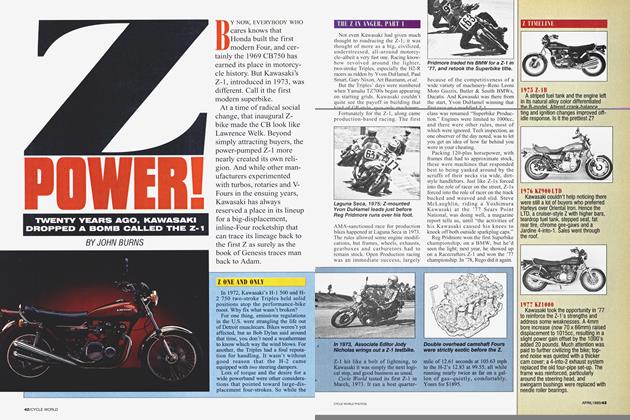

MV AGUSTA F4

Somewhere, the Count is a very happy man

KEVIN CAMERON

THE STILLNESS is SHATtered by the passing shriek of a four-cylinder engine with megaphones. As the sound accelerates away, tones and over tones warble up the scale. As the sound dies away. I hear a voice. intoning the years and the dates of countless Grands Prix won. Dark figures appear. and light picks out the objects they are pushing into view-red-and-silver racing motorcycles with long, black megaphones. Although I see some Twins and even Singles. most of the machines have four cylinders. A collage of familiar faces appears. largest among them that of Giacomo Agostini. The dream fades. If you are attentive as you drive out of Milan's Malpensa Airport. you will see a small sign pointing to Gallarate.

This is the place in which Count Domenico Agusta produced the famed MV Agusta motorcycles. This was never a self-sustaining business; although some production machines were built, the racing machines were constructed because the Count desired it. He, who held the license to produce Bell helicopters, could do as he liked, and he liked racing motorcycles.

The Count did not live forever, and neither did his racing enterprise. Because of the special place that MV Agusta holds in the memory of great deeds, however, these names, these images and faces, are perdurable.

We’re accustomed to attempts to revive that which ought not to be. A Ford chassis with a plastic body on it is not a Duesenberg. Yet now, the MV Agusta name may have found a worthy son and live again. That is the intention of the Castiglioni brothers of Cagiva, whose creation, the F4, will bear the MV Agusta name to which they own rights.

All who have any feeling for European motorcycles have enjoyed the evolution of Ducati’s ottovalvole 851, which has become the current 916. This machine has met Japanese opposition in World Superbike roadracing and come away with six world titles. Others, less impressed, have insisted this success owes more to the Ducati’s close-to-1000cc displacement than to other attributes. This has fired an ambition to tackle the Japanese designers on their own chosen ground-the four-cylinder 750. As it happens, the present near-universality of the transverse inline-Four is traceable back in time to an Italian point of origin. This fact only sharpens the ambition of Cagiva to cross swords with Japan.

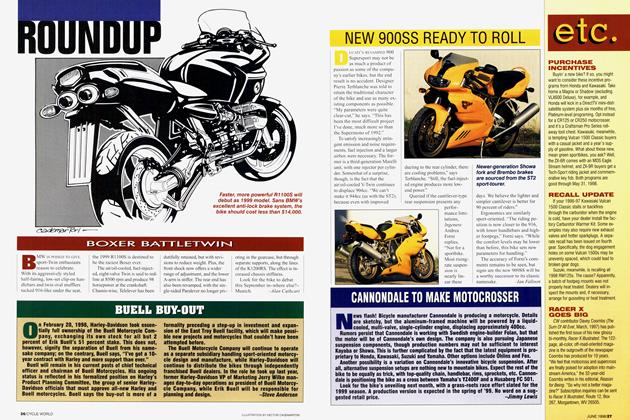

Here is the sword, the MV Agusta F4. As you can see, this is a very beautiful machine, the kind we expect from Italian stylists. There is no overt innovation here-just careful execution. This is nothing like Bimota’s Tesi, with its revolutionary forkless front end. The obvious points are completely normal: an upside-down fork with Suzuka-style quick-release axle dropouts; a single-sided cast swingarm; five-spoke light-alloy wheels with twin, 310mm floating discs at the front; Superbike-style Nissin six-piston billet calipers; carbon-fiber fenders; fine detail work everywhere. And the red-and-silver paint scheme of hallowed tradition.

This conservatism is completely correct. If this motorcycle is to be raced, as well as offered to the public, it must be able to take full advantage of existing tire and suspension technology, as well as to accommodate established rider preferences (I almost said “prejudices”). Projects that attempt a revolution at every point of design nearly always fail, and even a glorious failure is still not a success.

In particular, the specification calls out a 55.6inch wheelbase, with a claimed dry weight just under 400 pounds. At the front, a Showa fork with 49mm stanchions provides 4.5 inches of travel. This diameter is beyond anything currently in use in either Superbike or GP racing, where 46-47mm is large, and 42mm is still favored. At the rear, the stylish cast swingarm provides 4.8 inches of travel, the motion controlled through linkage by an Öhlins damper. In these details, the machine is quite conventional and indeed, all Superbikeclass machines closely resemble each other in these respects. Brakes, wheels and suspension can almost be regarded as a “Lego System” of high-quality building blocks, from which designers choose what they want-or think their customers can afford.

