Offset Crankpins Allow Honda's 45 V-Twin To Have Perfect Primary Balance, But Not Perfect Smoothness.

March 1 1983Offset Crankpins Allow Honda's 45 V-Twin To Have Perfect Primary Balance, But Not Perfect Smoothness. March 1 1983

Offset Crankpins Allow Honda's 45 V-Twin To Have Perfect Primary Balance, But Not Perfect Smoothness.

Engine smoothness is at the very heart of the Shadow’s engine design. To get an idea of the forces involved, imagine the piston from a normal 350cc Single. Fling it downwards in the bore at over 70mph and at the bottom of the bore yank it to an absolute stop. That stop would take about 2500 lb. of force, enough force to lift a small car. In an engine of this size that’s the force required to stop a normal piston and start it in the other direction, if the engine is spinning at 8000 rpm. This is the primary problem of engine balance, and it is known, appropriately, as primary balance. Every time the crank revolves, that piston exerts up to 2500 lb. of force in opposite directions.

One way to cancel that vibration is to put another, equally sized, piston opposite the first piston. With both pistons extending outwards and inwards together, the forces cancel themselves and the motor has perfect primary balance. That’s how a BMW works.

Another way to cancel that single cylinder’s imbalance is to put a large weight opposite the crankpin on the crankshaft. That’s a counterbalanced crankshaft. If the counterweight weighs as much as the piston and other reciprocating parts, and if it is positioned the same distance out from the crank center as the crankpin, then it acts much like that second piston in the BMW. The counterweight for a vertical Single would reach the bottom of its travel just as the piston hit the top. It would travel the length of the stroke upwards, just as the piston would travel the length of the stroke downwards. All the vertical forces from the counterweight and the piston would cancel.

The rub is that only the vertical forces would cancel. The piston in this vertical Single travels only up and down, and creates only vertical forces. The counterweight, though, moves side to side as well as up and down during its revolution, and creates horizontal forces just as large as its vertical forces. All the large counterweight has done is trade vertical vibration for horizontal vibration.

A 90° V-Twin takes advantage of that by adding a second cylinder 90° from the first. The piston forces in the vertical cylinder are cancelled by the up and down movement of the counterweight, and the piston forces of the horizontal cylinder are balanced by the counterweight’s fore and aft travel. The result is perfect primary balance, as demonstrated by Ducati V-Twins, which are very smooth running engines.

If you couldn’t add that second cylinder, the best compromise for the least vibration wouldn’t be the large counterweight, but a smaller counterweight only half as heavy (known as a 50 percent counterweight). Then, when the piston of our vertical Single was at the top of its stroke, requiring 2500 lb. of force to stop it and start it back down, the counterweight would cancel half that. A 1250 lb. force would remain, pointing up. Ninety degrees of crank rotation later, the piston would be coasting downward at its maximum speed, and would momentarily see no load. The counterweight, though, would be at the back of the crank, and would create 1250 lb. of force pointing back. After another 90° of crank rotation the piston would be at the bottom of its stroke, creating 2500 lb. of force directed down. Once again the counterweight would cancel half that, leaving 1250 lb. pointing down as the net load on the crank.

A pattern is emerging here: the combined effect of the 50 percent counterweight and the piston force is a constant force of 1250 lb. that changes direction with the crank rotation. The strange thing is how the force changes direction—it rotates at crankshaft speed in the opposite direction as the crank.

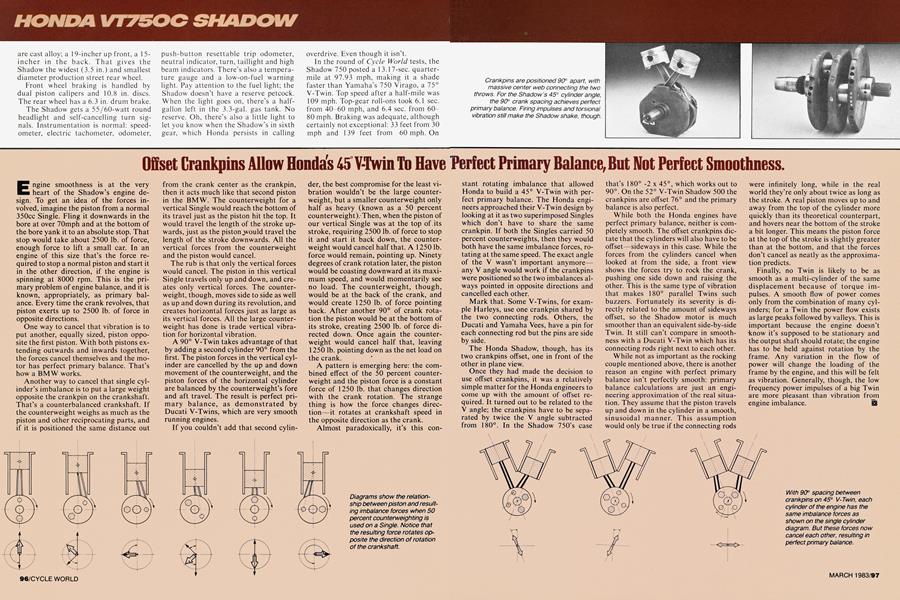

Almost paradoxically, it’s this constant rotating imbalance that allowed Honda to build a 45° V-Twin with perfect primary balance. The Honda engineers approached their V-Twin design by looking at it as two superimposed Singles which don’t have to share the same crankpin. If both the Singles carried 50 percent counterweights, then they would both have the same imbalance forces, rotating at the same speed. The exact angle of the V wasn’t important anymore— any V angle would work if the crankpins were positioned so the two imbalances always pointed in opposite directions and cancelled each other.

