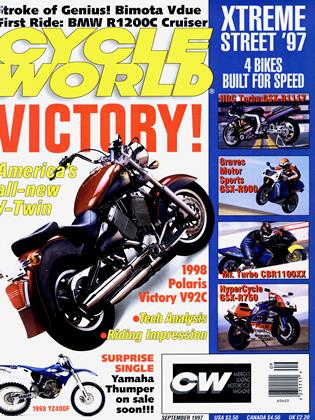

Victory!

POLARIS UNVEILS ITS CRUISE MISSILE

KEVIN CAMERON

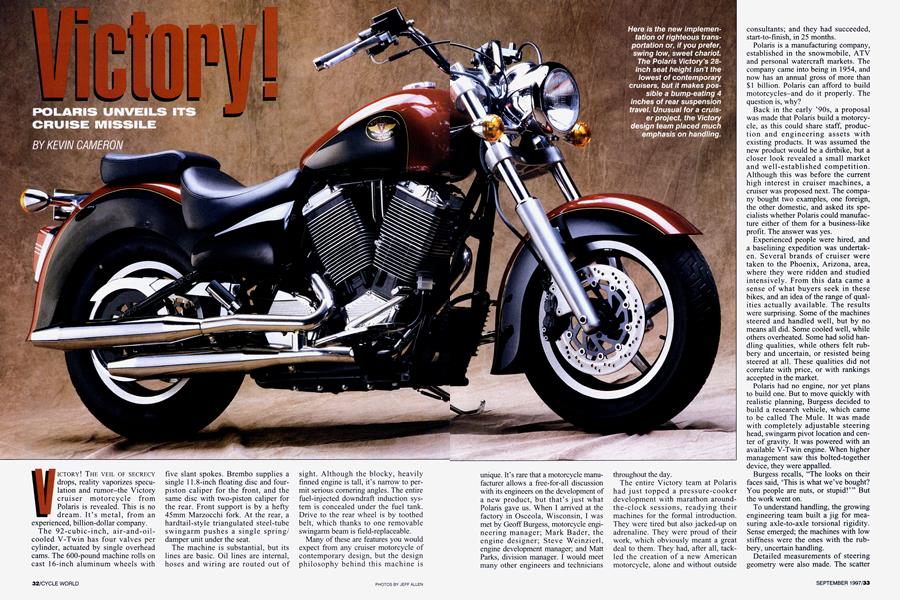

VICTORY! THE VEIL OF SECRECY drops, reality vaporizes speculation and rumor-the Victory cruiser motorcycle from Polaris is revealed. This is no dream. It’s metal, from an experienced, billion-dollar company.

The 92-cubic-inch, air-and-oil-cooled V-Twin has four valves per cylinder, actuated by single overhead cams. The 600-pound machine rolls on cast 16-inch aluminum wheels with five slant spokes. Brembo supplies a single 11.8-inch floating disc and fourpiston caliper for the front, and the same disc with two-piston caliper for the rear. Front support is by a hefty 45mm Marzocchi fork. At the rear, a hardtail-style triangulated steel-tube swingarm pushes a single spring/ damper unit under the seat.

The machine is substantial, but its lines are basic. Oil lines are internal, hoses and wiring are routed out of sight. Although the blocky, heavily finned engine is tall, it’s narrow to permit serious cornering angles. The entire fuel-injected downdraft induction system is concealed under the fuel tank. Drive to the rear wheel is by toothed belt, which thanks to one removable swingarm beam is field-replaceable.

Many of these are features you would expect from any cruiser motorcycle of contemporary design, but the design philosophy behind this machine is unique. It’s rare that a motorcycle manufacturer allows a free-for-all discussion with its engineers on the development of a new product, but that’s just what Polaris gave us. When I arrived at the factory in Osceola, Wisconsin, I was met by Geoff Burgess, motorcycle engineering manager; Mark Bader, the engine designer; Steve Weinzierl, engine development manager; and Matt Parks, division manager. I would meet many other engineers and technicians throughout the day.

The entire Victory team at Polaris had just topped a pressure-cooker development with marathon aroundthe-clock sessions, readying their machines for the formal introduction. They were tired but also jacked-up on adrenaline. They were proud of their work, which obviously meant a great deal to them. They had, after all, tackled the creation of a new American motorcycle, alone and without outside consultants; and they had succeeded, start-to-finish, in 25 months.

Polaris is a manufacturing company, established in the snowmobile, ATV and personal watercraft markets. The company came into being in 1954, and now has an annual gross of more than $1 billion. Polaris can afford to build motorcycles-and do it properly. The question is, why?

