Faster chatter

TDC

Kevin Cameron

FRONT-END CHATTER IS SOMETHING OF which road riders fortunately have little experience. Chatter occurs under conditions of hard cornering and is a rapid, shuddering vertical vibration of tire against pavement. Chatter—especially at the front—is all in a day’s work for the hardest-riding sportbikers, track-day regulars and competition riders. As exracer Mick Grant once succinctly put it, “Chatter is most likely under conditions of heavy load and good grip.” As a motorcycle enters a turn, its deceleration transfers weight to its front wheel, supplying the first condition. The second condition arises from high-grip rubber and good pavement. Chatter begins with a disturbance to grip-a bump or two will do-and then builds up into a highfrequency vibration. The driving force of chatter is a rapid release-and-grip cycle at the tire footprint, exciting the tire’s natural vertical bounce frequency. At the front, if the natural foreand-aft bending frequency of the fork is close to this frequency, a resonance can develop that builds up the tire bounce to a disturbing amplitude.

The energy that induces chatter is taken from the sideways motion of the tire as it slides, then grips. The front tire’s side grip is trying to turn the bike, but when it is partly released at each chatter cycle, it slips sideways, toward the outside of the turn, thereby acquiring kinetic energy. The farther it slides, the more energy it accumulates, and when the tire hooks up, this kinetic energy compresses it more, causing it to bounce up higher as the chatter cycle repeats.

Some speak of “riding through” chatter, but this does not mean ignoring chatter and gassing it up regardless; this is often impossible because the harder the rider accelerates, the harder the front tire chatters, drifting the front wheel to the outside. Riding through chatter really means finding ways to outwit it. Sometimes changing line in a corner forces the chatter to start over, thus controlling its intensity. Other riders speak of trying different parts of the tire by hanging off more or less-perhaps finding a band of tread less subject to dreaded chatter.

Two popular engineering strategies exist for suppressing chatter. One is to separate or detune the oscillations that contribute to chatter; that is, the tire’s vertical bounce frequency and the foreand-aft vibratory whip of the fork. The other is to bleed (damp) energy out of the chatter cycle faster than it is generated.

The first strategy lies behind the decadelong switch from female-slider front ends to male-slider or “upside-down” design. This sharply raises the natural flexural frequency of the fork by placing the largerdiameter tubes at the top, where their greater stiffness better resists bending forces applied by the tire. With the tire’s bounce frequency still in the vicinity of 22 cycles per second, but that of the fork raised to a significantly higher number, the two can no longer come into resonance to cooperatively produce severe chatter.

The second strategy depends upon either the tire’s natural damping ability or on the ability of fork dampers to function at the high frequency of chatter. Most fork dampers operate at atmospheric pressure. This means that as chatter drives the damper piston rapidly back and fork in its oil-filled cylinder, the suction or refill part of its cycle has only atmospheric pressure to drive fluid through the damper valves to refill the cylinder at each stroke. As the damper is called upon to operate at chatter frequencies, this process of valve opening and damper cylinder filling falls behind because there is too little time in which to complete it. Chatter drives the damper piston rapidly back and forth but the damper oil is unable to refill the cylinder completely. The result is a partial vacuum, and a vacuum is not a damping medium.

Even if the damper cylinder does refill at each stroke, it takes time for damping valves to open and close. If this “valve transient time” is comparable to the cycle time of tire chatter, the valves will use all the time available in fluttering somewhere between open and closed, and little useful damping will occur.

In either case, the damper cannot act fast enough to keep up with the chatter frequency. Okay, we increase the lift of the damper valves to get more flow.

This makes it take longer for them to open and close, making chatter worse. Hmmm. Now we reduce the valve lift to make the valve transient shorter, but this limits the flow, pushing us toward the “pumping vacuum” syndrome.

Years of creative work have gone into finding workable design compromises for fork dampers. The parts are now beautifully made and their oil passages look as if designed by flow specialists rather than (as formerly) by plumbers. This would be adequate if motorcycle and tire design stood still. It does not. Chassis and even tire stiffnesses continue to rise, pushing the chatter frequency up as well-to numbers like 25 cycles per second. Conventional atmospheric fork dampers are fading out at this speed, putting pressure on tiremakers to build the necessary damping into their tires. They are understandably reluctant to do this, as damping converts mechanical motion into heat, the archenemy of tire life.

The above are probable reasons why the latest Öhlins racing fork has received such good pre-season reviews. Visible on the front of each fork leg is a small pressure accumulator that maintains about 10 times atmospheric pressure on the damper assemblies. This higher pressure enables smaller, lower-lift refill valves to flow adequately even at the higher chatter frequencies. The result-when all is wellis enough damping at chatter frequency to bleed energy from the chatter cycle and kill the chatter. This allows the bike to hold line normally as the rider throttles up to accelerate out of comers.

Pressurized fork dampers are a hot trend in racing. How long before they hit your local Racer Road?

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontA Gonzo Goodbye

May 2005 By David Edwards -

Leanings

LeaningsThe Leftover King

May 2005 By Peter Egan -

Departments

DepartmentsHotshots

May 2005 -

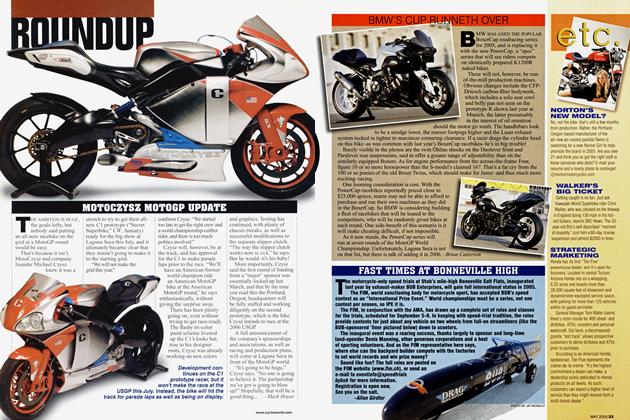

Roundup

RoundupMotoczysz Motogp Update

May 2005 By Mark Hoyer -

Roundup

RoundupBmw's Cup Runneth Over

May 2005 By Brian Catterson -

Roundup

RoundupFast Times At Bonneville High

May 2005 By Allan Girdler