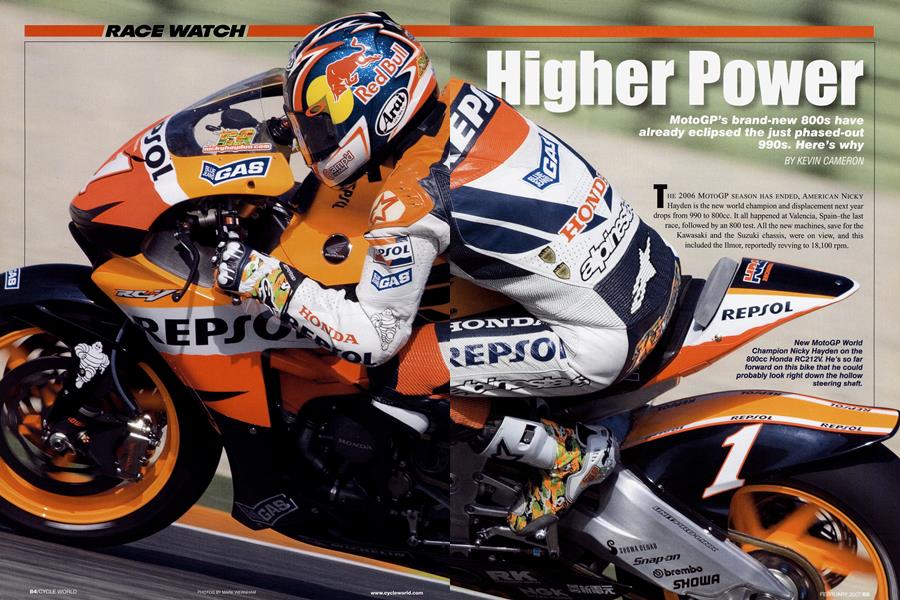

RACE WATCH

Higher Power

MotoGP's brand-new BOOs have already eclipsed the just phased-out 990s Here's why

KEVIN CAMERON

THE 2006 MOTOGP SEASON HAS ENDED, AMERICAN NICKY Hayden is the new world champion and displacement next year drops from 990 to 800cc. It all happened at Valencia, Spain—the last race, followed by an 800 test. All the new machines, save for the Kawasaki and the Suzuki chassis, were on view, and this included the Ilmor, reportedly revving to 18,100 rpm. Another before-the-fact theory has been that 800s, being smaller, will have to be more highly tuned to achieve their power. This will make their torque curves steep as the Matterhorn and this, glory be, will bring back racing made exciting by highside crashes. Steep torque? Hayden, in an impromptu 8-minute post-800-test press conference, told us that the new Honda engine is much smoother and that he can therefore get the power on earlier. Preliminary tire results indicate tires are lasting longer and gripping better. Golly, folks, looks as if the “exciting crash theory” is bunk. The manufacturers, having learned that it’s easier to go fast with smooth power than with big, spiky numbers, are not going to go back to the old way to please the romantics or the ambulance-chasers among us. The noise! Two years ago, marketeers ended MotoGP sound limits in the interest of auditory spectacle. As veteran tuner Erv Kanemoto observed, “Now you need something like a phone booth just to hear your (two-way) radio!” Some teams do have plastic-fronted booths equipped with monitors on pit wall. Everyone wears hearing protectors, and one insider joked that a class-action workenvironment suit by team personnel would succeed in any court. The sound hurts, and the unprotected go home with splitting headaches. I can stand 125s and 250s, but open four-stroke megaphones deliver jack-hammer blasts that my inner ear can’t take. No wonder Valentino Rossi has mufflers on his Yamahas. I listened to both the 990 and 800 Yamaha Fours, finding also something melodie and familiar in their sound. It was the sound of a Triple. How? Maybe, as some propose, two cylinders fire together, then the two others at close intervals. These firing clusters are hard on the driveline-I watched mechanics carrying new primary gears into the garages. Replace every day to keep failure at bay. Another consequence of the fuel reduction affects how traction control is implemented, and there is also the “Ducati factor.” Ducati has forcefully pursued horsepower in winning races and, while it has not been as successful as Honda and Yamaha, its wins have shaken up the establishment. That has forced everyone to increase power, and the harder you try to make power, the harder it becomes to use that power-with bumps and dips in the torque curve that threaten to break tire grip as the rider accelerates off turns. Sunday’s GP, but it became much more visible during the 800 test several days later. Headers are joined in pairs and the two pipes terminate on the right. As with most bikes today, the front of the “tank” has no fuel in it. Under the first cover is a tray of electronics and beneath that is the airbox. The actual fuel is in the quickly removable seat/tank unit, held to the main spars by four cam fasteners. Once that unit is removed, the cambox of the rear cylinder pair can be seen. If you’d hoped for way-rad linkage hubcenter Buck Rogers front-end design, forget it. The Ilmor is conventional, with latetype Öhlins fork, Michelin tires and a normal swingarm. Why does F-l engine wizard Mario Ilien want to play the twowheel game? I wish I knew, but I’m glad he’s playing it. The new Yamaha 800s, in black, unpainted carbon, look just like the 990s. They are the most pared-down, light-appearing bikes of the bunch, continuing the habit of the Ml of being right on the weight limit. The swingarm is braced on its underside and there are large, curvy outlets for hot radiator outlet air. Over the years, the 990’s head has grown taller, indicating use of progressively longer valves to allow more-streamlined ports. Bore and stroke have been changed repeatedly in seeking more power from higher revs and more valve area. Like any Superbike, this inline-Four has a 4-2-1 pipe that smoothes torque delivery by filling in the classic 4-into-l torque dip. Kawasaki’s 990cc ZXRR also wore a 4-2-1. So far, everyone’s 800 has four cylinders. Horsepower is a contest of compromise. Big bore for high revs and valve area? Or smaller bore for improved combustion and acceleration across the band? Pushing revs, pushing peak parts’ accelerations, means stressing pistons until they crack early, hammering valves until cam lobes and tappets score and flake. Get the numbers and the testing right, then maintain absolute quality control, and you may have fast bikes that run like airliners-every perfect part replaced on a no-exceptions schedule before its propagating internal cracks reach the surface. Small mistakes mean embarrassing, smoky DNFs. Timed-out parts look perfect but are internally laced with failure.