Back in the early ’90s, a proposal was made that Polaris build a motorcycle, as this could share staff, production and engineering assets with existing products. It was assumed the new product would be a dirtbike, but a closer look revealed a small market and well-established competition. Although this was before the current high interest in cruiser machines, a cruiser was proposed next. The company bought two examples, one foreign, the other domestic, and asked its specialists whether Polaris could manufacture either of them for a business-like profit. The answer was yes.

Experienced people were hired, and a baselining expedition was undertaken. Several brands of cruiser were taken to the Phoenix, Arizona, area, where they were ridden and studied intensively. From this data came a sense of what buyers seek in these bikes, and an idea of the range of qualities actually available. The results were surprising. Some of the machines steered and handled well, but by no means all did. Some cooled well, while others overheated. Some had solid handling qualities, while others felt rubbery and uncertain, or resisted being steered at all. These qualities did not correlate with price, or with rankings accepted in the market.

Polaris had no engine, nor yet plans to build one. But to move quickly with realistic planning, Burgess decided to build a research vehicle, which came to be called The Mule. It was made with completely adjustable steering head, swingarm pivot location and center of gravity. It was powered with an available V-Twin engine. When higher management saw this bolted-together device, they were appalled.

Burgess recalls, “The looks on their faces said, ‘This is what we’ve bought? You people are nuts, or stupid!’” But the work went on.

To understand handling, the growing engineering team built a jig for measuring axle-to-axle torsional rigidity. Sense emerged; the machines with low stiffness were the ones with the rubbery, uncertain handling.

Detailed measurements of steering geometry were also made. The scatter was large-head angles ranged from 26 all the way to 32 degrees. Trail also varied widely. From the data, ideas of how to provide light, stable steering emerged. They were promptly tested on The Mule.

“We got the old dots on there,” said Burgess, referring to plotting this data. The plot gave them not only a good chassis setup for a cruiser, but numbers

for other levels of steering responsiveness-a sportier cruiser, and an unnamed variant, obviously a potential sportbike concept. All of this work was made possible by The Mule’s adjustability, with the use of appropriate wheels and brakes.

Meanwhile, an engine design team was assembled. To avoid wasting time, these men began at once to create an “encyclopedia” of design parametersnot just for this engine, but for any possible future designs. They intended to create a reference tool that would allow quick, fairly accurate estimates on any aspect of design. This was implemented in Mathcad programs, available instantly to any engineer on the Polaris network. They were greatly helped in this by the man who, more than any other, had persuaded Polaris management that the company should tackle this project in the first place: Martin Heinrich.

In 1991, Heinrich came to Polaris from Kohler, where among other duties he had designed engines for the Mercury SnoTwister snowmobiles. At Polaris, he pushed what came to be the company’s Domestic Engine Program, in which advanced two-stroke engines were designed, sourced and built entirely in the U.S. The success of this program made the Victory engine possible.

To get a prototype running as soon as possible, Bader (also ex-Kohler) decided to CNC-mill crankcases from massive 300-pound aluminum billets, resulting in a test engine they called The Hammer. I was shown the bare cases of this behemoth, and it was all one man could do to drag them across the floor! With tool-room components like milled-from-billet con-rods, a prototype was brought to life and engine testing began.

This is the information age, when advanced products are simulated and designed on-screen, using computeraided design and manufacturing (CAD/CAM). Bader addressed his engineers: “You are engineers, not tube jockeys. ProE and the computers are just tools. You have to make the decisions.” ProE is a 3-D design/modeling program, and Bader was cautioning his colleagues against falling into the feeling that the computer can design engines-only humans can do that.

At the software shows, salespeople demo the ability of dynamic FEA (Finite Element Analysis) programs to locate stress concentrations and predict vibrational modes. But how do you

model a layer of RTV or a gasket in a case joint? The Polaris engine team had to find its own answers. As Burgess said, “The story of CAD is this: The complicated things become simple, and the simple things become complicated.” Bader added, “There are all these wonderful codes for predicting everything, but how can you be sure the result is reasonable? You always have to ask the question, ‘Does this make sense?’ ”

“To be a good designer, you also have to be a historian,” Weinzierl noted, pointing to the many valuable and still pertinent lessons to be learned from studying existing designs and how they grew.

Why design the engine themselves? Why not just buy a design from one of the recognized design houses-Ricardo,

Porsche or TWR? “We decided we were going to do it ourselves,” Bader said. “What’s the sense of hiring someone else to do it for you? Then you know nothing about what you’ve bought, and you can’t fix the design if it ever needs it.”

