THE KNOT OF FRICTION

IGNITION

TDC

PISTON GENEALOGY

KEVIN CAMERON

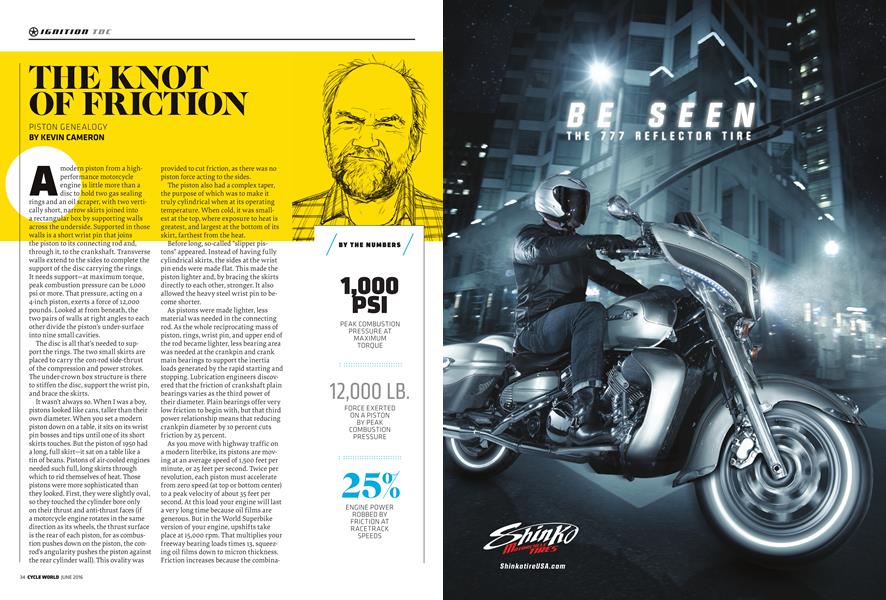

A modern piston from a high-performance motorcycle engine is little more than a disc to hold two gas sealing rings and an oil scraper, with two vertically short, narrow skirts joined into a rectangular box by supporting walls across the underside. Supported in those walls is a short wrist pin that joins the piston to its connecting rod and, through it, to the crankshaft. Transverse walls extend to the sides to complete the support of the disc carrying the rings.

It needs support—at maximum torque, peak combustion pressure can be 1,000 psi or more. That pressure, acting on a 4-inch piston, exerts a force of 12,000 pounds. Looked at from beneath, the two pairs of walls at right angles to each other divide the piston’s under-surface into nine small cavities.

The disc is all that’s needed to support the rings. The two small skirts are placed to carry the con-rod side-thrust of the compression and power strokes. The under-crown box structure is there to stiffen the disc, support the wrist pin, and brace the skirts.

It wasn’t always so. When I was a boy, pistons looked like cans, taller than their own diameter. When you set a modern piston down on a table, it sits on its wrist pin bosses and tips until one of its short skirts touches. But the piston of 1950 had a long, full skirt—it sat on a table like a tin of beans. Pistons of air-cooled engines needed such full, long skirts through which to rid themselves of heat. Those pistons were more sophisticated than they looked. First, they were slightly oval, so they touched the cylinder bore only on their thrust and anti-thrust faces (if a motorcycle engine rotates in the same direction as its wheels, the thrust surface is the rear of each piston, for as combustion pushes down on the piston, the conrod’s angularity pushes the piston against the rear cylinder wall). This ovality was provided to cut friction, as there was no piston force acting to the sides.

The piston also had a complex taper, the purpose of which was to make it truly cylindrical when at its operating temperature. When cold, it was smallest at the top, where exposure to heat is greatest, and largest at the bottom of its skirt, farthest from the heat.

Before long, so-called “slipper pistons” appeared. Instead of having fully cylindrical skirts, the sides at the wrist pin ends were made flat. This made the piston lighter and, by bracing the skirts directly to each other, stronger. It also allowed the heavy steel wrist pin to become shorter.

As pistons were made lighter, less material was needed in the connecting rod. As the whole reciprocating mass of piston, rings, wrist pin, and upper end of the rod became lighter, less bearing area was needed at the crankpin and crank main bearings to support the inertia loads generated by the rapid starting and stopping. Lubrication engineers discovered that the friction of crankshaft plain bearings varies as the third power of their diameter. Plain bearings offer very low friction to begin with, but that third power relationship means that reducing crankpin diameter by 10 percent cuts friction by 25 percent.

