your money’s worth in pure function and absolute “cool.”

Those techies suggest that when using anti-seize, reduce the torque to the lower end of the specified range. The recommended torque for a 14mm plug in an aluminum head, for example, is from 18 to 21.6 ft.-lb.; so, when anti-seize is on the threads, tighten the plug only to 18 ft.-lb. They also advise not to use regular oil on the threads, particularly if the plug will remain in the head for a fairly long period. Over time, the heat and pressure of combustion will gradually work its way up the threads and bake the oil into carbon. That could make the plug hard to remove, possibly enough so to bugger the threads in the head.

inside insight

I’d like to offer some insight into the origins of OEM dry weights, which, as has been previously discussed in Service, > always seem to be much lower than the bikes’ actual weights. I only ask that you not publish my name, my previous employer or my former job as an “insider” at one of the OEMs. > Here’s what they do: They take the design weight of each part of the motorcycle, add together the design weights of all those parts and voila ¡-they have a theoretical dry weight. Not only are fluids exempt, but the real-world production weight of each part is not calculated, either. That’s probably worth 5-8 percent right there.

FEEDBACK LOOP

1 have an easy solution for the onehose gas-pump issue discussed in the “Leftover combustibles” letter in the January issue of CW. Most gas pumps will still have the previous sale displayed when you ride up, so just divide the gallons shown on the readout into the sale amount, and the answer will tell you which octane fuel remains in the hose. By the way, there can be as much as .3-gallon of gas left in the hose. Adam Taylor

Phoenix, Arizona

What, we simultaneously have to buy gas and do math? Jeez, Adam, you’re asking an awful lot, aren’t you? Seriously, thanks for the tip. It answers one question, but it asks another:

What is your strategy if your arithmetic reveals that all of the hoses in that particular gas station are filled with regular?

Candid Cameron

We’ve all read about the 205-mph speeding ticket a fellow named Tilley got on a 2002 Honda RC51. On the CNN website, C W Editor Edwards was quoted as saying, “More likely, the cop with the stopwatch had an itchy trigger finger;” and “Tilley’s bike would have needed an addon turbocharger to go above 165 mph.” I don’t understand how Edwards of all people could believe that! My 2004 Honda CBR600F4Í will, according to your own tests, do 157 mph bone-stock. I also have ridden a 2001 Honda RC51 at 173 mph (verified by K-band radar), and it only has a Power Commander and a Titanium Sato Racing exhaust. I understand that you should not condone going over 200 mph on a public road, but I think you should at least acknowledge the fact that these bikes are capable of such speeds.

And about the guys at the salt flats: Be aware that cooler and thinner air will allow an engine to make more horsepower than it will in an arid region. Tony Johnson

Atlanta, Georgia

The rule of thumb is that for moderate changes in altitude, you lose 3 percent in atmospheric density’ for every 1000feet above sea level. Airplanes are able to go faster at high altitudes because air drag falls with atmospheric density’; but piston-powered aircraft that operate at high altitude are turbocharged to restore the power lost at altitude. This is not the case with an atmospheric-induction engine like that of the RC51; its power will drop in direct proportion to altitude, and the normal relationship of power to speed remains in force as it is at sea level.

Power to overcome aerodynamic drag rises as the cube of speed. Thus, for a 171-mph stock motorcycle (the measured top speed of the last RC51 we tested) to reach 205 mph would require a power increase of 80 percent, both speeds being reached at sea level. Aerodynamic drag does fall with altitude, so at 5000feet you might expect a 15 percent drag reduction to go with the engine’s 15 percent power loss. Since 15 percent is considerably smaller than 80 percent, 205 mph by a near-stock or mildly modified RC51 is not in the cards.

Kevin Cameron

My guess as to how all this got started? Ever since OEMs moved to an annual product-introduction cycle, they have to crank out new-model press specs very early-in August, for example, for motorcycles that won’t get built on a production line until November, December or later. What other choice do they have but to do it this way? All the Japanese OEMs do it; Em not sure about the others. With 20/20 hindsight, it would have been wise for them to call it something else, like “design weight,” but I suspect that the numbers were just passed along to the various press departments, where they were assumed to be “dry weights.” Once the numbers are in the public domain, it would look bad to go back and admit that any given bike actually weighs 10 percent more than first claimed.