CONTINUED Why reduce displacement from 990 to 800? The perpetual theme of sanctioning bodies is that slower speeds must make racing safer. Yet even bicyclists wear helmets. As the Ilmor, running in Sunday’s GP as it did in the previous round in Portugal, came past the media center at 183 mph, journalist Michael Scott exclaimed, “Why, anyone can see that bike is much safer than the others.” And so the new 800s have become the “safety bikes.”

Ducati’s Loris Capirossi set fastest lap on race tires in the GP at 1:32.924. But on the following Thursday two riders on the new “safety” 800s lapped even faster-Dani Pedrosa on the new Honda RC212V at 1:32.66 and Chris Vermeulen on a hybrid Suzuki (a new 800 V-Four in a 2006 990 chassis) at 1:32.69. Several others were close behind. How about top speeds? The Ducatis were fastest; riders

Stoner and Capirossi on new 800s equaled the straightaway speed of backin-MotoGP Alex Barros on the Pramac Ducati 990. The 800’s sound is similar but a note higher, indicating perhaps 2000 extra revs.

Another theme of displacement reduction is that it will somehow save the teams money. Suzuki technical director Stuart Shenton quipped, “They cut the displacement 20 percent then the engineers get the power back by revving up the engines. With the same power as before, they lap just as fast, but with the engines turning higher they wear out quicker, so they cost more to run.”

At the rate of development we’ve seen in this four-stroke era, the idea that these new 800s should already be this fast is not so strange. Much has been learned about how to make chassis hook up on bumpy surfaces. More has been learned about how to smooth engine power delivery so that riders can use it more of the time. Not every discovery has been

fully implemented on the 990s because big mid-season or inter-season changes are risky. But if you’re starting over with a whole new design, you will use all you’ve learned. This is what I think we were seeing in the Valencia 800 test.

There’s information in that sound. No more the musical blare of the classic 1960s, when accelerating bikes played a scale of ascending overtones on their long, open megaphones. We dance to a different tune today-one that is harsh and unmusical for good reason.

As a tire works at its limit of grip, fresh footprint is laid down at the leading edge with zero stress, which means it also makes zero contribution to grip. Stress increases on a “pixel” of footprint as the tire rolls over it, and at some point on its trip to the rear of the footprint it begins to slide. At the trailing edge of the footprint, it is sliding so much that again, its contribution to grip is small. What this means is that grip at leading and trailing edges is small, increasing in some fashion toward a maximum in a middle region. The average of zero and maximum is about half of maximum. This is normal tire grip, and we ought to be dissatisfied with it. Why can’t we make the whole footprint work equally hard?

Turns out we can-or at least we can get a lot closer. The way it is done in MotoGP is by delivering engine power

in pulses rather than smoothly. The tire rolls forward just enough to lay down a fresh footprint, then a cluster of engine cylinder firings is delivered to it. Because this fresh footprint is not sliding, those power impulses have as hard a job to break tire grip as does a group of men trying to get a heavy crate moving across the shop floor. Static friction is always greater than sliding friction.

