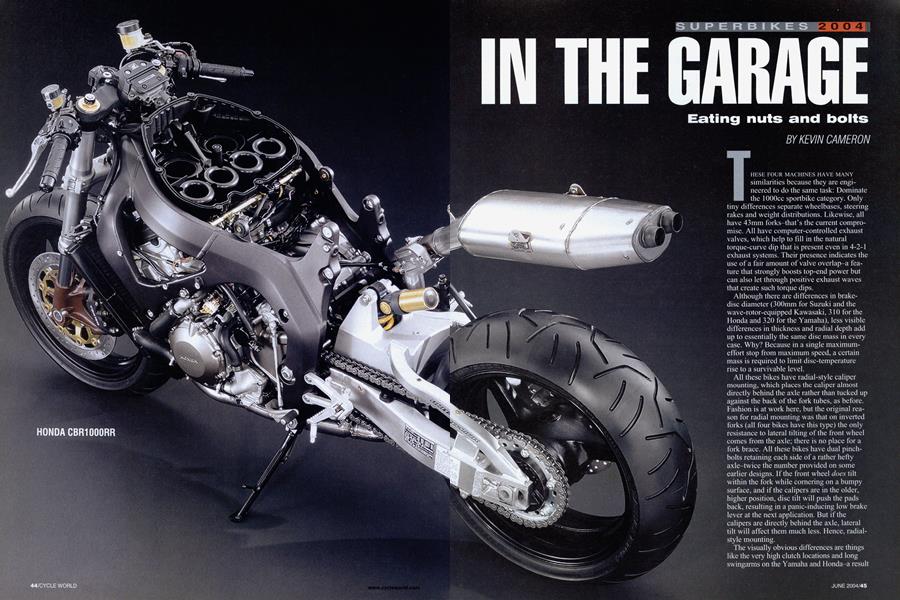

HONDA

CBR1000RR

IN THE GARAGE

Eating nuts and bolts

KRVIN CAMERON

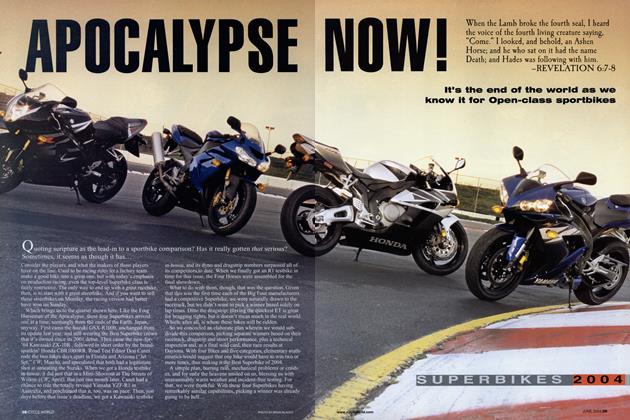

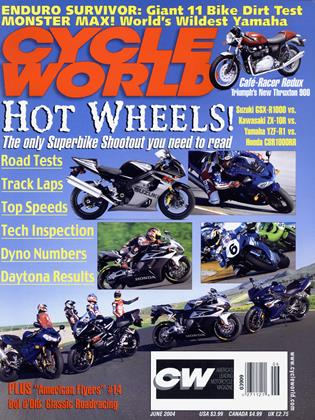

THESE FOUR MACHINES HAVE MANY similarities because they are engineered to do the same task: Dominate the 1000cc sportbike category. Only tiny differences separate wheelbases, steering rakes and weight distributions. Likewise, all have 43mm forks-that’s the current compromise. All have computer-controlled exhaust valves, which help to fill in the natural torque-curve dip that is present even in 4-2-1 exhaust systems. Their presence indicates the use of a fair amount of valve overlap-a feature that strongly boosts top-end power but can also let through positive exhaust waves that create such torque dips.

Although there are differences in brakedisc diameter (300mm for Suzuki and the wave-rotor-equipped Kawasaki, 310 for the Honda and 320 for the Yamaha), less visible differences in thickness and radial depth add up to essentially the same disc mass in every case. Why? Because in a single maximumeffort stop from maximum speed, a certain mass is required to limit disc-temperature rise to a survivable level.

