HONDA EXP-2

new-wave combustion

KEVIN CAMERON

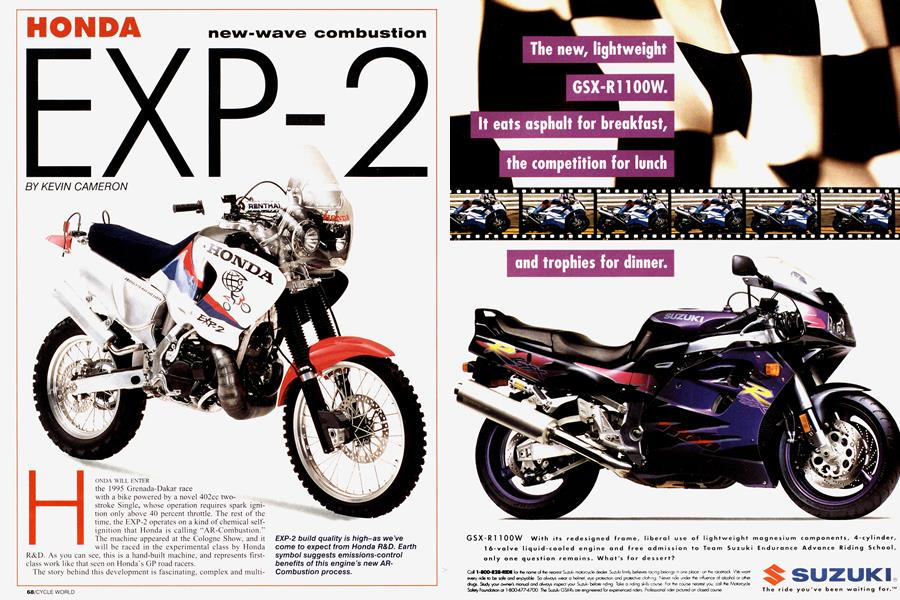

HONDA WILL ENTER the 1995 Grenada-Dakar race with a bike powered by a novel 402cc two stroke Single, whose operation requires spark ignition only above 40 percent throttle. The rest of the time, the EXP-2 operates on a kind of chemical self-ignition that Honda is calling "AR-Combustion." The machine appeared at the Cologne Show, and it will be raced in the experimental class by Honda R&D. As you can see, this is a hand-built machine, and represents first-class work like that seen on Honda’s GP road racers.

The story behind this development is fascinating, complex and multinational. It begins in the 1930s with uncompleted research at MIT, and with theoretical work by the many-sided Soviet physicist Ya. Zel'dovitch, later one of the big three of Russian A-bomb developers. It is related to the combustion system of the German VI “buzzbomb” of WWII. The concepts behind the EXP-2 are so counter to established thought that 1970s reports on them by workers at Toyota and the Japan Clean Engine Institute were at first turned down by the American Society of Automotive Engineers, and were finally published only after personal sponsorship by Mercury Marine’s openminded Ben Schaefer.

AR stands for Active Radicals, which are chemicallyactive molecular fragments produced by partial combustion of fuel. AR-Combustion can operate without spark ignition by seeding the engine’s fresh charge with such active fragments, intentionally carried over from the previous engine cycle. With chemical change in the mixture now accelerated by this seeding, and helped by the heat of compression, self-ignition is achieved at some point during the compression stroke.

Paradoxically, the active radical action Honda uses to fire the EXP-2 is also the cause of detonation, the major limiting factor in spark ignition engine design. Small wonder, then, that most engineers have ignored this research.

At room temperature, mixtures of gasoline vapor and air are stable-otherwise we'd be blown up every time we opened our gas caps. But as the temperature of such mixture is raised-for instance by the heat of an engine’s compression stroke-there begin what are termed “pre-flame reactions,” slow breakdown of fuel molecules, accelerating as temperature rises. Some of the resulting fragments, often combined with oxygen from the air, are the active radicals mentioned above—chemical species with unpaired electrons that enable them to react readily with remaining fuel molecules, accelerating further breakdown.

In a traditional spark-ignited engine, these pre-flame reactions speed up sharply once the spark initiates actual combustion. As the flame front pushes across the chamber, it acts like a piston that compresses and heats the unburned charge remaining ahead of it. This unburned charge is meanwhile breaking down rapidly into active molecular fragments-even though the flame front hasn’t yet reached it. If this breakdown process continues long enough, and at high enough temperature, these reactions in the unburned mixture release heat so fast that it achieves “hot ignition”—it goes off by itself, or auto-ignites. This unburned end-gas is now mostly unstable fragments, such that it can no longer burn normally and smoothly. Instead, it explodes, generating a shock wave that is heard as engine knock, which damages or destroys parts. Note carefully that this violent auto-ignition is set off by active molecular fragments, which heat has generated in the end-gas, before the arrival of the normal flame front.

Traditional engine research has sought to prevent knock by two major means; chemistry and faster combustion. Chemists create high-octane fuels that strongly resist the pre-flame reactions that can lead to knock. Because these reactions take time to develop, knock can also be avoided by speeding up combustion with turbulence, to burn the charge up before any part of it can reach the point of knocking.

