All in a row

TDC

Kevin Cameron

THE VERTICALLY SPLIT, TWO-PIECE crankcases of early single-cylinder motorcycle engines were like pairs of thick-walled pie-pans enclosing the crankshaft. This meant that after casting, they could be machined in an ordinary lathe to accurately center the two main-bearing bores. Simple.

Knowing in the 1930s that motorcyclists wanted more power than one cylinder could manage, Edward Turner designed his 1937 Triumph Speed Twin so its nearly spherical crankcase could still be made in the old two-piece, vertically split way. This required nothing new in the way of production tooling. The British motorcycle industry’s main product remained two-bearing vertical-Twins of this type until its end in the late 1970s.

Long ago, no one wanted to tackle í the problem of putting more than two main bearings in a row because it wasn’t easy to arrange them all on the same centerline with common machine-shop equipment. A tedious way around this was to fit plain main bearings by “scraping.” Soft-metal plain bearings were poured (cast) into crankcases, with a round bar taking the place of the crankshaft. Then the bearings were hand-scraped into uniform contact with the crank by a time-honored process. The crank main journals would be thinly coated with the vivid pigment Prussian Blue, and the crank would be lowered into the bearings. Wherever the journals touched the bearings, blue pigment would be left behind. By manual scraping of these areas through many repetitions, an experienced craftsman could achieve a fair fit of crank to bearings-making it unnecessary to finishmachine them with high accuracy. The drawback was that this process was too slow for mass production.

When in the late 1940s AJS-Matchless designed its Triumph-like verticalTwin, the idea of two crankpins unsupported by a bearing between drove engineers to provide a third, center main bearing. This took the form of a split plain bearing made as part of a diaphragm, which was then bolted between the two case halves. In service, this was usually the first bearing to fail, leading to the remarkable belief that a center bearing was actively harmful! In fact, the likely cause was poor centering. In the racing G45 500cc Twin, a special procedure existed for more ac-

curately centering that bearing.

In the larger world, two-row radial aircraft engine crankcases were being routinely assembled from three pieces, all machined so that three main bearings came out accurately on the same centerline. In California, four-cylinder autoracing engines were built by assembling AJS-like main bearing diaphragms onto the five-crank mains, then sliding the crank with diaphragms into the barrellike crankcase endwise. This construction depended upon expert manual setup.

England’s pioneer machine-tool industry lost its world preeminence to Germany and the U.S. after 1875. This was the ultimate reason why Singles and parallel-Twins so long dominated English design-they were the best they could manage on simple tooling. Even AJS-Matchless soon gave up the threebearing G45 racer in favor of a sohc Single, the famous G50. Although several English manufacturers prototyped fourcylinder racing engines in the ’40s and ’50s, all agreed that such engines were impractical for production.

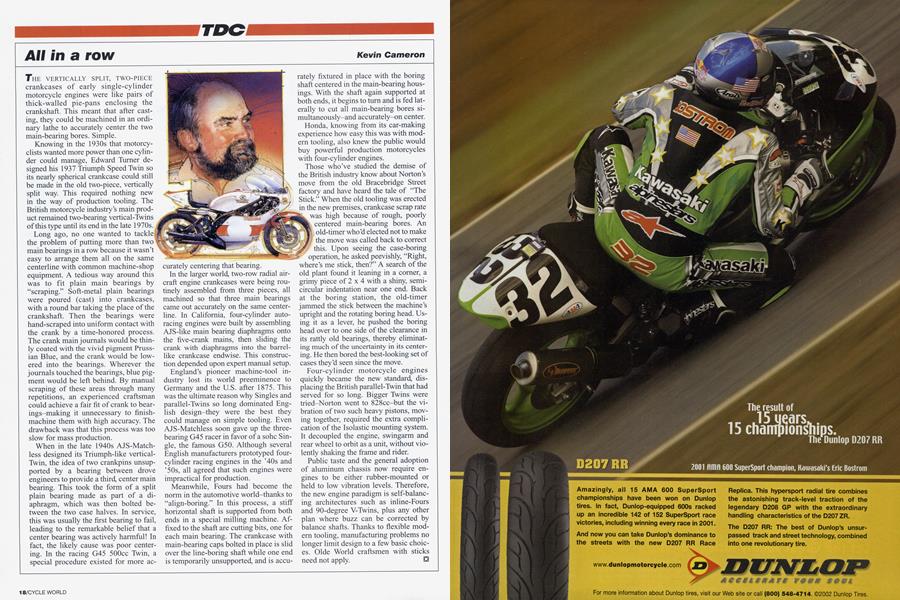

Meanwhile, Fours had become the norm in the automotive world-thanks to “align-boring.” In this process, a stiff horizontal shaft is supported from both ends in a special milling machine. Affixed to the shaft are cutting bits, one for each main bearing. The crankcase with main-bearing caps bolted in place is slid over the line-boring shaft while one end is temporarily unsupported, and is accu-

rately fixtured in place boring shaft centered in the main-bearing housings. With the shaft again supported at both ends, it begins to turn and is fed laterally to cut all main-bearing bores simultaneously-and accurately-on center.

