CHICA'S ALTERNATIVE UNIVERSE

If you come, he will build it

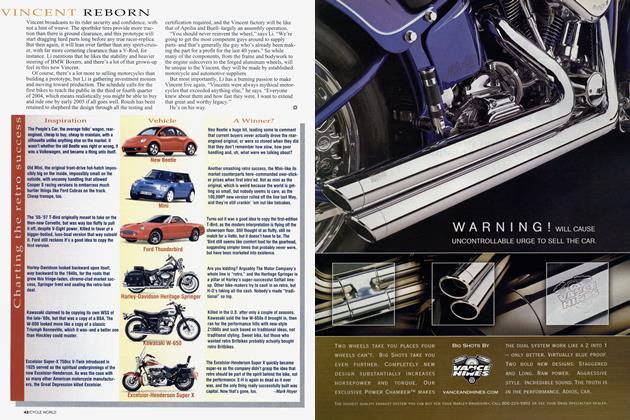

MORE THAN A DECADE AGO, CHICA WAS ROLLING ROCKA-billy-style through the streets of Kyoto, Japan. He was running a bike shop, but it was mostly doing repair work. He liked building complete customs even then, but he couldn’t find anybody who liked his retro style over there. His rockabilly vibe channeled via Japan and projected to Huntington Beach, California, has hit just the right note over here, though, and the old-style bobber/chopper thing is resonating in biker culture like nothing else.

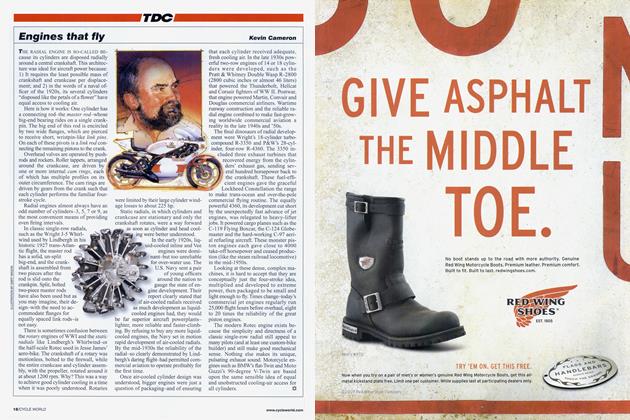

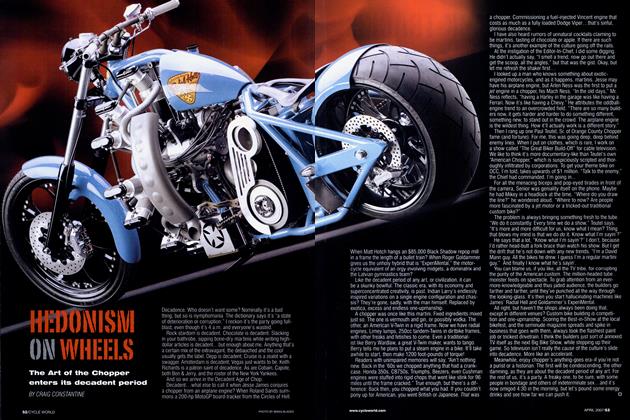

Okay, this clean little custom is not motor-vated by a radial engine, a two-stroke kart motor or a MotoGP racing fivecylinder. The bike is not steam-powered, and the closest you will get to a jet engine is a brass carburetor piece that hap-

pens to have the same name. Still, who builds a full-on custom using a Honda VTX 1300 V-Twin? It’s a middleweight cruiser. Fringed, fingerless-glove territory, queer (you know, odd...) looking chaps, bikes that are five years from milkcrate and bungee-cord duty.

But when a customer rolls up on a stock VTX and asks, “Can you customize this bike,” any creative businessman says yes.

“Then he started talking about crazy things,” says Chica. “‘Can you make it belt drive?’ I said yes, but of course it will cost a lot of money. ‘Can you make a frame?’ I said yes, but it will cost a lot.”