Mark that. Some V-Twins, for example Harleys, use one crankpin shared by the two connecting rods. Others, the Ducati and Yamaha Vees, have a pin for each connecting rod but the pins are side by side.

The Honda Shadow, though, has its two crankpins offset, one in front of the other in plane view.

Once they had made the decision to use offset crankpins, it was a relatively simple matter for the Honda engineers to come up with the amount of offset required. It turned out to be related to the V angle; the crankpins have to be separated by twice the V angle subtracted from 180°. In the Shadow 750’s case that’s 180° -2 x 45°, which works out to 90°. On the 52° V-Twin Shadow 500 the crankpins are offset 76° and the primary balance is also perfect.

While both the Honda engines have perfect primary balance, neither is completely smooth. The offset crankpins dictate that the cylinders will also have to be offset—sideways in this case. While the forces from the cylinders cancel when looked at from the side, a front view shows the forces try to rock the crank, pushing one side down and raising the other. This is the same type of vibration that makes 180° parallel Twins such buzzers. Fortunately its severity is directly related to the amount of sideways offset, so the Shadow motor is much smoother than an equivalent side-by-side Twin. It still can’t compare in smoothness with a Ducati V-Twin which has its connecting rods right next to each other.

While not as important as the rocking couple mentioned above, there is another reason an engine with perfect primary balance isn’t perfectly smooth: primary balance calculations are just an engineering approximation of the real situation. They assume that the piston travels up and down in the cylinder in a smooth, sinusoidal manner. This assumption would only be true if the connecting rods were infinitely long, while in the real world they’re only about twice as long as the stroke. A real piston moves up to and away from the top of the cylinder more quickly than its theoretical counterpart, and hovers near the bottom of the stroke a bit longer. This means the piston force at the top of the stroke is slightly greater than at the bottom, and that the forces don’t cancel as neatly as the approximation predicts.

Finally, no Twin is likely to be as smooth as a multi-cylinder of the same displacement because of torque impulses. A smooth flow of power comes only from the combination of many cylinders; for a Twin the power flow exists as large peaks followed by valleys. This is important because the engine doesn’t •know it’s supposed to be stationary and the output shaft should rotate; the engine has to be held against rotation by the frame. Any variation in the flow of power will change the loading of the frame by the engine, and this will be felt as vibration. Generally, though, the low frequency power impulses of a big Twin are more pleasant than vibration from engine imbalance.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontFor Adults Only

March 1983 By Allan Girdler -

Letters

LettersLetters

March 1983 -

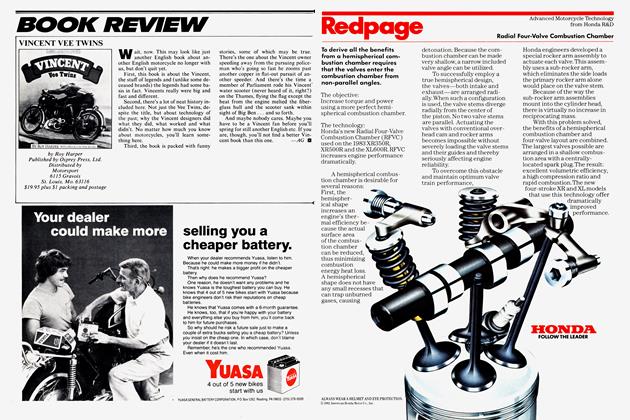

Book Review

Book ReviewVincent Vee Twins

March 1983 By AG -

Departments

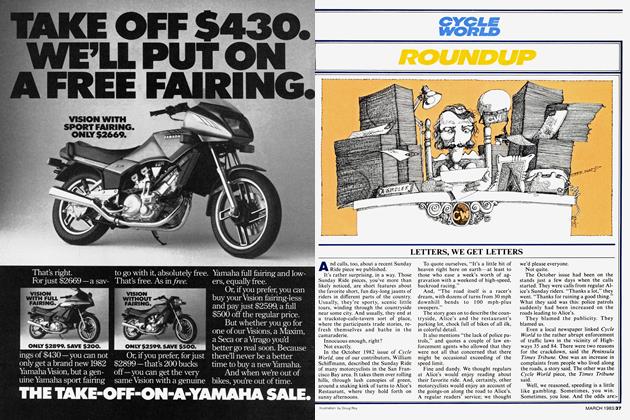

DepartmentsRoundup

March 1983 By James F. Quinn -

Features

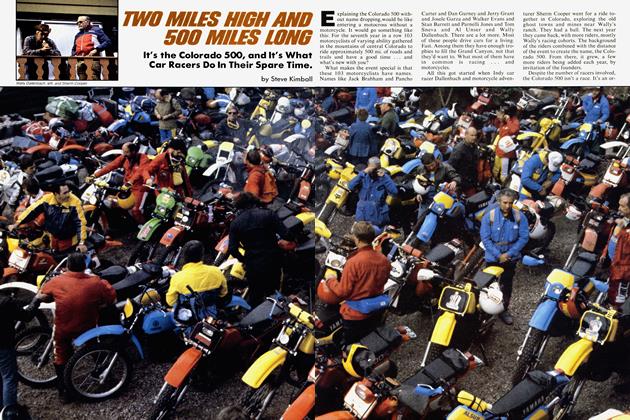

FeaturesTwo Miles High And 500 Miles Long

March 1983 By Steve Kimball -

Technical

TechnicalSouping the 650 Seca

March 1983 By John Ulrich