In 15 months, they had a running engine.

A major task was defining key positions and dimensions. From focus groups came the idea that the engine/ transmission should have a long look, but it wouldn’t fit into the proposed 63-inch wheelbase. Engine length was cut, and the Vee angle was reduced to 50 degrees to make the powerplant more compact. Fifty degrees, incidentally, is the angle chosen by Glen Curtiss for his pioneering Twin of 1903.

Next, the squat/anti-squat relationship between swingarm pivot height and engine sprocket location had to be tested and defined. This, and the choice of engine height, defined shaft positions.

It was an experimental approach; choose the variables that are important, research their effects, then use the results to define the design. Engineer to specification. This motorcycle, they were determined, would be knowledgebased. It wouldn’t be a copy of anything, even remotely. Every important feature would be the result of thought, not of blind tradition or of dictation from some remote styling concept.

It’s more remarkable that management let it happen. Obviously, Polaris management had trusted its engineers before, and hasn’t been sorry. This is how it should be in a rational world.

The test engine made mighty torque. Bader tells o♦f standing in the Froude dyno cell with The Hammer, thundering at peak power, 5700 rpm. The headers were glowing dull-red and the noise was terrific. That night, Bader told his wife, “I spoke to God today.”

How should the engine be balanced? Is there such a thing as “good vibration?” Could it be defined? This was important because the need for chassis stiffness suggested that the engine be rigidly mounted. If there were too much vibration, this would be impossible. The Victory engine design includes a gear-driven intermediate shaft, between engine and gearbox. By placing counterweights on this shaft, both up-and-down and fore-and-aft components of primary imbalance could be adjusted to any value. But what value, and in which direction? With astrophysicist-turned-bike-engineer Robin Tuluie assisting with calculations, one engine was made with primary vibration zeroed out, leaving only the double-frequency secondaries. Everyone thought this felt odd. Math models were made and hardware tests run to find a balance combination that gave, in the words of Parks, “that lulling Twin feel.”

Both the physical and the subjective go into a motorcycle’s appeal. What’s not obvious is that every single point has to be decided by someone. When and where does the maximum sub-surface stress occur in cam lobe and tappet face? How big should the oil pump be to ensure that, with a hot engine, hydraulic tappet leakdown can never occur?

The engine has excellent combustion. When I asked if parts of its ignition map were under 30 degrees of advance, Bader and Weinzierl replied with a whoop, “Most of it!” This is good, because rapid combustion is efficient, allowing most of the fuel-air charge to burn with the piston close to the cylinder head, at the highest effective compression ratio. Bader explained, “I think it has short-stroke tumble in a long-stroke engine.”

Tumble is rotary charge motion in the same sense as crank rotation, and it is natural to four-valve designs. A long stroke gives plenty of room above the piston at TDC for the continuance of vigorous charge motion, and it’s this that gives the Victory Twin its rapid combustion. There is so much room above the piston that this is a so-called “free-spin” engine; even if the cams are mistimed, or a tremendously worn camchain jumps teeth, the valves cannot hit the pistons.

We threaded our way through giant parts and production buildings to the R&D shop, with Bader producing keys at each door marked, “Authorized Personnel Only.” Here, we saw the prototypes-one a finish-painted runner for the official intro two days hence, the other a well-worn development hack. Between them was a Victory sidecar rig, loaded with electronics. This was a major tool in the bike’s fuel-injection development. The processor is by the English MBE firm, with injectors and other parts from other vendors.

Bader noted wryly, “When we cranked the engine the first time, it started and ran. We had no idea then how lucky we’d been, until after we’d learned more about fuel injection.”

Injection is not, evidently, the simple matter of typing in what you want and

then enjoying its prompt delivery by obedient hardware. What works on the dyno may not work on the road. There are endless glitches—little hesitations in acceleration, for instance-that only occur under special circumstances. Every one had to be tracked down and reproduced on the sidecar bike, while the MBE engineer/passenger stared at the screen in hopes of identifying a cause. Burgess said that during this process he yearned for the simplicity of carburetor jets!

Cams were ground with 215, 235 and 250 degrees duration, and the engine gave best power with the 215. This is another component of mighty torque; the shorter the cam timing, the less the piston will back-pump its charge at lower rpm, resulting in more charge trapped. If a short-duration cam gives good peak power, that’s good news for bottom-end power, which thrives on short duration.