And so all engines in MotoGP today fire their cylinders in clusters, giving them the rough, deeper sound we hear. The firing cluster generally takes 180 degrees or so-with longer periods of no firing between, during which the tire can lay down a fresh minimum-stress footprint, ready for the next yank.

CONTINUED

Racing V-Fours sound like rock-crushers at low revs-rough and harsh-and the 990 V-Five Hondas are similar. At idle, the Ducatis sound like old John Deere tractors-a series of sound bursts without smoothness. When they run down the straight, they generate a heavy, breathy undertone. I suspect this is the once-percycle cluster of cylinder firings. Superimposed on this is the scream of high rpm. Those of us who have heard the 1960s megaphone music may pine for what’s lost, but serious traction is gained in return. Kawasaki, previously getting nowhere in MotoGP, changed to an “ugly” firing order-and was promptly competitive. The tire companies deny all knowledge of how-or indeed, whether-this works as claimed.

MotoGP’s first big problem in 2002 was engine-braking. Engine friction is typically 15 percent of power, so when a rider closed the throttle on a 220-hp engine at peak revs, suddenly the rear wheel had to provide traction to overcome 33 hp of engine friction. But when you brake, weight transfers to the front wheel, leaving the rear wheel light or even hovering. The result was sudden rear slide-outs on corner entry-or even worse, rapid buildup of rear-wheel oscillations that threw riders on the ground. Traditional slipper clutches, because they must operate through the gearbox, work best in one gear and less well in the others. Slippers were okay on heavy Superbikes, less so on carbonbrake-equipped MotoGP bikes. Yamaha, Suzuki and later Ducati experimented with computer-controlled hydraulic clutches that resembled Marelli’s “Selespeed” automated clutching/shifting system for cars, but the pace of affairs outran their development.

So long as the fuel allowance was 24 liters (6.3 gallons), a better response was to allow the computer to open the throttle just enough on deceleration to overcome most engine friction. The result was engines that could be heard to run all the way to the throttle-up point in turns.

Then capacity was cut to 22 liters, and the extra fuel required for full comer-entry friction cancellation could no longer be afforded. At Laguna Seca and Valencia, I heard the normal sound of four-stroke engines on overmn-popping, banging and cackling-but only while the machine remained upright. As bikes angled over, the banging gradually ceased and was replaced by smooth running to the apex. When I asked Jeremy Burgess, Rossi’s engineer, about this, he replied that friction cancellation must now be applied only as needed. The more the machine leans over, the more it needs protection.

“How can there be time to get that all just right?” I asked him. He replied that the brighter the rider, the more quickly he can figure out and dial-in such systems. This makes it appear that at least one lean-angle-sensitive system is now in widespread use in MotoGP. No wonder the bikes are so crawling with wiring and mil-spec connectors. They have so many sensors and devices, such as Inertial Reference Units, that they are coming to resemble the nervous systems of simple animals! Somewhere an engineer is working on the problem of how, by analogy with living organisms, to make such systems self-training.

In the past, engine torque was smoothed by altering ignition and fueling maps at trackside (passive smoothing) and by use of electronic ignition retard whenever wheelspin was detected (active smoothing). But such methods waste fuel by operating at less-than-optimum timing. Better to limit how much power you make in the first place. This has led to Honda’s differential throttle and to split throttle-control schemes on other makes. If spin is detected as the machine accelerates, the engine-management computer either unwinds some of the throttle the rider has applied (Honda) or begins to close the set of throttle butterflies (usually two out of four) that it controls.

For 2007, the 800s we saw at Valencia must make do with 21 liters of fuel (5.5 gallons), so more compromises are necessary. Want to rev your engine up to make a bunch of power? The appropriate longer valve timing will waste fuel during overlap (intakes and exhausts both slightly open around TDC at the end of the exhaust stroke) any time the engine operates at lower revs. That might tempt Ducati to revive its “freewheel” cornerentry scheme, in which the engine is automatically declutched and idled during braking. While that might save fuel, it would also eat up development time and money. But if a team concentrates on just smoothing engine torque, it may lack the power to lead at faster tracks. In this game, there is no “just goin’ for it.” Success rewards the best overall setup.

Engineering isn’t the only place for compromise. One team may see rev limiters as a key to improving its position with respect to Ducati (desmo valve operation) and Suzuki (pneumatic valves), both of whom can potentially reach higher revs-and therefore higher power-than those who choose metal valve springs (rapidly becoming an oxymoron). Now imagine the pre-committee maneuverings, as one team proposes a ban on desmo as a means of motivating Ducati support for a ban on rev limiters. Lobbyists! Secret agents! Compromising situations!

