Imitation of life

TDC

Kevin Cameron

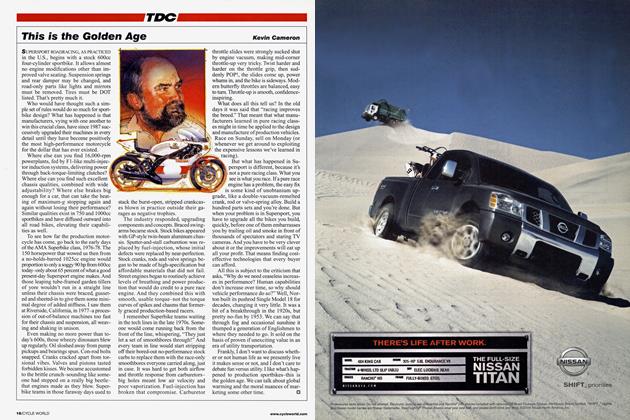

IN THE EARLIEST DAYS OF MOTORING, gasoline was not “made” in the sense that modern fuels are, but was simply a volatile fraction of crude oil, separated from it by simple distillation. They heated up a batch of crude until a range of molecular weights boiled off, then collected it in a condenser.

Demand for gasoline grew large enough to exceed what could be had in this way, but simply distilling more crude built up surpluses of unmarketable by-products. Therefore ways of breaking down these by-products into more gasoline were sought. The first technology was to heat the residue in sealed chambers, to temperatures high enough that the big molecules were broken-“cracked”—into gasoline-like fragments.

To avoid the high energy cost of this thermal-cracking process, catalysts were introduced. A catalyst is a substance that accelerates the rate of a chemical change, without itself being consumed in the process. Heavy metals like platinum maintain strong electric fields near them. A fuel molecule adsorbed onto such metallic surfaces is deformed, making it easier for chemical bonds to be broken or altered. This catalytic (“cat”) cracking greatly increased the yield of gasoline from crude. Later it was found that by passing the petroleum feedstock through successive reactors, employing different catalyst systems in each, the process of reshaping fuel molecules could be, to a large degree, steered to produce more of a desired product, and less of undesired products.

A further refinement allows only certain sizes and shapes of molecules to reach sites with catalytic activity. Special “molecular sieves,” called zeolites, are provided with catalytic sites inside their pores, so particular molecules can reach the catalyst and others cannot. All the current talk about “reformulated gasolines” as a pollution-abatement scheme hinges upon this technology of reshaping fuel molecules almost at will; to start with petroleum’s great variety of molecular types, then transform it into whatever particular types are required for any purpose.

This molecular shaping is beginning to mimic what living systems do automatically and with great and elegant specificity. Sugars, fatty acids and car-

bohydrates arrive in our cells as our “petroleum.” In a gross sense, it is the combination of these fuels with oxygen that generates the energy that keeps us alive. But this “burning” of fuel is not the rapid, heat-producing variety found in an engine’s cylinder. Instead, the fuel molecules pass through a chain of catalytic processes, reminiscent of a super-sophisticated oil refinery.

The catalysts of life are called enzymes, and are proteins of complex shape which fit and act upon only specific molecules. When such a molecule adsorbs onto the corresponding enzyme, changes like those found in cat cracking or reforming take place; bits of the molecule are snipped off, added or rearranged. The altered molecule then desorbs from the enzyme. Because the “machinery” of a living cell cannot work at higher temperatures, it must be protected from any rapid release of heat of the kind that propels internal combustion engines. Therefore the energy is released in many small steps of manageable size, as the original fuel molecule rattles down through a chain of many enzymatic changes. The energy released in these small steps is used to make the standard internal fuel of life, ATP. This is our “reformulated fuel.”

The incredible part of all this is that this complex, many-stepped process is highly efficient; generally something like 40 percent of the original energy later appears as ATP. The part of the cell where this goes on is the mito-

chondrion, on whose inner membrane the enzymes are located. An average human body has something like 10 acres of this wonderful, fuel-transforming membrane. This, in turn, is reminiscent of a recent man-made energy-transforming device, the fuel cell, which converts chemical energy directly into electricity. At present, fuel cells require simplified fuels (hydrogen, methane, alcohol, etc.) to operate for any length of time, but the efficiency of the best technology is very high-on the order of 50 percent. Fuel-cell technology is beginning to sound more biological than industrial.

It should be no surprise that, as petroleum chemistry becomes more sophisticated, and our understanding of biological processes widens, biology increasingly provides models for industry. It’s not unreasonable, therefore, to look forward to a future in which enzymatic reactors-really large, man-made mitochondria-will alter complex petroleumor coal-derived fuels that present-day fuel cells cannot handle, delivering as output some standard, manageable molecule to the vehicular fuel cells that finally generate electricity.

Are you among those who just say no to electric vehicles? We now associate electrics with sluggish, no-fun performance, but that’s not the fault of electric motors or of electricity. It is present-day battery power that is weak; high-performance electric motors can deliver all the acceleration anyone wants, provided they get plenty of juice and don’t have to tote a ton of batteries to get it. The neat thing about electricity is that it is so controllable and can be used in so many ways-without needing masses of shafts, gears, cams and linkages. A fuel-cell cycle, based upon available petroleum fuels that have been structurally simplified by a “bio-reactor,” is a fascinating possible future transportation power source.

Have no fear; flaming combustion power, applied via the exciting, vibrating, roaring piston engine, will still rule the roost for a while. But change is in the wind, and we may in time come up with useful, versatile and efficient alternatives to just setting fuels on fire and burning them for their heat. Greater sophistication awaits.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontUps And Downs 1993

January 1994 By David Edwards -

Leanings

LeaningsGeneral Declutteration

January 1994 By Peter Egan -

Letters

LettersLetters

January 1994 -

Roundup

RoundupHonda Fills A Gap

January 1994 By Jon F. Thompson -

Roundup

RoundupWill This Be the New Cbr600?

January 1994 By Jon F. Thompson -

Roundup

RoundupHusqvarna Happy

January 1994 By Alan Cathcart