Knock is just one of the possible forms of radical-initiated combustion-a violent and destructive one. There is another. Have you ever seen a two-stroke engine run away, revving madly, and then continue to shriek right off the tach after the plug wires have been pulled? Lots of us have, and it’s an impressive event. It happens only under peculiar conditions of low load and throttle. Most of us have dismissed the whole thing, mumbling about “dieseling.” Few researchers and theoreticians have investigated how this happens, and now Honda has chosen to introduce it to the world as a new combustion process.

Such an engine runaway is not true diesel operation. The diesel cycle operates by compressing air until it is so hot that fuel injected into it is immediately ignited. The compression ratio of spark-ignition engines is never high enough to heat air to the fuel’s flash point.

What is actually making the runaway engine run is active radical action. At low throttle, there is little cool fresh charge entering the cylinder, so any active radicals left from the previous cycle are neither flushed out nor cooled significantly. Seeded with active chemistry in this way, resulting mixture has a very low ignition energy requirement. Its chemistry is already on its way as compression begins, so that even moderate compression may be enough to push the reaction all the way to hot ignition. Put another way, the mixture’s flash point is greatly reduced by the presence of the chemical radicals. In the German buzzbombs, the charge was pushed to hot ignition by the pressure waves in the engine duct. In the runaway piston engine, normal compression does the same job.

In earlier work done in the 1970s, engineers could make engines run on radical-initiated ignition, but only at constant speed and load. Honda has obviously researched this phenomenon and mapped out the regions in which AR-operation is or is not possible. It has discovered that the key to this is to control the pressure of the mixture at the start of compression. The denser the charge, the earlier the engine fires, and vice versa. Control is achieved by placing a valve in the exhaust port that manages the proportions of fresh charge and exhaust left-over in the cylinder.

Clearly, if Honda plans to use this process on an rallybike engine, it is confident that the controls can keep up

with the vigorous throttle motion necessary in competition. Honda has revealed that this machine employs the PGM-FI electronic fuel injection, but that the process doesn't depend upon it; a carburetor could be used just as well. Very likely, injection is used on the EXP-2 simply because some computing power and memory is required to control the AR valve in the exhaust, and the PGM computer provides this. In research presented to the French Petroleum Institute a year ago, Honda stated that its 250cc research engine (was this the “EXP-1?”) operated on AR-Combustion below about 40 percent throttle, but switched to conventional spark ignition for higher throttle and for starting.

Why bother? The potential payoff is three-fold; knockfree operation even on low-octane fuels, exhaust emissions are reduced and efficiency is raised in terms of horsepowerhours per pound of fuel burned.

How can it operate without knock when AR-Combustion ignites itself by the very mechanism that produces knock? Knock occurs in spark-ignited engines because the end-gas is not burned until the flame front nears the cylinder wall and the whole combustion period is nearly over. It is the long heating of the end-gas that raises it to a chemical hairtrigger state, producing knock. In AR-Combustion, ignition occurs spontaneously at a multitude of sites throughout the chamber. There is no flame front compressing unburned charge. All parts of the charge advance together through the chemical reactions of burning. Because there is no end-gas subjected to long heating, there is no knock.

Emissions result from incomplete combustion. In conventional spark-ignited combustion, burning occurs during the tiny instant the flame front sweeps through a given element of fuel-air mixture. In this short time, some of the most complex fuel molecules may not burn completely. In ARCombustion, there is no flame front; instead, all parts of the charge change chemically together, so every charge element spends much longer in the combustion process.

One of the persistent problems of spark ignition is socalled “cyclic variation.” This means that the peak pressure of combustion, and the energy delivered to the piston, vary measurably from one cycle to the next-a result of differences in how fast the tiny, spark-initiated flame kernel grows into a flame front. Because the time of radical-initiated ignition depends upon average properties of the whole mixture, not upon accidents of in-cylinder turbulence, peak pressure is extremely consistent. This means that the average of all cycles is closer to the ideal than in spark ignition operation, and so efficiency and power generation are somewhat greater.

The likely fact is that EXP-2 is not just an alternative dirtbike. It is a signal, sent by Honda R&D to engineers everywhere, that life remains in the long-time dream of the late Mr. Honda himself; to stop pollution at its source in combustion, rather than to supinely accept exhaust emissions and try to clean them up with catalytic converter technology. The concepts behind AR-Combustion are known to be applicable to two-stroke, four-stroke and diesel engines. The EXP-2 may be just a novelty, an engineering exercise for a freshman class of Honda engineers. It may also be just the visible part of a much larger effort to achieve improved combustion in all types of engines.

Radical-initiated combustion has been ignored by major engine manufacturers for years as a far-fringe technology, not worthy of notice. Honda has now served notice that it has the R&D muscle to move forward where others deny that a way even exists. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontDoctor's Orders

February 1995 By David Edwards -

Leanings

LeaningsInvasion of the Midwestern Road Tester

February 1995 By Peter Egan -

TDC

TDCWeather

February 1995 By Kevin Cameron -

Letters

LettersLetters

February 1995 -

Roundup

RoundupYamaha's Tasty Trio For 1996

February 1995 By Robert Hough -

Roundup

RoundupBmw Scraps Its Triples

February 1995 By Robert Hough