All these bikes have radial-style caliper mounting, which places the caliper almost directly behind the axle rather than tucked up against the back of the fork tubes, as before. Fashion is at work here, but the original reason for radial mounting was that on inverted forks (all four bikes have this type) the only resistance to lateral tilting of the front wheel comes from the axle; there is no place for a fork brace. All these bikes have dual pinchbolts retaining each side of a rather hefty axle-twice the number provided on some earlier designs. If the front wheel does tilt within the fork while cornering on a bumpy surface, and if the calipers are in the older, higher position, disc tilt will push the pads back, resulting in a panic-inducing low brake lever at the next application. But if the calipers are directly behind the axle, lateral tilt will affect them much less. Hence, radialstyle mounting.

The visually obvious differences are things like the very high clutch locations and long swingarms on the Yamaha and Honda-a result of their up-to-date “stacked” gearbox shaft arrangement. I suspect Yamaha needed to adopt this feature because its signature, 40degree inclined cylinder block pushes the crankshaft back from the front wheel (crankcenter to front-axle-center distance is the largest of the four bikes). This gave engineers a need to concentrate engine/gearbox mass farther forward to achieve the forward weight bias necessary to keep front wheel lift from making the bike run wide during offcorner acceleration.

Stacking the gearbox shafts achieves this-and places the clutch in a non-traditional position, 3-4 inches high er than in bikes with both shafts in the same horizontal plane. With the gearbox output shaft thus moved forward, a longer swingarm can be used at a given wheelbase-the Yamaha and Honda arms are 231/4 and 23 3/8 inches long as compared with 221/2 and 211/2 for the Kawasaki and Suzuki, respectively.

As you may have noticed, longer swingarms have been a trend in racing for some time-the obvious example being the long line of Honda NSR500s. The longer the swingarm, the easier it is to manage the lift/squat forces generated by chain-pull, which can easily exceed a ton in lower gears.

All of these engines have fuel-injection-carburetors are heirlooms now. Only a fuel system that can be controlled in an agile manner by digital logic can duck and weave past the EPA to deliver smooth, non-sputter-and-stall power.

SUZUKI GSX-R1000

YAMAHA YZF-R1

I was surprised by what packaging has achieved on these machines, and am encouraged to believe that as sterner measures are required for emissions abatement, there will be room for whatever is necessary. Yamaha has achieved its underseat muffler location by routing the collector up through the swingarm, while Honda’s similar result is implemented by jog-

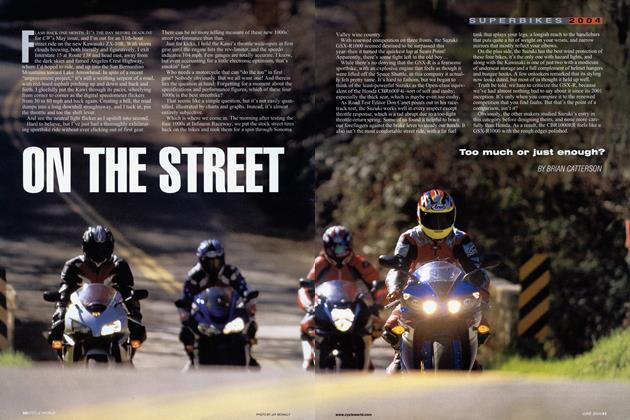

gling the right-hand swingarm beam inward for collector clearance. The Kawasaki and Suzuki have conventional muffler location, upswept on the right. Pick the style you like—I doubt there’s any performance advantage either way. And now to the substance of my narrative: For years, it was clear that the stiffer the chassis, the better use could be made of increasingly sticky tires. As a result, 500cc Grand Prix bikes developed mighty chassis side beams and their steering heads were heavily sheeted-in to create structures that were almost marine in their massiveness. This was progress. Meanwhile, little voices uttered the blasphemy that some chassis compliance was necessary to provide lateral flexibility to act as a suspension when the machine was leaned far over in turns. The usual racing response to choppy comer surfaces was to fit forks with smaller tubes^43mm instead of stiffer 46s or even 50s. Meanwhile, every maker was devising rigs in which the nature of chassis flex was evaluated. It was soon clear that the desirable result was some ability of the wheels to move sideways in response to small bumps, but with no tilting out-of-plane which could set them wiggling just as suddenly twisting a gyroscope does.

