Engines that fly

TDC

Kevin Cameron

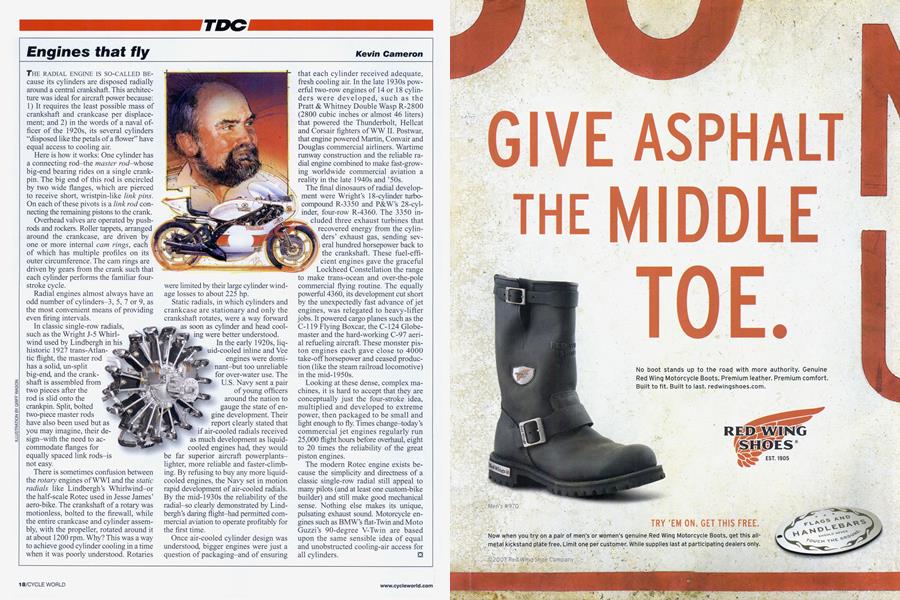

THE RADIAL ENGINE IS SO-CALLED BEcause its cylinders are disposed radially around a central crankshaft. This architecture was ideal for aircraft power because: 1) It requires the least possible mass of crankshaft and crankcase per displacement; and 2) in the words of a naval officer of the 1920s, its several cylinders “disposed like the petals of a flower” have equal access to cooling air.

Here is how it works: One cylinder has a connecting rod-the master rod-whose big-end bearing rides on a single crankpin. The big end of this rod is encircled by two wide flanges, which are pierced to receive short, wristpin-like link pins. On each of these pivots is a link rod connecting the remaining pistons to the crank.

Overhead valves are operated by pushrods and rockers. Roller tappets, arranged around the crankcase, are driven by one or more internal cam rings, each of which has multiple profiles on its outer circumference. The cam rings are driven by gears from the crank such that each cylinder performs the familiar fourstroke cycle.

Radial engines almost always have an odd number of cylinders-3, 5, 7 or 9, as the most convenient means of providing even firing intervals.

In classic single-row radiais, such as the Wright J-5 Whirlwind used by Lindbergh in his historic 1927 trans-Atlan-

tic flight, the master rod has a solid, un-split big-end, and the crankshaft is assembled from two pieces after the rod is slid onto the crankpin. Split, bolted two-piece master rods have also been used but as you may imagine, their design-with the need to accommodate flanges for equally spaced link rods-is not easy.

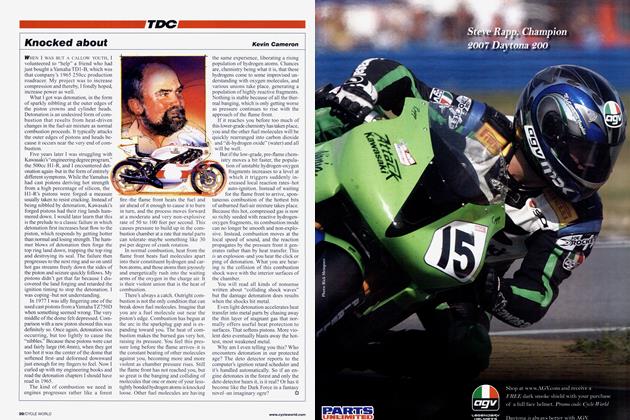

There is sometimes confusion between the rotary engines of WWI and the static radiais like Lindbergh’s Whirlwind-or the half-scale Rotee used in Jesse James’ aero-bike. The crankshaft of a rotary was motionless, bolted to the firewall, while the entire crankcase and cylinder assembly, with the propeller, rotated around it at about 1200 rpm. Why? This was a way to achieve good cylinder cooling in a time when it was poorly understood. Rotaries

were limited by their large cylinder windage losses to about 225 hp.

Static radiais, in which cylinders and crankcase are stationary and only the crankshaft rotates, were a way forward as soon as cylinder and head cooling were better understood.

In the early 1920s, liquid-cooled inline and Vee engines were dominant-but too unreliable for over-water use. The U.S. Navy sent a pair of young officers around the nation to gauge the state of engine development. Their report clearly stated that if air-cooled radiais received as much development as liquidcooled engines had, they would

be far superior aircraft powerplantslighter, more reliable and faster-climbing. By refusing to buy any more liquidcooled engines, the Navy set in motion rapid development of air-cooled radiais. By the mid-1930s the reliability of the radial-so clearly demonstrated by Lindbergh’s daring flight-had permitted commercial aviation to operate profitably for the first time.

Once air-cooled cylinder design was understood, bigger engines were just a question of packaging-and of ensuring

that each cylinder received adequate, fresh cooling air. In the late 1930s powerful two-row engines of 14 or 18 cylinders were developed, such as the Pratt & Whitney Double Wasp R-2800 (2800 cubic inches or almost 46 liters) that powered the Thunderbolt, Hellcat and Corsair fighters of WW II. Postwar, that engine powered Martin, Convair and Douglas commercial airliners. Wartime runway construction and the reliable radial engine combined to make fast-growing worldwide commercial aviation a reality in the late 1940s and ’50s.

The final dinosaurs of radial development were Wright’s 18-cylinder turbocompound R-3350 and P&W’s 28-cylinder, four-row R-4360. The 3350 included three exhaust turbines that recovered energy from the cylinders’ exhaust gas, sending several hundred horsepower back to the crankshaft. These fuel-efficient engines gave the graceful Lockheed Constellation the range to make trans-ocean and over-the-pole commercial flying routine. The equally powerful 4360, its development cut short by the unexpectedly fast advance of jet engines, was relegated to heavy-lifter jobs. It powered cargo planes such as the C-119 Flying Boxcar, the C-124 Globemaster and the hard-working C-97 aerial refueling aircraft. These monster piston engines each gave close to 4000 take-off horsepower and ceased production (like the steam railroad locomotive) in the mid-1950s.

Looking at these dense, complex machines, it is hard to accept that they are conceptually just the four-stroke idea, multiplied and developed to extreme power, then packaged to be small and light enough to fly. Times change-today’s commercial jet engines regularly run 25,000 flight hours before overhaul, eight to 20 times the reliability of the great piston engines.

The modern Rotee engine exists because the simplicity and directness of a classic single-row radial still appeal to many pilots (and at least one custom-bike builder) and still make good mechanical sense. Nothing else makes its unique, pulsating exhaust sound. Motorcycle engines such as BMW’s flat-Twin and Moto Guzzi’s 90-degree V-Twin are based upon the same sensible idea of equal and unobstructed cooling-air access for all cylinders. U

View Full Issue

View Full Issue