TEMPERATURE AND FAILURE

IGNITION

TDC

FROM THE STEAM ERA UNTIL TODAY, THEY’RE STILL RELATED

KEVIN CAMERON

Motorcycle engines have cooling systems to keep critical parts from becoming hot enough to lose their properties and fail. Back in the Age of Steam, one of the most feared results was crown sheet failure. The crown sheet was the arched steel top of the firebox. Below the sheet was the intense, forced-draft coal fire, and above it (normally) was boiler water. Under pressure, boiler water was at a steady several hundred degrees, but even such hot water easily kept the crown sheet cool enough to retain adequate strength, especially since it was supported from above by numerous stay bolts. An alert engine crew monitored water level diligently.

If for any reason the water level fell near the crown sheet, solid coverage became episodic sloshing, and crown sheet temperature rose. If this continued, the crown sheet could soften, slowly deform, and then tear open, turning the boiler into a violent, fastaccelerating steam rocket, blowing it off the frame and catapulting it forward, sometimes coming to rest a quarter mile or more ahead of the train.

If a World War II B-29 bomber suffered an in-flight engine fire and fire bottles failed to contain it, the crew had 30 to 60 seconds to bail out before the flame broke through the thin stainless-steel firewall to play against the 2024 aluminum main wing spar. With aluminum alloys, significant loss of strength begins at just above boiling water temperature, 212 degrees Fahrenheit. The aluminum did not have to come even close to its melting point to fail by buckling, causing the aircraft to roll toward the failed side and enter a spin.

For the supersonic Concorde aircraft, which cruised at 1,330 mph, aerodynamic heating (air friction) required an aluminum airframe material having

high hot strength—a “Y-alloy” closely related to the cylinder head material in countless high-performance aircooled motorcycle engines. In this material, added nickel and copper form a hard intermetallic phase that retains strength at higher temperatures than conventional high-strength alloys, such as 7075. Right on the drawing for the heads of the legendary Vincent V-twin motorcycle it says, “Material: Y-alloy.”

Even when heat-tolerant alloys are used, exposure to higher-than-planned temperature allows the part to slowly yield to stress in a process called “creep.” Pressed-in valve-seat rings loosen; valve seats deform to become oval or to slowly move off center. Then the valve no longer makes large-area contact with its seat but touches it at only one or two points, losing most of its cooling. It grows hotter as hot exhaust gas leaks past it. The valve overheats and fails. This was common in military aircraft engines, but it is also not unheard of in air-cooled production motorcycle engines subjected to heavyduty use. Traditional motorcycle engines were designed by experience, so their cooling fin area was made adequate for the highway speeds of their time. Vintage machine owners who insist upon moving with freeway traffic can easily encounter head warping, unseated valves, and valve failure from over-temperature.

Classic air-cooled designs that remain in production today, such as HarleyDavidson V-twins and BMW flat-twins, now require “strategic cooling” to prevent the above maladies. Pumped oil or water is circulated through passages behind exhaust valve-seat areas to control their temperature.

When exhaust valves make full contact with their seats, modern valve materials are adequate for reliable function. As with temperature-tolerant aluminum alloys, valve steels benefit from the precipitation of super-hard