So the gamesmanship goes on. Thank goodness we can rely on Cycle World to roll them onto a real scale!

Name and address withheld

Thank you for the most rational explanation of this long-standing mystery that I’ve ever heard. I’d not considered the long lead-time the manufacturers need to produce specifications for new models, but it makes perfect sense. Your explanation doesn’t render the grossly inaccurate weight figures any more palatable, but at least we now know why they exist. □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either; 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663;

2) fax it to Paul Dean at 949/631-0651;

3) e-mail it to CW1Dean@aol.com; or 4) log onto www.cycleworld.com, click on the “Letters to the Editor” button and enter your question. Don’t write a 10-page essay, but if you’re looking for help in solving a problem, do include enough information to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

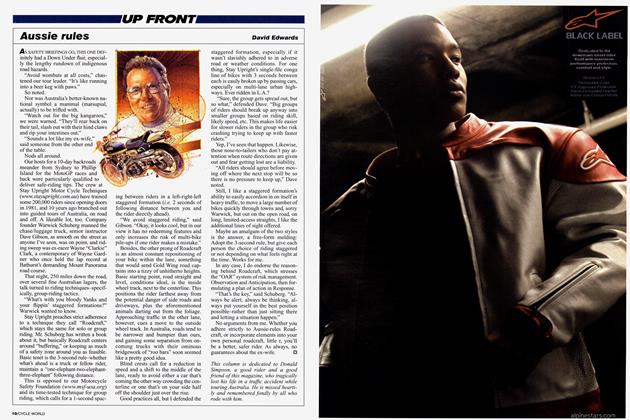

Up Front

Up FrontAussie Rules

March 2005 By David Edwards -

Leanings

LeaningsOn the Trail of the Mighty One

March 2005 By Peter Egan -

TDC

TDCTelephone Teams

March 2005 By Kevin Cameron -

Departments

DepartmentsHotshots

March 2005 -

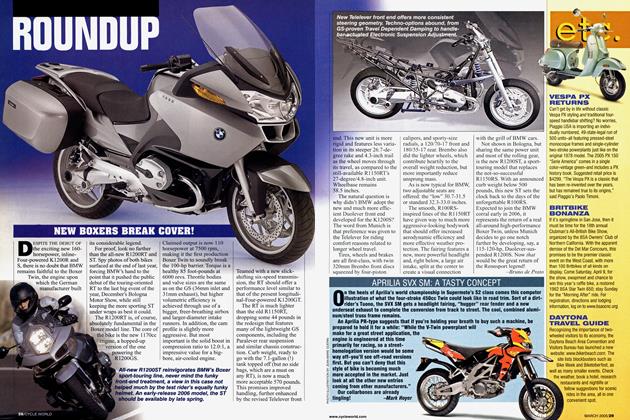

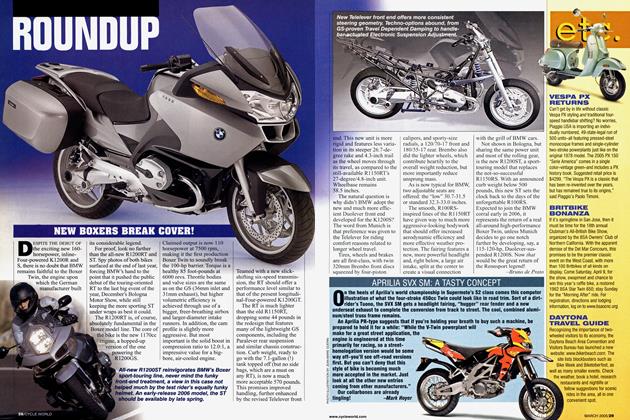

Roundup

RoundupNew Boxers Break Cover!

March 2005 By Bruno De Prato -

Roundup

RoundupAprilia Svx Sm: A Tasty Concept

March 2005 By Mark Hoyer