TDC

Fighting friction

Kevin Cameron

IRON CYLINDER BORES HAVE BEEN WITH us a long time, and with good reason. Iron is a well-loved cylinder material because it is cheap, easily cast and machined, and naturally self-lubricating. The structure of cast iron is full of tiny pores containing graphite. Iron absorbs oil like a sponge, and graphite is a fine solid lubricant. Both stand ready to help if oil films fail-good seizure/galling insurance.

Piston and ring friction accounts for more than half an engine’s friction loss at midto high-speed operation. Most of that lost power is consumed in shearing the viscous oil films that support piston and rings for most of their travel up and down the bore. Viscosity is therefore both the cause of friction, and the quality that keeps the oil from instantly squeezing out from between moving parts. You can cut losses a bit by reducing oil viscosity while at the same time increasing parts smoothness so that the resulting thinner oil films can still do the job. This is how light-bodied synthetic oils cut friction losses in late-model engines.

You can cut friction another bit by systematically reducing parts weight; lighter pistons, ring packs and conrods load the main and rod bearings less, and generate less inertia force against the cylinder walls. Finally, you can cut down on the area of oil being sheared; slipper-skirt pistons can sometimes replace full-skirted designs for a small power gain. Narrower piston rings and rotating bearings work the same way. The game is to make each square inch of oil film carry as much load as it will bear. Careful, painstaking, detailed work of this kind has produced real gains in motorcycle engines over the past decade.

What do you do next? Well, too much oil on the cylinder walls costs power. When the tach is in the red zone and the piston is at 80 degrees ATDC, it hits that excess oil at something like 60 miles an hour. The more oil it hits, the more power is lost. All that’s needed is a nice, uniform film on the cylinder wall, enough to support the parts-nothing more. This ideal is easier to accomplish if oil likes the cylinder surface, adhering to it, spreading over it, even

penetrating into it.

An iron cylinder surface, then, is hard to beat, but alternatives exist. One is chromium, plated directly on aluminum. But unless it is etched or dimpled, chromium won’t allow oil to spread and form a film, and once the etched layer is worn away, its oilholding ability goes with it.

Now often preferred is the Mercedes-Mahle Nikasil process, where a thin plating of nickel contains five percent silicon carbide particles. After diamond honing, the silicon carbide has the form of millions of tiny, wear-resistant plateaus, sticking up slightly out of the nickel. Oil wicks into the crevices between. Such surface coatings and processes are attractive because: (1) They eliminate heavy iron liners; (2) being very hard, they wear slowly; (3) the .002-.005-inch thickness of plating transmits heat more easily than the traditional quarter-inch of iron; and (4) worn-out plated cylinders can be stripped and replated, if desired.

Combustion pressure is highest when the piston is near 15 degrees ATDC on the power stroke, but in motorcycle-sized engines, the piston has barely descended 2mm at this point. The top of the cylinder bore is hot, which causes the oil there to lose viscosity. This combination of high pressure, low velocity and high temperature causes piston rings to sink through their oil films and touch the cylinder walls hard for an instant before rising piston speed causes the rings to once again begin “surfing” on the oil. You see the accumulated result of this unlubricated operation as the “bell-mouthing” of the cylinder right at the top of ring travel.

Oil additives such as zinc dialkyldithiophosphate form sacrificial coatings on the metal parts. This reduces wear because these coatings are much weaker than the metal, and so absorb most of the welding, tearing damage of momentary metal-tometal contact. Plus, they are renewed each stroke by fresh oil (another reason to change oil frequently-the additives get used up in this process). Designers dream of oil-loving surfaces that never lose their slippery protection for even an instant, miraculously maintaining the oil film all the way to TDC and back.

New engineered cylinder materials try to combine iron’s self-lubricating ability with other desirable properties. In Honda’s fiber-reinforced metal process, felt-like cylindrical preforms made of combined aluminum oxide and carbon fibers are placed in the cylinder-block casting mold and aluminum is poured to fill the mold and impregnate the preforms. The result has the heat conductivity of aluminum, the wearresistance of the hard aluminum oxide ceramic, and-like iron-some of the self-lubricating properties of carbon.

At one time, chrome-on-aluminum cylinders were used only in high-cost applications, but the process later spread into production use. Then chrome was replaced by Nikasil as the favorite bore-plating process. The search continues for improved bore surfaces. These must have extreme hardness for low wear, yet somehow self-lubricate like iron, to fight friction and surface damage when local oil films fail. The microscopic surface profile must be extremely smooth, so that even the thin films resulting from use of lower-viscosity oils are enough to keep pistons and rings afloat.

Designers of F-l auto racing engines, long loyal to Nikasil, are now testing something beyond. Motorcycle engineers should be close behind. ®

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsUp Front

March 1992 By David Edwards -

Columns

ColumnsLeanings

March 1992 By Peter Egan -

Letters

LettersLetters

March 1992 -

Roundup

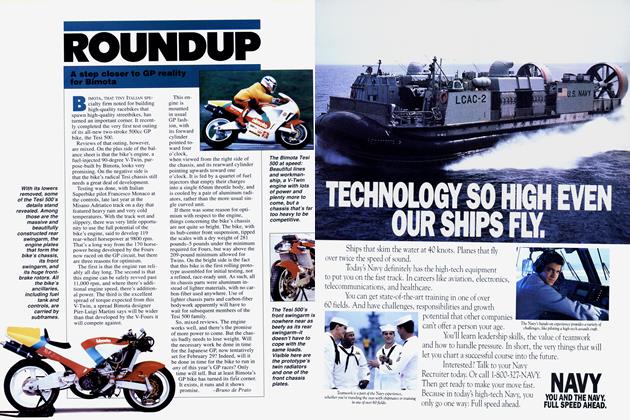

RoundupA Step Closer To Gp Reality For Bimota

March 1992 By Bruno De Prato -

Roundup

RoundupAmerica 1: Gold-Plated Superbike

March 1992 By Jon F. Thompson -

Roundup

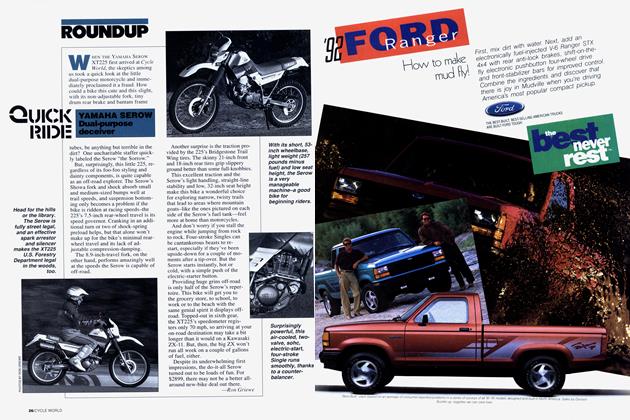

RoundupQuick Ride

March 1992 By Ron Griewe