The first visible result of this was differently proportioned swingarms, the side beams of which were very deep vertically, but fairly thin laterally-now fairly common in racing. These allow the rear wheel to deflect sideways to accommodate small bumps in comers, but keep it in plane.

Aha! The current novelty is much less visible, but is perhaps nonetheless effective. When you look at the forward part of the Honda’s chassis, you see a vast region of blackpainted metal, apparently bracing the steering-head against every motion. This is just what you see on the Kawasaki-a fine example of classic GP chassis design with its massively braced steering head attaching to the engine’s head and cylinder in many places.

When you lift the tank and remove the side “accent strips” from the Honda, however, a different picture emerges. Its steering head is like a quadruped, perched over the engine on longish legs that are actually quite thin laterally. This is where Honda’s RC21IV MotoGP bike has most influenced the CBRIOOORR’s design (and not in all that nonsense about Unit Pro-Link “re-directing chassis energy”). I suspect that this steering head design does for front suspension what the above described laterally compliant swingarms do for the rear-it allows small bumps to push the front wheel, fork and steering head sideways enough to deal with them effectively. The Honda’s steering head links not to the nearby head and/or cylinder, but more distantly to the cases. The same is true of the RC21IV. The extra length and lateral thinness of the four struts supporting the steering head provide this notional flexibility.

This is speculation on my part, and industry engineers may chuckle if they read these words. On the other hand, we know that some kind of incomer “lateral suspension” is a real need in racing. It would be very strange if no one were doing anything about it.

Yamaha has used its thin-wall casting process in the continuing battle against weight. It also helps hold the price line by reducing the number of welds necessary. Kawasaki has brought the most power to this category-always an impressive achievement, and I hope a step back toward the performance reputation the green machines created more than 30 years ago. Suzuki’s GSX-R is the proven workhorse of lOOOcc sportbikes-e very thing works well, and this year’s dramatic Daytona win adds emphasis. I feel like I’ve been asked to review four delicious ice creams-I want to eat them all. From the standpoint of new technology, however, I’m drawn to Honda’s unique steering head. It is an attempt to overcome the chronic problems of high-powered machines when ridden hard: chatter and lack of front-end feel. Only continuing experience will show whether it works as I think it does.

TRAIL

ADVANTAGE: HONDA

KAWASAKI ZX-10R

View Full Issue

View Full Issue

More From This Issue

-

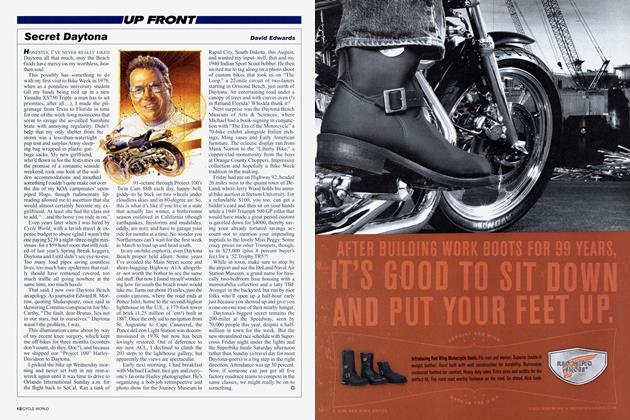

Up Front

Up FrontSecret Daytona

JUNE 2004 2004 By David Edwards -

Leanings

LeaningsWhat To Do In Winter

JUNE 2004 2004 By Peter Egan -

TDC

TDCA Short History of Chassis Flex

JUNE 2004 2004 By Kevin Cameron -

Departments

DepartmentsHotshots

JUNE 2004 2004 -

Roundup

RoundupMonster Max!!!

JUNE 2004 2004 By Steve Anderson -

Roundup

RoundupFormula Bmw: K-Bike Power For F-1 Hopefuls

JUNE 2004 2004 By Kim Wolfkill