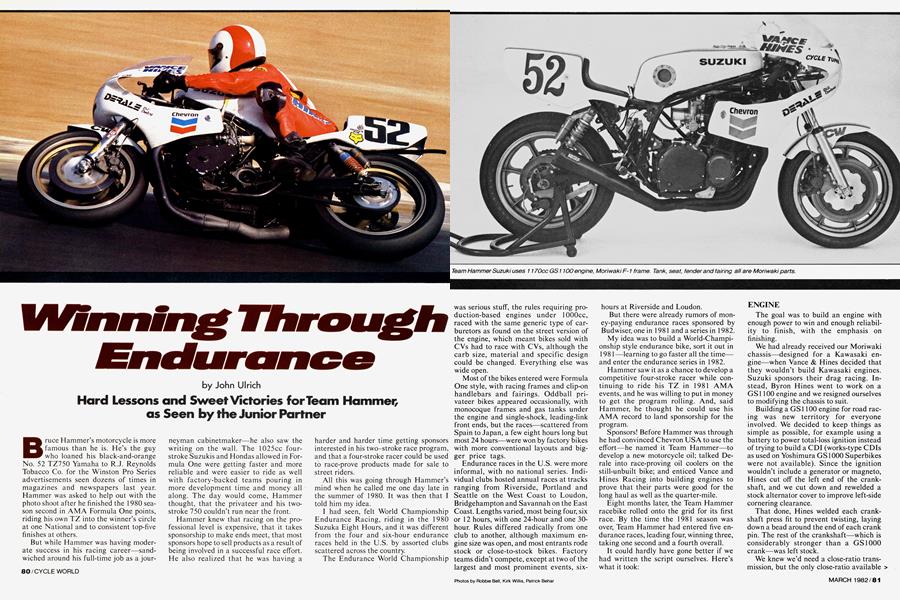

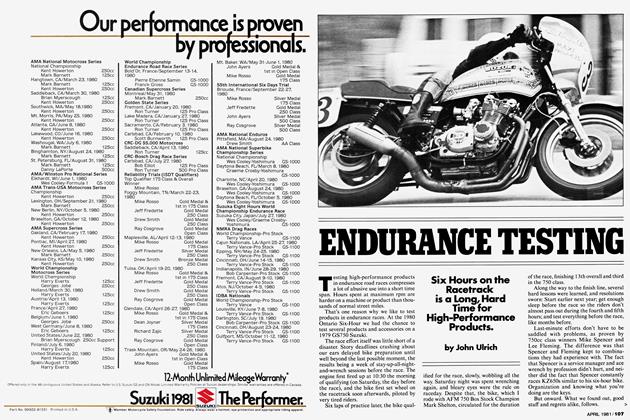

Winning Through Endurance

John Ulrich

Hard Lessons and Sweet Victories for Team Hammer, as Seen by the Junior Partner

Bruce Hammer's motorcycle is more famous than he is. He's the guy who loaned his black-and-orange No. 52 TZ750 Yamaha to R.J. Reynolds Tobacco Co. for the Winston Pro Series advertisements seen dozens of times in magazines and newspapers last year. Hammer was asked to help out with the photo shoot after he finished the 1980 season second in AMA Formula One points, riding his own TZ into the winner’s circle at one National and to consistent top-five finishes at others.

But while Hammer was having moderate success in his racing career—sandwiched around his full-time job as a journeyman cabinetmaker—he also saw the writing on the wall. The 1025cc fourstroke Suzukis and Hondas allowed in Formula One were getting faster and more reliable and were easier to ride as well with factory-backed teams pouring in more development time and money all along. The day would come, Hammer thought, that the privateer and his twostroke 750 couldn’t run near the front.

Hammer knew that racing on the professional level is expensive, that it takes sponsorship to make ends meet, that most sponsors hope to sell products as a result of being involved in a successful race effort. He also realized that he was having a harder and harder time getting sponsors interested in his two-stroke race program, and that a four-stroke racer could be used to race-prove products made for sale to street riders.

All this was going through Hammer’s mind when he called me one day late in the summer of 1980. It was then that I told him my idea.

I had seen, felt World Championship Endurance Racing, riding in the 1980 Suzuka Eight Hours, and it was different from the four and six-hour endurance races held in the U.S. by assorted clubs scattered across the country.