Ilmor chose to run its new V-Four in

CONTINUED

Starting is motorhead theater. First, a coolant pre-heater is hooked into two points, just as in Formula One. The small crank-bearing clearances required for successful use of the watery, low-friction oil mean that when the engine is cold there is too little clearance for safe operation (aluminum expands about three times more than steel). Preheating sees to it that these bearings operate always in a band of about 15 degrees Celsius, maintaining designed clearances. A data cable plugs into a connector to the left of the steering head, allowing not only the usual access to data and maps, but also monitoring of any critical variables during startup. A pressure bottle is also plugged in briefly to charge the pneumatic valve system.

Once all is green, the external starter is plugged into the internal spline of the left end of the jackshaft running across the engine’s Vee. The engine is turned and starts immediately, running at such a high idle that you feel the throttle must be stuck. This is also the case with the pneumaticvalve Suzukis. Pneumatic springs provide extra pressure over the nose of the cam, combined with moderate seat pressure, so it takes speed to keep the tappets from breaking through the watery oil film on the cam lobes-the boat must go fast enough to keep the water-skier from sinking.

The new Honda RC212V is also a VFour. As many have noted, the original RC211 V-Five was just a developed VFour RC45 Superbike engine with an added cylinder, so here we are, back again. Final versions of the RC45 had crank endfeed oiling. Because this system doesn’t have to fight centrifugal force to get oil to the crankpins, it works well with minimal oil pressure.

Another late ’45 feature was crankcase evacuation combined with low-pressure, low-friction oil scraper rings on the pistons-saving several hp. Yamaha treated the press to the “Evolution of the Ml Engine” in its hospitality. All six beautiful, milled-from-solid engines displayed, from 2002 to present, had large breather lines to pull crankcase pressure down by feeding it into the exhaust pipes. Hmm.

Instead of the three megaphones of the V-Five, the new RC212V has two. The seatback is sensibly bobbed off. First, seatbacks are just decoration, for they are in separated airflow. If this were not the case, why was Rossi raising his back on the straight? And second, no one starts bikes by pushing on the seatback any more. The Ilmor and Suzuki have plug-in starters, the Ducati and Honda use Superbike-style rear-wheel start-carts, and Yamaha has its flat starter, onto whose two bi-conical rollers the bike is backed. As with the RC211V, the Honda’s fuel is carried in a tank that is visible projecting rearward under the seat-another attempt to centralize mass to speed maneuverability.

As the Ducatis warm up, each movement of the throttle produces a shot-like report from the megs. The 990cc V-Four D16 had two megs under the seat and two out the right side, low. On the 800, headers are paired, then served by a single meg each. Either way, LOUD. Even their startcarts are loud! As with most MotoGP bikes, the swingarm pivot is only about 2 inches to the rear of the wheelbase midpoint, making the arm about 26 inches long. That’s a big change from the 19-inch arm on the 916.

Why does Yamaha continue with an inline-Four when narrow V-Fours are the choice of Honda, Suzuki and Ilmor? An inline is the easiest way to concentrate engine mass forward, keeping the front tire loaded even when accelerating off lower-gear comers. The others have had trouble here. Honda moved its entire front end forward and partially stacked its gearbox shafts to achieve similar effects. Ducati’s engine is now so far forward that there is sometimes tire mbber on the front bank’s valve cover. Is the Yamaha wide? Measure the distance across your knees on a small motorcycle and compare it with the 14.5inch width of the 990 Yam’s cylinder head. The 800 will be narrower-width is not a problem. Pick an architecture and build on what you know.

CONTINUED

Electronics continues to be central, civilizing powerbands as engines are pushed toward higher powers. Get on the tightrope traction limit and stay there, perfectly balanced. Don’t go for goals you cannot afford. Fix the problems holding back your riders today while R&D tackles the next layer.

Where are the new bikes fast?

Elay den reckoned it wasn’t top speed, so they must be cornering faster. This fits with the idea that tires are working better on these machines. How long before officialdom begins to call for performance-reducing grooved tires like those mandated in F-l, to save MotoGP riders from the new speed of these reduced-displacement 800s? □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontBike of the Year, 2006

FEBRUARY 2007 By David Edwards -

Leanings

LeaningsFlying On the Ground

FEBRUARY 2007 By Peter Egan -

TDC

TDCMixing It

FEBRUARY 2007 By Kevin Cameron -

Departments

DepartmentsHotshots

FEBRUARY 2007 -

Roundup

RoundupItaly Rocks!

FEBRUARY 2007 By Bruno De Prato -

Roundup

RoundupTen-Nine-Eight...Wow!

FEBRUARY 2007 By Bruno De Prato