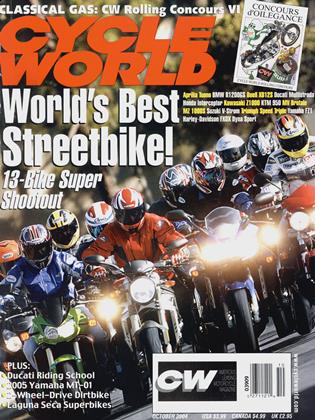

SERVICE

Paul Dean

Where the rubber doesn't meet the road

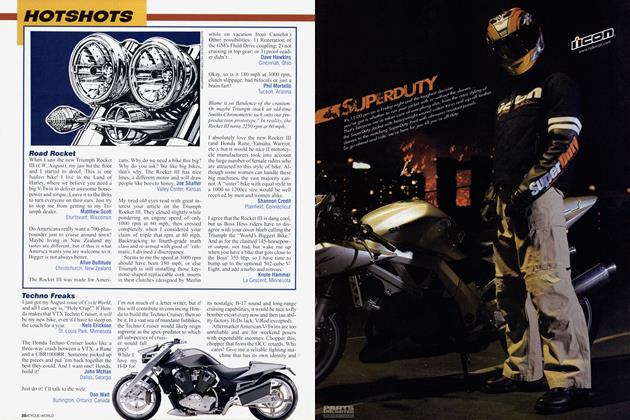

I enjoyed Kevin Cameron's July-issue "Rubber Revolution" article that described how tires are manufactured, even though he lost me a few times with all the technical jargon. But I have questions about the service life of the current crop of motorcycle tires. Why do we still only get 8000-10,000 miles on a rear tire? I ride a Honda Valkyrie and, like many of my fellow Valkyrie riders, have switched to a 205/55-16 car tire on the rear. I put up to 15,000 miles a year on my bike and have noticed little or no difference in handling between my Yokohama car tire and the Metzeler I was using, except that I now get three to four times the mileage. When will motorcycle tire manufacturers build a tire that will get more mileage? Rick Mullins Arlington, Texas

If achieving such a goal means that the rubber companies have to build motorcycle tires shaped like car tires, I hope they never succeed. I 've ridden several bikes that were shod with car tires in the rear, and if I never have to ride one again, it will be much too soon.

Because of the extreme differences in

the way the two types of vehicles corner (slip angles with a car, camber thrust on a bike), a car tire has an entirely different type of construction than a motorcycle tire. The most obvious-and maybe the most important-is that one has a perfectly flat tread surface while the other has a distinctly curved surface. The bike tire is curved because in order to turn, the entire motorcycle must lean; the curvature of the tread allows the all-important contact patch between tire and road to be relatively consistent in size and shape, no matter if the bike is perfectly vertical or leaned over at an angle. An automobile tire is flat because a car ’s suspension works to keep the entire tread surface in contact with the road while the rest of the vehicle leans slightly in corners.

When you put a car tire on a motorcycle, you not only change the bike’s handling characteristics, you significantly reduce its handling capabilities. As a bike leans over on a car tire, the size of the contact patch is drastically reduced, simply because most of the tire ’s flat tread surface is no longer in contact with the ground; instead, the

tire has to ride up on the very edge of its shoulder, meaning that the contact patch is only a skinny little strip of rubber that was never intended to give a banked-over motorcycle good stability\ And because the wide tread surface is flat rather than radiused, banking over into a turn requires the rear of the bike to be lifted upward onto the tire ’s edge, thereby greatly increasing the effort that has to be exerted on the handlebar.

Also consider this: Add up the total contact-patch area of a typical car, taking into account that it has four wheels shod with wide tires, each of which offers a full-width contact patch. Then compare that with a motorcycle, which has only two wheels shod with curved tires, each of which offers a contact patch that is only a fraction of the tire ’s width. Obviously, the bike tire provides far less area; in many instances, the contact patch of just one car tire is much greater in area than the total patch area of both motorcycle tires. Bike tires also tend to be stickier (read: softer), because while a bit of incidental tire slippage on four wheels usually produces little more than an "Oops! ” on the part of the driver, on two wheels it can result in a serious crash.

Contrary> to what you might think, motorcycle tire manufacturers are constantly working to produce highermileage tires, but they aren 't willing to sacrifice a lot of grip to do so. And I, for one, am pleased with that philosophy. Everything that a motorcycle does is, in effect, an interaction with the road, but it only touches that road in two very small patches; I don't know about you, but I want those patches to be the stickiest, most efficient ones reasonably possible, even if it means replacing the tires at frequent intervals.

You claim to have felt no significant handling differences between a Metzeler bike tire and a Yokohama car tire. Well, Rick, I sincerely hope you never do. Especially if you ever have to make a sudden, severe turning maneuver to avoid something directly in your path.

Crazy 8s or sweet 16s

You were spot-on in your assessment of the great expense of valve adjustments on a VTEC Honda VFR ("The price of technology," Service, August). But I was surprised to learn that a tuneup on a Hon da VTEC car does not cost as much as it does on the bike because the implemen tation of the car's system was done dif

ferently. According to Honda, it has something to do with available space.