The chassis is of two metals. The main bridge, from steering head to the rear of the engine, is multiple round steeltube construction of the kind now termed “trellis.” At two points on the rear of the engine, this steel section is joined to a pair of aluminum uprights that carry between them the swingarm-pivot points and mountings for the suspension linkage. Unlike the Ducati 916, therefore, the swingarm does not pivot in the gearbox casting. Why not adopt Ducati’s system, now being employed by Honda on some designs? Because swingarm-pivot height has become an important chassis-tuning variable-it should not be fixed in one place.

The heart of the matter is the engine, and our curiosity focuses on how it aims to achieve something that the Japanese have not already. Outwardly, it is a 73.8 x 43.8mm inline-Four, its cylinders steeply inclined forward. It is equipped with Weber-Marelli fuel injection. This bore is a trifle larger, the stroke a bit shorter, than current Japanese numbers, but the difference is small. As racing engines are expected to operate at piston speeds in the range of 4500 feet per minute (piston speed is twice the stroke, in feet, times the rpm). This would suggest a working (racing) peak rev ceiling of 15,700 rpm, right with or ever-so-slightly above current 750 Superbikes.

Rob Muzzy says that he can run his Kawasakis a thousand revs higher than their current level, but they don’t gain power even when port and valve sizes are adjusted to suit. He postulates that mechanical friction is rising so steeply at 14-15,000 revs that it eats any power gains. Some interesting research supports his view. Pistons are not ideal sliders at high speed, and crank journal oil films can all but disappear under heavy inertia load, leaving only higher-friction oil additive films to carry the freight. There is evidence that extremely hard surface coatings are being used in Formula One engines, to deal with such issues. Although interesting, this kind of thing is hardly a magic bullet.

“The heart of the matter is the engine. Our curiosity focuses on how it aims to achieve something the Japanese have not already.”

The central distinguishing feature of the F4 engine is its combustion chambers. The traditional four-valve combustion chamber has a rectangular roof form, but the expanding combustion flame is more nearly circular. This has stimulated a search for a À T T O HP A more circular com^ ^ liV bustion space. The

H solution adopted for the Agusta is radial valve arrangement. The stems of all four valves tilt slightly (at 11 degrees) away from the axis of the cylinder. Where the traditional four-valve has two sloping “roof’ surfaces, the radial-valve chamber has four. This concentrates charge closer to the sparkplug, potentially accomplishing two things: 1) At any given flame travel distance, more of the charge has been reached and bumed-this can speed combustion through geometry; and 2) volume concentrated near the plug provides room in which charge turbulence can continue to move-it is not so quickly damped out by the close approach of the piston to the head. This can speed combustion through turbulence.

Note my usage of the word “potentially.” The reason is that the F4 engine currently requires more than 45 degrees of ignition advance at peak power. This large number indicates that the F4’s combustion is not yet very speedy. Compare that number with the Kawasaki’s spark lead, which is under 40 degrees. That, in turn, suggests that further development may extract significant gains from this engine.

Each time Japanese makers have shortened the strokes of their 750cc Fours, it has created combustion problems. For Suzuki in 1988, this meant going back to its longer, pre1988 stroke. When Kawasaki shortened its 750’s stroke recently, it took two years just to equal the power of the previous engine. Making the F4 work well with the largest bore/stroke ratio of all 750s has probably not been easy, and the job isn’t finished.

Will radial valves make the F4 superior? The hard fact is that design features are often less important than development, but radial valves could make a difference. Honda has used them on its big off-road Singles, and radial valves do allow these engines to bum with less ignition advance. That translates to power.

Cagiva’s press-release specifications claim 125 crankshaft bhp for this engine, given at 12,200 revs, with peak torque of 53 foot-pounds at 9000 rpm. But that set of numbers has been replaced with fresh news straight from the dyno room. The new figures are 128 crankshaft bhp at 12,500 rpm, with peak torque of 55.6 ft.-lb. at 11,000. What can we make of these numbers? The first pair is impressive because of the large spread of 3200 revs between peak torque and peak power (compare that with the current GSX-R750 Suzuki,

with its two peaks 2200-odd revs apart). This suggests an easy-to-ride, tractor-like engine. But the new figures separate torque and power by a supernarrow 1500 revs, indicating a top-end monster.

How do we resolve the matter? It is just this: We are looking into the dyno room at a time when basic specifications are constantly changing as engineers look for an optimum spec. Neither set of numbers is final because big questions are still under discussion.

An engine with a wide torque spread is pleasant to ride, and if enough high-rpm power can be combined with it, it satisfies the criterion for good Superbike potential-a tractor with top-end. The 128-bhp version is reaching for bigger numbers, and paying a price in narrower torque spread.

How are the radial valves operated? Although some radialvalve engines have been mechanical nightmares, this one is simple. Conventional invertedbucket tappets are used, and the cam lobes themselves are ground at an angle to accommodate the angled valves. There are two camshafts, one exhaust, one intake, as in a pentroof engine. The concept comes from the late Ludwig Apfelbeck, the Austrian engineer who devoted his life to its elaboration, building countless prototypes for various engine manufacturers.