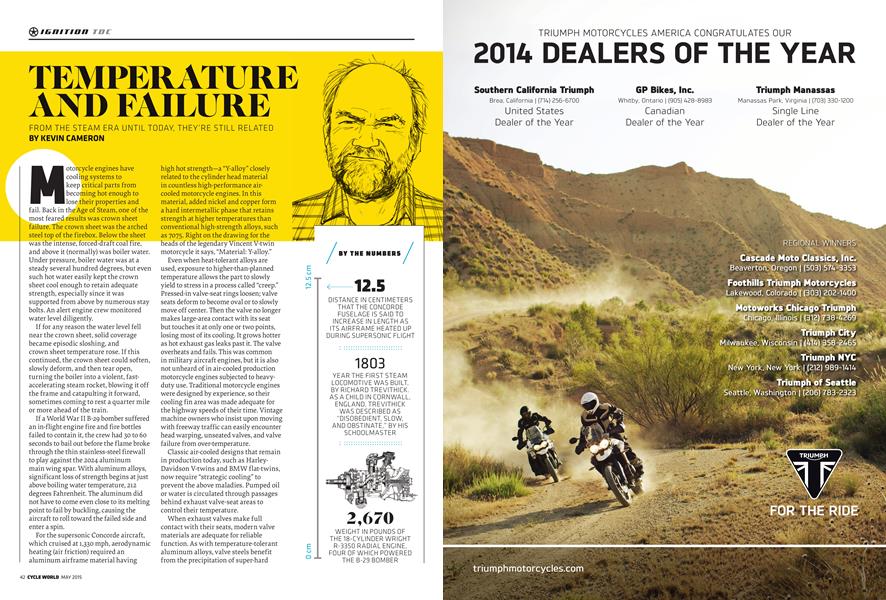

BY THE NUMBERS

12.5 DISTANCE IN CENTIMETERS THAT THE CONCORDE FUSELAGE IS SAID TO INCREASE IN LENGTH AS ITS AIRFRAME HEATED UP DURING SUPERSONIC FLIGHT

1803 YEAR THE FIRST STEAM LOCOMOTIVE WAS BUILT, BY RICHARD TREVITHICI. AS A CHILD IN CORNWALL, ENGLAND, TREVITHICK WAS DESCRIBED AS `DISOBEDIENT, SLOW, AND OBSTINATE," BY HIS SCHOOLMASTER

2,670 WEIGHT IN POUNDS OF THE 18-CYLINDER WRIGHT R-3350 RADIAL ENGINE, FOUR OF WHICH POWERED THE B-29 BOMBER

phases within the material.

The motorcycle engine part that must tolerate the most destructive combination of extreme stress and temperature is the piston. The crown of the piston is exposed to the full fury of combustion, while the piston as a whole must withstand top dead center reversal stresses from thousands of times the acceleration of gravity. Even when made from modern developments of the original Y-alloy, pistons are vulnerable to any change in their operating parameters. Even a 5-degree Celsius rise in average temperature can cause a previously reliable piston design to fatigue crack and fail prematurely.

Tensile and bending stress on pistons increases as the square of rpm, so if development succeeds in finding 5 extra horsepower at a cost of raising peak power rpm by 250, that too can make a

previously reliable piston design old before its time.

Metals are a jumble of tiny crystals (sometimes referred to as grains), each one internally imperfect, joined together by chaotic inter-granular regions. Although metals can attain incredible strengths, we can understand why the late John Britten once said, “After working with directional materials (carbon fibers consisting of near-perfect crystals), I’ve become suspicious of metals and regard them as something like very tightly packed sand.”

In an ideal material, all atom-to-atom bonds would be identical, carrying equal shares of applied stress. But in real metals—especially in their intergranular zones—atom-to-atom spacing varies, with stretched inter-atomic bonds carrying more stress and less-stretched ones carrying less. When we say a part

is at 375 degrees Fahrenheit, that number is only an average, while individual thermally vibrating atoms may from moment to moment have more or less than the average energy. Maybe enough more—if its bonds to neighboring atoms are under great strain—to break those bonds. Raising the average energy of the part (its temperature) even a little bit makes such bond breaking more likely. This process leads by degrees to actual cracking.

Metallurgists seek to strengthen metals and equalize the stresses carried by all atomic bonds. Designers use dynamic Finite Element Analysis to reveal the pattern of stresses that results during piston reversal at TDC and then seek shapes that can reduce any concentrations of stress. Cooling oil jets are directed at the undersides of piston domes. Progress is achieved but gradually. CUM

“AFTER

WORKING

WITH

DIRECTIONAL MATERIALS (CARBON FIBERS CONSISTING OF NEARPERFECT CRYSTALS), I’VE BECOME SUSPICIOUS OF METALS AND REGARD THEMAS SOMETHING LIKE VERY TIGHTLY PACKED SAND.”

-JOHN BRITTEN

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Third Dimension

May 2015 By Mark Hoyer -

Intake

IntakeIntake

May 2015 -

Ignition

IgnitionTo Infinity And Beyond

May 2015 By Blake Conner -

Ignition

IgnitionKenji Ekuan, 1929-2015

May 2015 By Kevin Cameron -

Ignition

IgnitionCw 25 Years Ago

May 2015 By Blake Conner -

Ignition

IgnitionOn the Record Abe Askenazi

May 2015 By Brian Catterson