Honda, knowing from its car-making experience how easy this was with modern tooling, also knew the public would buy powerful production motorcycles with four-cylinder engines.

Those who’ve studied the demise of the British industry know about Norton’s move from the old Bracebridge Street factory and have heard the tale of “The Stick.” When the old tooling was erected in the new premises, crankcase scrap rate was high because of rough, poorly £ centered main-bearing bores. An old-timer who’d elected not to make the move was called back to correct this. Upon seeing the case-boring operation, he asked peevishly, “Right, where’s me stick, then?” A search of the old plant found it leaning in a comer, a grimy piece of 2 x 4 with a shiny, semicircular indentation near one end. Back at the boring station, the old-timer jammed the stick between the machine’s upright and the rotating boring head. Using it as a lever, he pushed the boring head over to one side of the clearance in its rattly old bearings, thereby eliminating much of the uncertainty in its centering. He then bored the best-looking set of cases they’d seen since the move.

Four-cylinder motorcycle engines quickly became the new standard, displacing the British parallel-Twin that had served for so long. Bigger Twins were tried—Norton went to 828cc-but the vibration of two such heavy pistons, moving together, required the extra complication of the Isolastic mounting system. It decoupled the engine, swingarm and rear wheel to orbit as a unit, without violently shaking the frame and rider.

Public taste and the general adoption of aluminum chassis now require engines to be either rubber-mounted or held to low vibration levels. Therefore, the new engine paradigm is self-balancing architectures such as inline-Fours and 90-degree V-Twins, plus any other plan where buzz can be corrected by balance shafts. Thanks to flexible modern tooling, manufacturing problems no longer limit design to a few basic choices. Olde World craftsmen with sticks need not apply.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontDaytona, Dimming

June 2002 By David Edwards -

Leanings

LeaningsA Steam-Shovel And A Piece of Earth

June 2002 By Peter Egan -

Departments

DepartmentsHotshots

June 2002 -

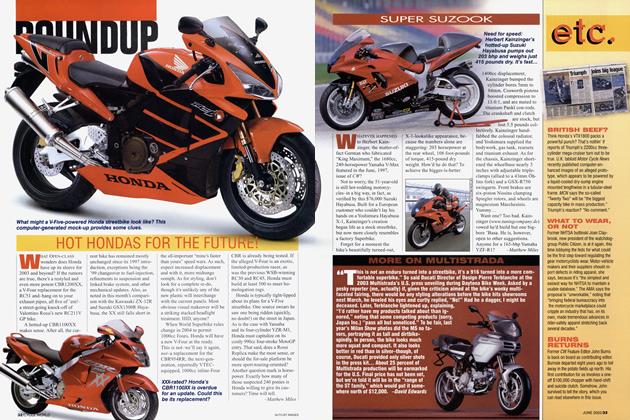

Roundup

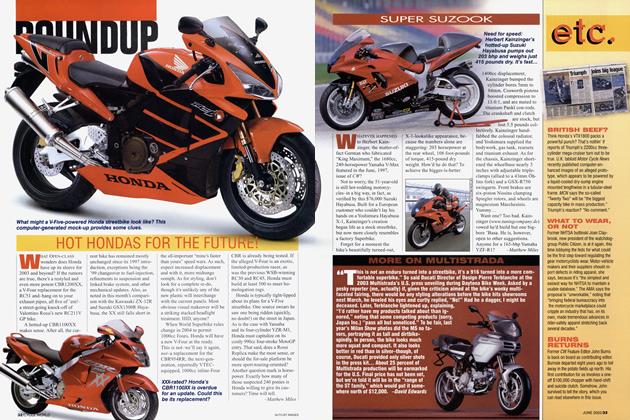

RoundupHot Hondas For the Future!

June 2002 By Matthew Miles -

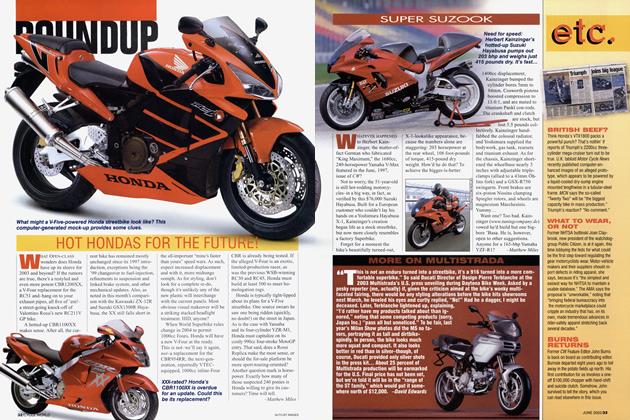

Roundup

RoundupSuper Suzook

June 2002 By Matthew Miles -

Roundup

RoundupMore On Multistrada

June 2002 By David Edwards