SERVICE

DEPARTMENT

We welcome your technical questions and comments, and will publish those we think are of interest to our readers. Because of the volume of mail received, we cannot return any personal replies. Please limit your “Service” letters to technical subjects only, and keep them as brief as possible. Send them to: “service,” CYCLE WORLD, 1499 Monrovia Ave., Newport Beach, Calif. 92663.

SABRE SPEEDOMETERS

I have a 1982 Sabre and love it except for one problem. The 85 mph speedometer is useful only about two thirds of the time. Is there a way to modify it to read something more useful, like 125 or so?

Dave Munsinger

Mt. Prospect, III.

It’s possible to substitute the tach and speedo assembly from the 1983 Sabre in the 1982 Sabre housing. The part number for the instruments is 37200-MBO770 (HC 130876), and the suggested retail price is $126.49. The only complication arises because the gang plugs on the 1982 and 1983 instruments are shaped differently. However, the color coding on the wiring is identical, and, once the wires are connected, everything works. With some dexterity, patience, and a thin pen knife, the individual connectors can be removed from the plug bodies, and the connectors attached to the 1983 speedo wires can be inserted into the 1982 plug body. Alternatively, the gang plugs could be cut off and disposed, and individual connectors could be crimped onto the wires and used to tie the speedo into the wiring harness.

Another approach to obtaining a speedometer that covers the entire speed range of the motorcycle would be to have your 85mph speedo recalibrated. Moon Lite Ltd. (10 Meyer Ct., Hermosa Beach, Calif 90254, phone (213) 3741657) specializes in motorcycle speedometers, and can give most models a 140 mph speedo face for $79. Unfortunately, as this is written, the Sabre is one of the few models Moon Lite can't handle. That may change if someone loans them a Sabre for a few weeks so they can make the required jigs and recalibration studies, so it would be worth calling Moon Lite if you’re interested in the recalibration option.

H-2 EXPANSION CHAMBERS

In the Service column of your July issue a Kawasaki owner from Illinois requested help in finding expansion chambers for his H-2. You offered Wirgis Creative Performance and Bassani Mfg. as sources for these pipes. I realize both these manufacturers offer an excellent product. Bassani’s experience with the two-stroke engine is well founded and Bill Wirgis's Bonneville effort in the early 1970’s is legendary. However, I believe there is only one company currently involved in a development program for the Kawasaki Triples: Fast by Gast of 1930 Baseline Road, Grand Island, New York 14072.

Headed by Paul Gast, this business has based its reputation on building the fastest and quickest Triples in the country. N.M.R.A., I.D.B.A., and A M.A. Dragbike record books are filled with Fast by Gast performance standards.

So if the fellow from Illinois is really interested in the best equipment for his H-2, he has only to call Paul at (716) 773-1536.

Richard D. Winters Middleport, N.Y.

KX PLUG FOULING

I have a 1981 KX420 with a 443cc kit. The same problem with plug fouling occurs with my bike as on the KX you tested in April 1981, generally after about half an hour of riding. Have you found the source of the problem? Is there a cure?

Deane Romanoff

London, Ont.

Kawasaki is aware that plug fouling is a problem for at least some of the KX420s that have been sold, but notes that it seems to vary from bike to bike. Hie cause of the problem is simple; overly rich carburetion. Unfortunately the KX420s have a tendency to ping and detonate with leaner mixture settings. U.S. Kawasaki has experimented with alternate jetting for the bike, and has two recommended jetting packages that help the plug fouling problem. However, the Kawasaki representatives recommend at least 97 octane gasoline be used with either jetting package.

The best carburetion comes when the following parts are used: 162.5 main jet, 6F28-2 jet needle (the -2 indicates the second clip position from the top), R-6 needle jet, 2.5 slide cutaway, 17.5 pilot jet, and the air screw two turns out. The next best set-up has the advantage of using the stock slide cutaway: 167.5 main jet, 6F28-2 needle, S-2 needle jet (can be made by using a #35 drill in the standard R-8 needle jet), 25 pilot jet, and the air screw two turns out. Kawasaki says that either jetting combination will work with either the standard KX420 engine, or the 443cc kitted engine.

SERVICE FOR SEATS

One advantage to working in a neighborhood with lots of motorcycle-oriented business is that we can almost always find somebody who can do jobs beyond our own skills. One disadvantage is that we don’t always remember not everybody has this access.

