A Short History of Chassis Flex

TDC

Kevin Cameron

MOTORCYCLE CHASSIS HAVE ALWAYS flexed. The earliest motor-bicycles flexed so much that they broke their frames, so bigger and heavier-walled tubing was tried until durability improved. We’ve been experimenting ever since.

At various times, inventors hit upon the idea of building motorcycle chassis as bridges were built-as stiff, triangulated structures whose properties could be calculated. It failed to catch on, probably because the resulting stiff ride was so rough that no one could stand it. On the other hand it was clear that tail-wagging, occurring as chain-pull hauled the rear wheel to one side, was very upsetting because it destroyed stability. To counter this, “stays” were added-extra longitudinal members joining the rear axle to the gearbox. This made it clear that stiffness had its uses.

In the 1920s and ’30s, the girder fork was supreme-a pair of uprights made from small-diameter tubing, bolted to the front axle below and moving up and down on four forward-facing swing-links joined to the steering head above. Such forks were stiff enough fore and aft but flexed laterally so much, especially in sidecar use, that the front tire might rub the insides of the girders during hard cornering. Sometimes lateral stays were added to the girders, and sometimes riders just put up with the uncertainty.

Vincent guru Sid Biberman relates that Douglas built dirt-track racers, and one day in the 1930s a certain newly finished bike was found to hook up on the company’s test track exceptionally well. What could be the cause? Measurements were taken but nothing was found amiss-until one practical person pointed out that the engine bolts had never been tightened! When they were, the mysterious handling excellence disappeared. This and doubtless many other such accidental experiences created a hazy idea that somehow, making a chassis too stiff might not be a good thing. It wasn’t science, but it wasn’t wrong, either.

Just before and after WWII it was clear that some kind of suspension at both ends would take over from the girder/hardtail frame concept. Bikes were now too fast to stay hooked up while their tires bounced and hammered over rough pavement. Rex McCandless gathered up the best of the possibilities into the chassis he built for Norton’s 1950 TT effort. This chassis-later named “Featherbed” for its smooth ride-employed hydraulic damping at both ends with a swingarm rear suspension and telescopic front. The soft, bump-eating qualities of this classic design would obscure the chassis flex issue for a long time. Suspension flex was king!

Specialist frame-builders in England retained the idea that chassis flex is hard to avoid, and that it’s usually better to let at least some occur than try to brace a chassis so much that it fails instead. Yamaha’s illustrious TZ750 roadracer underscored this point by always cracking its frame tubes in the same places. If it didn’t, your rider wasn’t riding hard enough! Meanwhile, the slicktire revolution took place and grip shot up, obsoleting flabby pipe frames by making them wobble. Stiffness to the rescue! During the 1980s, chassis stiffness increased rapidly, first in Grand Prix racing where it seemed to be the key to stability, and then on streetbikes. Occasionally, disturbing things happened to confuse the issue. When one of Yamaha’s 250cc GP bikes refused to hook up at an early ’90s event, a crewman who remembered the murmured truths of the past took a hacksaw to the frame. On that particular track, the result was good. Elsewhere? Not so good.

Through the 1990s, talk about chassis flex was limited to whispers, and when highly paid handling consultants in desperation sawed through swingarm bracing or deleted a cross-tube here and there, no papers were published in learned journals. Destroying the stiffness all had worked so hard to create seemed somehow shameful, a sacrilege.

In the late ’90s, Honda took up the cause with its customary enthusiasm, producing some testand racebikes that seemed like Jell-O to riders raised on rigidity. Team managers spoke cautiously to journalists about a search for “good chassis flex,” as opposed to “bad” flex.

Was a hooked-up chassis to remain a happy accident forever? Would there never be an underlying theory that could tie all wishes and suspicions together? As recently as 2002, major companies seem to have been still at the level of the 1930s Douglas dirt-tracker-finding accidental value in loose or deliberately missing engine bolts. But the secret work was gaining respectability as it discovered more things that worked, and even some inkling of why. Single-sided swingarms have a killer high-tech look that’s hard to reject, but when they flexed they also did some unpredictable steering of their own. Upsetting! And so old, uncool-looking twin-beam swingarms were brought back. When these flexed sideways, their symmetrical beams acted like parallelogram links to keep the rear wheel on a constant heading. Stability! Now it was possible to think about increasing their twist resistance by making the beams deeper vertically, while controlling their lateral “spring constant” by varying beam lateral thickness.

As you can see elsewhere in this issue, I think we are now moving into an era in which the front of the main frame will provide the same lateral compliance for the front wheel. This is more complex because the large leverage of the long fork tubes greatly complicates the avoidance of twist. This may be an ideal problem to be investigated by Finite Element Analysis, now a well-developed technique with an established cadre of “FEA jocks.”

Computer, please generate for me a family of N structures which provide X lateral compliance, while keeping steering-head twist within Y tolerance. And now I hit Return, and begin to think vaguely of where to go for lunch. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontSecret Daytona

JUNE 2004 2004 By David Edwards -

Leanings

LeaningsWhat To Do In Winter

JUNE 2004 2004 By Peter Egan -

Departments

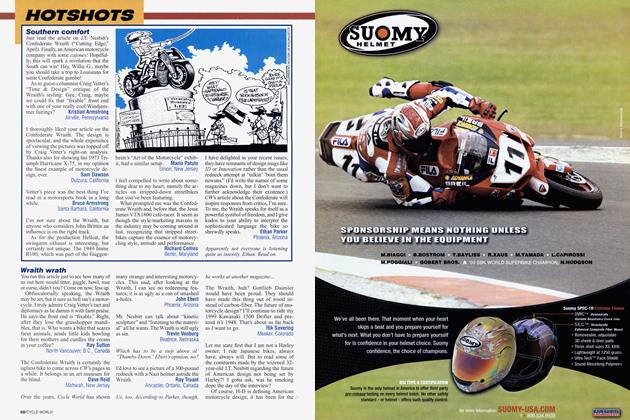

DepartmentsHotshots

JUNE 2004 2004 -

Roundup

RoundupMonster Max!!!

JUNE 2004 2004 By Steve Anderson -

Roundup

RoundupFormula Bmw: K-Bike Power For F-1 Hopefuls

JUNE 2004 2004 By Kim Wolfkill -

Roundup

RoundupEtc

JUNE 2004 2004