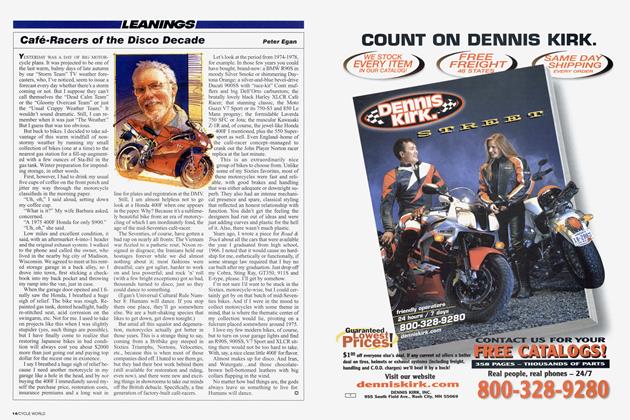

Techtips

SERVICE

When rebuilding or reassembling an engine’s top end, you need to prevent the connecting rods from flopping around any time you have to rotate the crankshaft. Here’s an easy, fail-safe method requiring just two everyday rubber bands per rod. Position each rod at about its halfway point in the stroke, then slip two rubber bands through its small-end bore and connect each one to opposing cylinder studs, forming an “X” pattern. The rubber bands will then keep each rod floating in the approximate center of the stud pattern and out of harm’s way while still allowing it to move up and down no matter how or in which direction the crankshaft is rotated. This technique works best when both rubber bands are of equal length and strength, and when they are stretched just tautly enough to support the rods. In some instances, this trick is just as effective when the pistons are on the rods, especially if you have first slipped a short section of rubber or neoprene tubing over the studs to protect the pistons and rings... just in case.

Paul dean