Y-alloy? Why not?

TDC

Kevin Cameron

PICK UP ANY MODERN MOTORCYCLE cylinder head and turn it over. In each combustion chamber you will see two or more valve-seat rings, shrunk into the aluminum head material. The rings are there because aluminum is too soft to bear the steady seating impacts of valves directly. Production seat rings are austenitic iron; those compatible with titanium valves are of beryllium-copper. The aluminum head provides maximum cooling, and the seat rings provide durability.

It wasn’t always so easy. The aluminum you could buy from a foundry in 1920 wouldn’t hold seat rings in an air-cooled cylinder head. It was too soft and expanded too much when hot. A few thousand clicks from the seating valves, combined with heat expansion, and the soft metal around the seats lost its grip, combustion gas began to leak past and all was soon lost.

World War I had shown what aluminum-a metal one-third as heavy as iron and conducting heat several times faster-could do. When peace came, everyone tried it as a cylinder head material. For British makers of air-cooled motorcycle engines, the story ended as described above. They went back to the proven material: cast iron. Foundries knew how to cast iron, valves could be durably seated against it, and it made a great cylinder surface for pistons to run upon. What could be better?

Cooling, that’s what. At first, engines of the 1920s made only modest power, and the switch from sidevalve to overhead-valve greatly reduced combustion-chamber surface area, helping engines to run cooler. Power did climb and so did the heat engines had to dissipate to cooling air. Designers corrected the early mistake of allowing the shape of overhead-valve mechanisms to block cooling airflow over the head fins. Fins were made deeper and more numerous. Tuners and engineers learned that slow combustion pushed more heat into heads and pistons. To speed combustion, many adopted four valves per cylinder, mainly for its centrally located sparkplug-which in turn shortened flame-travel time to the practical minimum. Even so, engines revving to only 5000 rpm needed long ignition timing-like 45 degrees before top center.

Torque increases with compression ratio, but so does heat. Excess heat

brings detonation, the violent, abnormal form of combustion that places an upper limit on the power of spark ignition engines. With iron cylinders, pistons and heads, combustion-chamber surfaces ran very hot because iron transmits heat slowly in comparison with aluminum. That heat brought detonation at low compression ratios like 5:1. Better, stronger aluminum did exist, but not commercially. At Britain’s National Physical Laboratory, a pioneering Australian metallurgist, Walter Rosenhain, had discovered a combination of aluminum, copper, nickel and magnesium that could be heat-treated to double the strength of pure aluminum while displaying lower heat expansion, as well. This material, called Y-alloy, could be cast or forged by 1925 to make excellent pistons-strong and requiring little running clearance. But when attempts were made to cast cylinder heads for aircooled aircraft engines from this material, it slushed and usually failed to fill the narrow fin spaces in the mold.

Meanwhile, an engineer prominent in the development of air-cooled cylinders left England and took employment at the U.S. Army’s McCook Field engine development center. This was S.D. “Sam” Heron, whose work would make possible the J-5 Wright Whirlwind engine that carried Lindbergh across the Atlantic in 1927. A metallurgist at McCook, Edgar H. Dix Jr., took up the related problem of casting cooling fins in

the English-developed Y-alloy, and in time solved it. Using Dix’s process, American aircraft engine builders were soon using cast Y-alloy heads on an expanding range of commercial and military radial engines.

Britain’s sporting single-cylinder motorcycles continued to make do with iron parts until the need for sales-boosting Isle of Man TT wins pushed power-and heat-to levels iron couldn’t handle. The next step was heads of higher heat conductivity aluminum-bronze. As heavy as iron, they cooled better, allowing compression ratio to be pushed up. Bronze, a tough material, needed no valve-seat rings. Meanwhile, British bread-and-butter bikes, many still powered by sidevalve engines, re|\ tained iron heads and cylinders.

Weight had become a problem on sporting motorcycles, making the extra 10 pounds in a bronze head a liability. In the early 1930s head cooling was therefore improved again by making only a skull, including the valve seats and sparkplug boss, out of bronze, and completing the rest of the head by pouring it in aluminum. Sometimes the castin bronze insert took the form of “spectacles” rather than a complete skull.

Years after Dix solved the problem of casting cooling fins in Y-alloy, Velocette began in 1935 to cast entire heads of this metal, which retained valve seats well. Velo practice was to heat the cylinder head to about 400 degrees F in an electric furnace, then quickly push the rings in place, using a jig to guarantee alignment. When BSA adopted all-aluminum head construction on its sporty Gold Star Single of 1937, it used established Rolls-Royce aircraft engine practice and screwed the seats in place.

Norton, on the other hand, retained the bronze-skulled aluminum head on its Manx roadracers until 1950, when it finally adopted shrunk-in valve-seat rings. Triumph’s postwar “Grand Prix” 500 Twin employed an aluminum head poured around iron skulls, as did Honda’s classic GP roadracers of the 1960s. The iron, although not ideal for cooling, provided durable valve seatings, and for Honda eased the difficult problem of head cracking between tiny paired exhaust valves. Today, all-aluminum heads with shrunk-in seat rings are the norm.

Technology can take a long time to move from its point of origin to general use!

View Full Issue

View Full Issue

More From This Issue

-

Up Front

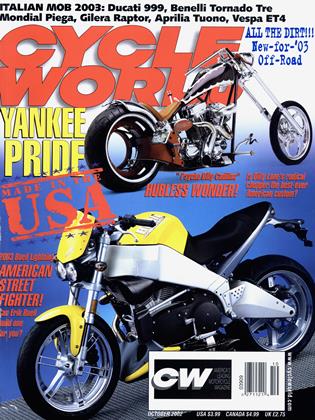

Up FrontI, Ducatista

October 2002 By David Edwards -

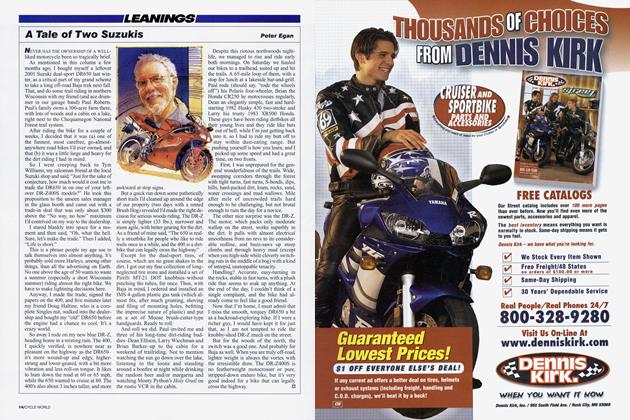

Leanings

LeaningsA Tale of Two Suzukis

October 2002 By Peter Egan -

Departments

DepartmentsHotshots

October 2002 -

Roundup

RoundupCruising In Luxury: Bmw R1200cl

October 2002 By Matthew Miles -

Roundup

RoundupCentennial Harleys

October 2002 By Matthew Miles -

Roundup

RoundupSpecial-Issue Yamahas

October 2002 By Matthew Miles