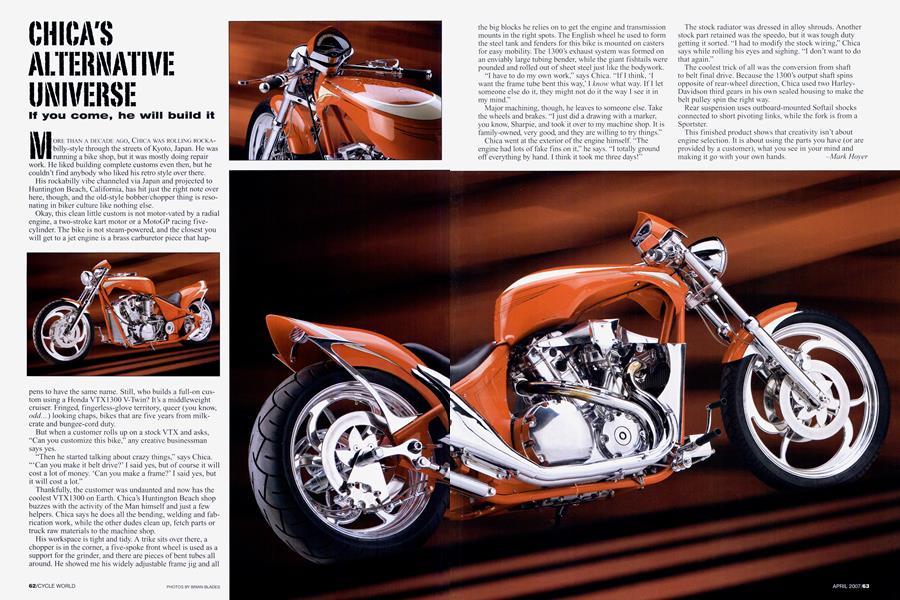

Thankfully, the customer was undaunted and now has the coolest VTX 1300 on Earth. Chica’s Huntington Beach shop buzzes with the activity of the Man himself and just a few helpers. Chica says he does all the bending, welding and fabrication work, while the other dudes clean up, fetch parts or truck raw materials to the machine shop.

His workspace is tight and tidy. A trike sits over there, a chopper is in the corner, a five-spoke front wheel is used as a support for the grinder, and there are pieces of bent tubes all around. He showed me his widely adjustable frame jig and all

the big blocks he relies on to get the engine and transmission mounts in the right spots. The English wheel he used to form the steel tank and fenders for this bike is mounted on casters for easy mobility. The 1300’s exhaust system was formed on an enviably large tubing bender, while the giant fishtails were pounded and rolled out of sheet steel just like the bodywork.

“I have to do my own work,” says Chica. “If I think, T want the frame tube bent this way,’ I know’ what way. If I let someone else do it, they might not do it the way I see it in my mind.”

Major machining, though, he leaves to someone else. Take the wheels and brakes. “I just did a drawing with a marker, you know, Sharpie, and took it over to my machine shop. It is family-owned, very good, and they are willing to try things.”

Chica went at the exterior of the engine himself. “The engine had lots of fake fins on it,” he says. “I totally ground off everything by hand. I think it took me three days!”

The stock radiator was dressed in alloy shrouds. Another stock part retained was the speedo, but it was tough duty getting it sorted. “I had to modify the stock wiring,” Chica says while rolling his eyes and sighing. “I don't want to do that again.”

The coolest trick of all was the conversion from shaft to belt final drive. Because the 1300’s output shaft spins opposite of rear-wheel direction, Chica used two HarleyDavidson third gears in his own sealed housing to make the belt pulley spin the right way.

Rear suspension uses outboard-mounted Softail shocks connected to short pivoting links, while the fork is from a Sportster.

This finished product shows that creativity isn't about engine selection. It is about using the parts you have (or are provided by a customer), what you see in your mind and making it go with your own hands. -Mark Hoyer