Case in point, seats. Whenever a longterm bike or one of our own machines has a seat that doesn’t sit well, we visit the local upholstery store, where theyJ like motorcycles and are happy to rework the padding and whip up a new cover.

But. For as long as we’ve been doing this, we’ve heard from readers whose local shops are not willing to work on bikes, or don’t find the money worth it,.. Some styles, for instance touring seats, can be bought mail order, and some companies make new covers for torn stock ones. But truly custom seats, made for just the machine and the man who’lf ride it, are hard to find.

We’ve come up with two sources. Both^ are mail order only, that is, you send your old seat and they put the new padding and cover on your pan, exchange only, so you can count on parking the bike for a week or two. Both offer standard models, as in touring or road racing, and both will do a seat to your design and specification.

We have no firsthand experience with either firm. One made a seat for us but the bike was stolen the day after installation, so all we can say is, it looked nice and seemed comfortable but we cannot comment on durability.

We have heard good things secondhand, and both offer a catalog so you can at least take an informed guess.

The companies are:

Iron Horse

33 1 7 Warners Rd.

Route 173

Camillus, N.Y. 13031, and Superior Upholstery 4669 South Old 23 Brighton, Mich. 48116

RD350 TIPS

I am the owner of a 1975 Yamaha RD350B with a shade over 20,000 mi. on it. The bike is used mostly for regular transportation and one-up touring. Since many of its parts are up for replacement, I’d like to know the following: What front/rear spring combination would provide the best ride for touring type riding (I weight 230 lb. and carry about 25 lb. of miscellany)? Does anyone make a breakerless ignition for this machine? Will Lake injectors, or other floatless carburetors work on this machine? Finally is there a quartz halogen bulb that will fit the existing headlight? The diameter of the current sealed beam unit is approximately 63/s in., midway between the normal 53A in. and 7 in. headlights I see advertised.

As an aside, for any other RD owners who might be tempted to buy J. C. Whitney washable foam air cleaner kits (part number 02-2741N)—they are not custom fit, except that their i.d. is right for the o.d. of the carb. But (at least on my machine) they are too long. Worse, substantial rejetting is required if you don’t want to end up with holed pistons. I had to go from a 105 main jet to a 180, and the needle had to be raised a notch. I could have bought one hell of a lot of paper throwaways for the money I paid in learning this.

Dave Cunningham

Seneca Falls, N.Y.

It’s impossible to be precise with spring rates since a large amount of personal preference enters the decision, but we suspect 90 or 100 lb./in. rear springs used with the stock fork springs would be about right. Many companies at different times have made breakerless igni-

tion systems for RDs, but the only one that we know is still available is the Martek lOOOY. The Martek ignition is distributed by Rocky Cycle Co. and could be ordered through your local dealer. Lake injectors or other floatless carburetors could undoubtedly be made to work on a RD, but this modification just as certainly would not be worth the effort. The quartz halogen headlight required for the Yamaha has a diameter of 154mm, and can be obtained through Apogee Enterprises, Box 266-R, Sheboygan, Wis. 53081

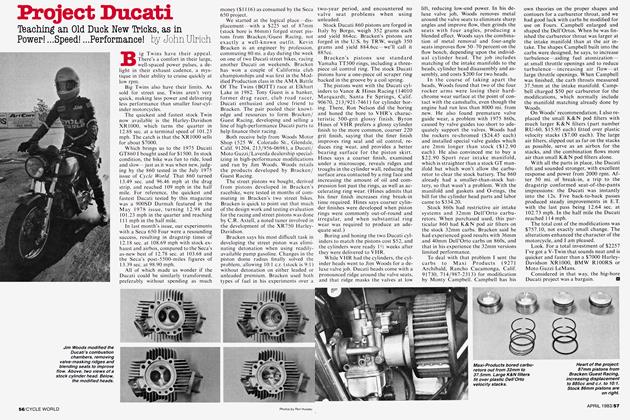

DUCATI PANTAH TIPS

Your effort to test the Ducati 600 SL Pantah should be commended since only a hundred or so of these little jewels have been imported. However, I wish you had taken the time to explore the performance potential so easily obtained from this engine design. While I agree that machines which are imported by the thousands and delivered to the customer virtually out of the crate should be tested just this way, your 600 Pantah should have been set up the way a savvy Ducati dealer would. For unobtrusive street riding, this involves a 42 tooth Circle Industries rear sprocket ($25), and K&N filters on the carb and breather ($20). Dropping the pilot jets two sizes from 65 to 55 ($4) will clear up most of your response and richness problems.