Hefty webbed aluminum fork crowns support the twin Marzocchi fork legs. Marzocchi engineers had at first dismissed Polaris’ request for 45mm tubes. “What do you need such big tubes for?” company officials asked. When they saw the bike, they understood. This fork looks right on the machine-and more importantly, its stiffness contributes to reaching the chassis torsional stiffness the team wanted.

A cylinder head was brought into the conference room. Its single chain-driven cam sits beneath a pair of rocker shafts, each of which carries a forked roller rocker, activating two of the four valves. The cam is short, permitting the centrally located sparkplug to sneak in at an angle, residing in an Oring-sealed tube in Hemi-Chrysler fashion. At one side is the space in which the camchain runs. On the outside of the boxy-but-light casting are closely spaced fins. “They’re not just decoration,” said Bader. “They contribute a significant amount of the cooling.”

Turning the head over, I could see the cored passages for cooling oil, which completely surround the cylinder head. It looks, in fact, just like a liquid-cooled head. Later, another remarkable article was brought in-a cylinder “made” on one of the new rapid-prototyping machines. This one was made of paper, laser-cut to outline under computer control, then automatically stacked up and bonded layer by layer to make a remarkable 3-D representation of a finished part. When purchase of this machine was first proposed, there was resistance. But the ability to tum a computer file quickly and directly into something that engineers can handle, talk about and test-fit to other parts has now solved so many problems that a second such machine is on the way.

The real cylinders have 97mm Nikasil bores, and are oil-jacketed in their upper portions. Pistons are modem, short-skirted slipper designs, light and strong. Rods are steel. Bader notes that when he initially dimensioned the rods, he began with 204mm, which is twice the stroke length-a standard choice. But with these rods and the long stroke, the engine was again trying to outgrow the chassis. Shorter rods were chosen. Another problem developed. It was the same problem that confronted auto-engine designers in fitting big-block V-Eights into passenger cars; with a 2:1 rod ratio, engine width would make exhaust pipes impossible.

As a first choice, Bader gave the throttle body 40mm bores. But tests showed that the engine liked 44mm throttles better. “The engine is the ultimate authority,” he said. Polaris buys huge volumes of aluminum extrusions for its snowmobiles, so these dual throttle bodies will be extruded and cut to length. The injectors mount directly onto pads on the heads, aimed at the backs of the intake valves. Each cylinder has a steep downdraft induction stub, making a close vertical pair with the heads in place on the engine. Possible problems of leakage or relative motion in joining to the throttle body are solved by a flexible, moldedrubber junction block.

“May I see a crankshaft?” I asked in the prototype shop. Bader rummaged in boxes and emerged with a crank. It’s a cast full-circle wheel pair, and turns in plain, replaceable shell bearings, pressed into the monumental, vertically split cases. The major aluminum parts of this engine are sand-cast in the proven 356 alloy, which made up so much of wartime aircraft engines.

Feel remained the focus of much effort throughout design. How should shifting feel? The engineers tested a variety of shift-drum detent stars to get what they wanted. How should brakes feel to give confidence as well as to reliably stop the machine? How should the clutch pull feel? As far as possible, these things were quantified.

Power from the crank passes by gears to the intermediate shaft, whose left end carries a cam-and-ramp torsional absorber, while its right end drives the dual Gerotor oil pumps, one for lube, the other for cooling. Scissors gears take care of the variation in tooth-totooth clearance that occurs as aluminum cases expand during warm-up. These gears have the extra-long “highcontact-ratio” tooth form favored for noise reduction. A very large-diameter multi-plate clutch is geared to the intermediate shaft, feeding power to a fivespeed unit gearbox. Everything is lubricated and cooled by 6 quarts of oil, carried in an integral sump under the engine. A 10-gallon-per-minute flow rate through a low-mounted oil cooler positively controls engine temperature.

A myriad of parts, an equal number of choices, each backed by study and refinement. Now, these parts amount to a useful machine.

The Victory V92C was revealed to the press on June 26, 1997, and it is impressive. But looming in the background is the larger creation of the hard-working Polaris engineers: namely, their engine and chassis design capability. It will be interesting to see where this talented team turns its energy next. □

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsUp Front

September 1997 By David Edwards -

Columns

ColumnsLeanings

September 1997 By Peter Egan -

Columns

ColumnsTdc

September 1997 By Kevin Cameron -

Letters

LettersLetters

September 1997 -

Roundup

RoundupAt Last! Bimota's Two-Stroke Hits the Street

September 1997 By Alan Cathcart -

Roundup

RoundupSpied! New Yamaha Superbike

September 1997