As you move with highway traffic on a modern literbike, its pistons are moving at an average speed of 1,500 feet per minute, or 25 feet per second. Twice per revolution, each piston must accelerate from zero speed (at top or bottom center) to a peak velocity of about 35 feet per second. At this load your engine will last a very long time because oil films are generous. But in the World Superbike version of your engine, upshifts take place at 15,000 rpm. That multiplies your freeway bearing loads times 13, squeezing oil films down to micron thickness. Friction increases because the combination of higher sliding speed and thinner oil films dramatically increases the rate of oil shear in bearings. On the freeway, friction may be taking to to 15 percent of engine power, but on the track that rises to more like 25 percent. Taxation without representation!

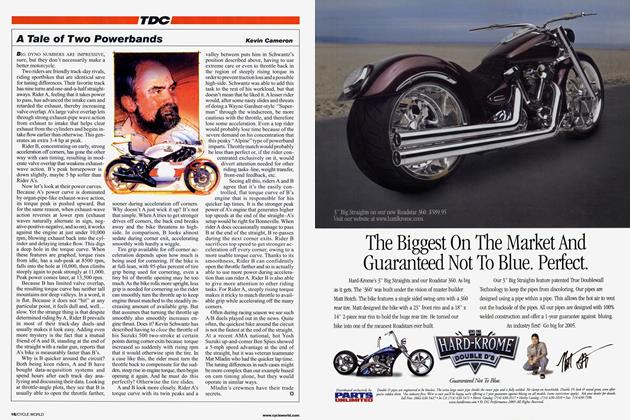

BY THE NUMBERS

1,000 PSI PEAK COMBUSTION PRESSURE AT MAXIMUM TORQUE

12,000 LB. FORCE EXERTED ON A PISTON BY PEAK COMBUSTION PRESSURE

25% ENGINE POWER ROBBED BY FRICTION AT RACETRACK SPEEDS

To combat this rising loss, engineers have taken every possible bit of mass out of pistons, wrist pins, and con-rods. Instead of making piston crowns thick enough (heavy!) to conduct combustion heat out to the cooler cylinder wall (which now has liquid coolant behind it), oil jets are aimed up at the undersides of piston crowns to take over this cooling function. With oil jet cooling, piston crowns are made thinner. This is a cascade of benefits, allowing crankpin and main bearing diameters to be reduced, and crank counterweights to be made less massive. Oil viscosity has also been reduced and bearing clearances closed up to suit.

Looking at super-short modern pistons, a first thought is, “Why, there’s hardly enough skirt there to keep these things square in the bore!” There’s some truth to that because barrel-faced top rings are a common choice; their slightly curved wear face is more tolerant of misalignment than are conventional square-faced rings. The curved ring face also does a better job of “surfing” on the thin oil film left on the bore by the oil scraper ring.

Piston rings seal at speed because combustion gas gets behind them, pushing them out against the cylinder wall. The wider the ring, the greater the area of this pressure, and the greater ring friction becomes. Therefore over the years piston rings have been made thinner. Pistons of racing engines have only two rings: one gas sealing ring and an oil scraper. Because scraper rings exert high wall pressure, oil control has a cost in friction, so race engines often employ “relaxed pressure” oil scrapers together with a crankcase vacuum pump to help with oil control.

Another area of concern is how quickly combustion gas can get behind the top ring as combustion begins. If the ring’s up-and-down (axial) clearance is too great, it lets combustion gas inflate the ring prematurely (all that’s required is enough pressure to keep the ring against the bottom of its groove), generating excessive ring friction. The piston manufacturer adjusts ring axial clearance to find a sweet spot—the lowest friction combined with keeping the ring where it belongs.

Even lighter pistons could be made of new dispersion-hardened aluminum alloys. That would start another cascade of friction reductions. There are no ultimates.

“IN THE WORLD SUPERBIKE VERSION OF YOUR ENGINE, UPSHIFTS TAKE PLACE AT 15,000 RPM. THAT MULTIPLIES YOUR FREEWAY BEARING LOADS TIMES 13, SQUEEZING OIL DOWN TO MICRON THICKNESS."

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMan, Van, Plan

June 2016 By Mark Hoyer -

Intake

IntakeIntake

June 2016 -

Ignition

IgnitionConverted And It Feels So Good

June 2016 By Bradley Adams -

Ignition

IgnitionPre-Ride Techniques the Toys of Summer

June 2016 By John L. Stein -

Ignition

IgnitionFrogger With Blood

June 2016 By Peter Jones -

Klr650 Adventure Time

Klr650 Adventure TimeKiller Tacos

June 2016 By Bradley Adams