One potential problem of a high-speed, very short-stroke engine is compression. A high compression ratio is desirable because it boosts torque, but it also makes the combustion chamber tighter and, maybe, slower-burning. A point can be reached at which a choice has to be made. The tight, highcompression chamber bums poorly at high speed because turbulence can’t last long enough inside it to assist combustion. Therefore, top-end power fades. To recover top-end, compression ratio can be reduced, but this hurts bottom-end and midrange power. Pick your compromise-neither is attractive. The F4’s compression ratio is currently 12:1.

With radial valves, this compression compromise might potentially be broken. The radial valve chamber is like a very shallow teepee, tall and roomy right under the central sparkplug. With more of the charge closer to the plug, compression ratio can be pushed higher before the compromise begins to hurt badly. The resulting engine can be strong across its whole rpm range.

“What are the effects of radial valves on airflow? Why six main bearings when others have worked so hard to eliminate as many as possible? ”

Much of this is like debating the best design for a shovel. It’s not until you get down in the hole and start digging that you truly know what you need. The first part is design. The second is developT" mentThis engine ment. This engine has been designed in cooperation with engineers at Ferrari, and has been through several iterations.

The wet-sump engine shares lubricant with the gearbox, installed as a cassette. A cassette gearbox is normally a feature only of pure racing engines. Its purpose is to allow the entire gear cluster and selector mechanism to be withdrawn endwise from the case, without engine removal or crankcase splitting. Here’s how it’s useful: In a certain turn, a rider finds himself having to accelerate with his engine 200 revs under its torque threshold, and shifting down would over-rev it. In half an hour, his mechanics pull the gear cluster and exchange that ratio for another that turns the engine 200 rpm higher. Nice. Every bike in GP racing has this feature, but currently, no Superbikes do.

The engine is barely wider than its cylinders alone, for the starter mounts ahead of the crank, while the alternator is carried behind, atop the gearbox. Camdrive is by central chain, so there are six main bearings. These are lubricated conventionally, from a main galley parallel to the crank, supplying the mains. Oil is taken by paired drillings from main journals numbers 2 and 4, such that each one supplies oil to the two adjacent crankpins.

The steeply inclined intake stacks resemble those of the new Suzuki GSX-R750 in that they contain butterfly throttles and one electronic fuel injector per cylinder.

Cooling is by curved radiator, which fits more core surface into a given fairing width. Through an oil-to-water heat exchanger, this radiator also cools the 3.7 quarts of oil carried in the engine.

Intake air enters ducts beneath the stacked headlights, passes through intake silencers, and enters a large-volume airbox mounted above the intake stacks, under the fuel tank. Airbox, tank and coolant-expansion tank are integrated. Care is taken to prevent intake air from “rotating” in the airbox-ever notice how slowly fuel runs through a funnel if it begins to swirl?

Exhaust is routed in torque-smoothing 4-2-1 style to a pair of silencer units mounted under the rider’s seatback, and exits through four round exhaust tips. The silencer is of the tuned-resonator type, which passes desired frequencies but suppresses unwanted ones. The exhaust sound of the F4, it appears, is as carefully designed as any physical component. This component is still under development.

Some questions about the design remain. What are the effects of radial valves on airflow? Why does this design have six main bearings when Japanese engineers have worked so hard to eliminate as many as possible? The answers to these and others will result from the encounter of this new engine with World Superbike.

The highly visible upper fork crown is polished on top, and of open-webbed design beneath. The lower crown is of very stiff box construction. Steering-head angle is adjustable by means of patented eccentric bearing carriers. Consequently, no rake angle is quoted, but trail is given as a substantial 4.08 inches. The steeringhead itself is a thinwallsteel casting, welded to the tubular structure. The steering damper mounts transversely behind the steering head, operated by a connecting rod to the upper crown.

The thinwall, tubular front axle is of 35mm diameter, as this gives great stiffness and low weight. Such large axles have been the norm in GP racing for many years, but are now making their way into production vehicles. The rear stub axle is forged steel, of 50mm diameter. Chain adjustment is made by an eccentric axle carrier in the swingarm. Wheels are 3.5 x 17-inch front, 6.0 x 17 rear, carrying a 120/65-ZR17 front tire and a wideweenie 190/50-ZR17 out back.

Now more food for thought: Claimed top speed is 275 clicks, which converts to 171 mph. That claimed 125 horsepower? By the time the ponies file past two gear reductions and the chain, that will become more like what we expect from a strong-running GSX-R750, which is reasonable. So is the top speed. Daytona trap speeds for 750 Supersports are in the lowto mid-160s, and would be higher if there were more room to accelerate. It all fits and makes acceptable sense.

Why pay glamour prices ($28,000 is the figure being bandied about) for numbers available next door for less? If you have to ask, you’ll never know. One of the few good reasons for being wildly, embarrassingly rich is to be able to have something beautiful and outrageous like this just because you want it. Which is the very reason Count Agusta created the original MVs in the first place. □

View Full Issue

View Full Issue