The glitch on your test bike at 5000 rpm will remain as a rich or lean stumble, depending on mixture setting, but only when you close the throttle at this engine speed in a corner, and then grab a handful coming out. Plug readings after changing the pilot jets as above will indicate that the main and needle jetting is spot on. I believe the problem is caused by too much accelerator pump delivery.

Since adjusting the pump is a real can of worms, lean out the slide from 60/3 to 70/3 by removing 0.7 mm from both slides. The mixture screw is a very sensitive adjustment and affects response way up into the mid-range. With these DelfOrtos you can ride the machine between 1500 and 5000 rpm and adjust the mixture (in for lean, out for rich), until an identical light tan plug reading is obtained for both cylinders. No more stumble, no more problems.

William G. Lamb

Allamuchy Township,N.J.

We're glad that you’ve set up your Pantah so it works well, but we wonder if a Ducati buyer should have to depend on such a savvy dealer. In any case,\ Ducati Pantah owners who are experiencing similar carburetion defects could try your modifications; the only recommendation we would make is that these changes shouldn’t be considered a cureall for all 600 Pantahs. From our conversations with Ducati owners and dealers, we’ve found that not all Pantahs carburet exactly the same (perhaps not all Pantahs came to the U.S. with the same jetting), so your fixes would only be applicable to Pantahs with the same problems.

BRAKE TESTS

In reading your January issue of Cycle World, I have a serious and curious question: how do you arrive at your braking distances? For instance, your article on the Yamaha XJ750RJ Seca shows a stopping distance of 127 ft. from 60 mph.

Several friends of mine took my 1981 GS850G with full Vetter set-up to our local airport for a brake test. The pavement was regular concrete as used on most freeways, and it was dry and clear of debris or oil. Temperature was 65°. I made four runs at exactly 60 mph, using a CMI radar unit to be accurate. Out of the four runs the best I could achieve without lock up of the rear wheel was 187 ft. Isn’t this much too far for a three disc modern superbike?

How do you do your brake tests? Do your testers use engine gears for partial braking? Do they pull in the clutch halfway through braking? Do they use the front brakes first, second, or simultaneously?

Patrolman Douglas GrindstafF

Fulton, Mo.

Our brake tests are performed at Orange County International Raceway where we do the rest of our performance tests. A dye marker gun is wired to the brake light circuit and attached to the bike. The bike is ridden up to the test speed at the far end of the drag strip (by this time the speedometer has been calibrated with the drag strip timing lights), and our rider stops the bike. After that we simply measure the distance between the dye spot on the pavement and the dye gun on the stopped bike. The best of three stops at each speed are reported in the road test.

There are probably several reasons for the discrepancies between our stopping distances and yours. If you applied the brakes at some specified spot, and then measured the distance from that spot to your bike, you probably added 15-30 ft. to your stopping distance. Why? In our tests we’re measuring the distance from the place the brakes are actually applied to the place where the bike stops. In yours, you’re including the distance covered during the few tenths of a second reaction time from when you see your braking marker to until you actually apply the brakes. Because 60 mph is 88 ft. I sec., that reaction time can add significant distance to a stop. Other reasons could be differences in surface, or that our brake test riders have more experience in making maximum effort stops. Engine braking isn’t used during our brake tests, both brakes are applied at the same time, it’s not uncommon to pull the clutch lever in, and the rear wheel is frequently locked for most of a 'stop.

Full dressers are the most difficult of all bikes to stop quickly. If you subtracted 25 ft. from your 187 ft. distance to allow for reaction time, the 162 ft. distance that results doesn’t seem unreasonable for your bike, though it might be bettered with practice. It’s worth considering, however, that our test rider is wearing full leathers during \the brake test. gj

Coming Next Month: Hie First Sports 750 Comparison. □ Honda Interceptor VF750F vs Kawasaki GPz750 vs Suzuki GS750E On Sale April 19 WORLD