A friend of mine has a VTEC VFR and also has been somewhat disappointed with its lower-rpm performance, as well as the sudden shift in acceleration that occurs when transitioning from twoto four-valve operation. He was looking at installing a

Power Commander but found that they do less on a VTEC than they do on other bikes. My question is, can the eight VTEC valves be un-VTEC’ed and converted to full-time operation? Theoretically, this would reduce tuneup costs and unlock power. The idea that a VTEC VFR built in the past meets a standard designated for the future provides my friend with less incen tive to keep his VFR than would better per formance. Thank you for any attention you might give this question. Ken Applegate Puteaux, France

I `m not cure how easily a VTEC VFR could be switched to full-time 16-valve operation. I don `t know of anyone who has ever performed that conversion, and no one I contacted at American Honda had a clue about such a modification. Mv educated guess is that it %t'ouldn `t be as easy, as cheap or as e/fective as iou might think. Labor charges would at least in volve the removal of both cylinder heads so that all eight VTEC valve guides could be replaced with their conventional coun terparts, along %t'ith all eight VTEC tap pets and 16 valve springs (inner and out er). Add in the standard-sir/c retainers, collets and shims for those eight valves', and the parts costs begin to mount. The VTEC and VFR cams and valves are the same, howeve,: so they could be retained. The injection mapping is not configured fOr optimum fuel deliveri at sub7000 rpm with all eight valves working, al though that could probably he remedied `~t'ith a Power Commander But the intro duction of twice the intake-valve area at

lower revs is likely to slow intake flow in that rpm range, which would tend to hamper bottom-end performance rather than enhance it.

Without any reputable engineering input or actual experience to draw upon, you would be conducting what amounts to an R&D experiment. Bi the lime you were finished, you could end tip realizing no in crease in overall perJhrmance while spending more than you would have on a couple of complete valve-adjustment pro cedures.

Like, totally gross

Could you please explain what "GVWR" stands for? I want to know for the enlight enment of the local Harley riders who read

your March-issue road test of the Road King Custom. They saw the different weight specs in that test and concluded that "dry weight" means that the bike's "chas sis" weighs 709 pounds, and that GVWR means the complete motorcycle (fenders, gas tank, etc.) weighs 1259 pounds. I'm aware that GVWR is the loaded weight, but does it mean that if you exceed that limit, the motorcycle would be considered overloaded and out of warranty, for legal or other reasons? J.W. Salter Posted on www cycleworid. corn

GVWR stands for Gross Vehicle Weight Rating, which is the maximum weight the motorcycle and its cargo should attain as recommended by the bike 's manufacturer. Dry weight is the weight of the entire motorcycle without fuel in the gas tank, but topped up with all other necessary fiuids-engine oil, fork oil, battery electrolyte, coolant (if applicable), etc. The difference between the dry weight and the GVWR represents the maximum payload the manufacturer believes the motorcycle should carry\ including rider, passenger, luggage and, of course, fuel.

Each bike 's GVWR is calculated by applying a number of different criteria. Some people mistakenly think that GVWR is dictated simply by the combined load ratings of the bike s tires, but that ’s not so. If you total the recommended maximum weight ratings listed on the sidewalls of a motorcycle 's two tires, you end up with a figure that exceeds that bike's GVWR, usually by a large margin. The manufacturers take those tire ratings into consideration, but they use some reasonably complex parameters to determine GVWR. And for the most part, those ratings are established more for reasons of safety than for any concerns about the bike's structural limitations.

One of the more important factors in this process is not just the sheer amount of weight that a bike might be able to carry, but also where it wvuld carry that weight. The engineers consider factors such as the height of the bulk of the payload, as well as its location in relation to the axles. All this has significant effect on the bike s fully loaded center of gravity, which can have major impact on its handling and stability, w hether turning, braking or accelerating.

So, if you exceed the GVWR-at least within reason-the tires won 't blow out and the frame won't collapse. But if you exceed the tires ' weight ratings, you 're asking for trouble. And if you overload the bike and then ride it for long periods at very> high speeds, tire failure becomes more possible. The enemy of tires is w eight and speed; if you embrace both those adversaries to excess, all bets are off.

Does exceeding the GVWR void the warranty? There is no concrete answer to that question. First of all, a dealer or a manufacturer usually has a tough time proving-or even knowing-///^/ a bike had been overloaded. If one of their representatives witnessed or photographed such an act-or if the combined weight of the known rider and passenger clearly exceeds the maximum payload-they may choose to void the warranty, but even that depends on the nature of the failure. A broken valve spring or failed oil pump could not legitimately he blamed on ex cessive payload, sin ` neither component is afjècted b~' the overall iieight of the motorc~'cle. But failures such as a broken fra,ne or a blown-out shock could be the direct result of o `erweighting and i mild likely prompt the dealer or manufacturer to reject a warranti claim.

Got a mechanical or technical problem with your beloved ride? Can't seem to find work able solutions in your area? Or are you eager to learn about a certain aspect of motorcycle design and technology? Maybe we can help. If you think we can, either: 1) Mail a written inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/6310651; 3) e-mail it to CWlOean@aol.com; or 4) log onto www.cycleworld.com, click on the "Letters to the Editor" button and enter your question. Don't write a 10-page essay, but if you're looking for help in solv ing a problem, do include enough informa tion to permit a reasonable diagnosis. And please understand that due to the enormous volume of inquiries we receive, we cannot guarantee a reply to every question.

View Full Issue

View Full Issue