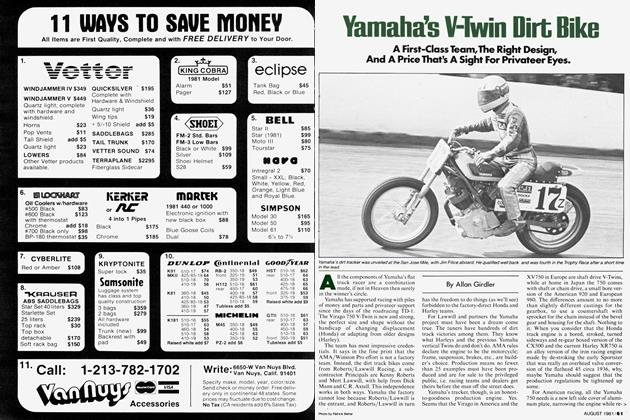

The Endurance World Championship was serious stuff, the rules requiring production-based engines under lOOOcc, raced with the same generic type of carburetors as found on the street version of the engine, which meant bikes sold with CVs had to race with CVs, although the carb size, material and specific design could be changed. Everything else was wide open.

Most of the bikes entered were Formula One style, with racing frames and clip-on handlebars and fairings. Oddball privateer bikes appeared occasionally, with monocoque frames and gas tanks under the engine and single-shock, leading-link front ends, but the races—scattered from Spain to Japan, a few eight hours long but most 24 hours—were won by factory bikes with more conventional layouts and bigger price tags.

Endurance races in the U.S. were more informal, with no national series. Individual clubs hosted annual races at tracks ranging from Riverside, Portland and Seattle on the West Coast to Loudon, Bridgehampton and Savannah on the East Coast. Lengths varied, most being four, six or 12 hours, with one 24-hour and one 30hour. Rules differed radically from one club to another, although maximum engine size was open, and most entrants rode stock or close-to-stock bikes. Factory teams didn’t compete, except at two of the largest and most prominent events, sixhours at Riverside and Loudon.

But there were already rumors of money-paying endurance races sponsored by Budwiser, one in 1981 and a series in 1982.

My idea was to build a World-Championship style endurance bike, sort it out in 1981—learning to go faster all the time— and enter the endurance series in 1982.

Hammer saw it as a chance to develop a competitive four-stroke racer while continuing to ride his TZ in 1981 AMA events, and he was willing to put in money to get the program rolling. And, said Hammer, he thought he could use his AMA record to land sponsorship for the program.

Sponsors! Before Hammer was through he had convinced Chevron USA to use the effort—he named it Team Hammer—to develop a new motorcycle oil; talked Derale into race-proving oil coolers on the still-unbuilt bike; and enticed Vance and Hines Racing into building engines to prove that their parts were good for the long haul as well as the quarter-mile.

Eight months later, the Team Hammer racebike rolled onto the grid for its first race. By the time the 1981 season was over, Team Hammer had entered five endurance races, leading four, winning three, taking one second and a fourth overall.

It could hardly have gone better if we had written the script ourselves. Here’s what it took:

ENGINE

The goal was to build an engine with enough power to win and enough reliability to finish, with the emphasis on finishing.

We had already received our Moriwaki chassis—designed for a Kawasaki engine—when Vance & Hines decided that they wouldn’t build Kawasaki engines. Suzuki sponsors their drag racing. Instead, Byron Hines went to work on a GS1100 engine and we resigned ourselves to modifying the chassis to suit.

Building a GS1100 engine for road racing was new territory for everyone involved. We decided to keep things as simple as possible, for example using a battery to power total-loss ignition instead of trying to build a CDI (works-type CDIs as used on Yoshimura GS1000 Superbikes were not available). Since the ignition wouldn’t include a generator or magneto, Hines cut off the left end of the crankshaft, and we cut down and rewelded a stock alternator cover to improve left-side cornering clearance.

That done, Hines welded each crankshaft press fit to prevent twisting, laying down a bead around the end of each crank pin. The rest of the crankshaft—which is considerably stronger than a GS1000 crank—was left stock.

We knew we’d need a close-ratio transmission, but the only close-ratio available was designed for a GS1000. We bought two, used, from Yoshimura R&D, then took them apart and sent them out to be magnafluxed, an inspection process that reveals cracks or other defects.

To our dismay, two of the four shafts and four gears were cracked, and the press-fit second gear had been spinning on each main shaft. Fortunately, Yoshimura traded us new parts for the broken pieces.

The next problem was fitting the transmission into the cases. The GS1100 mainshaft is longer than the equivalent GS 1000 shaft, since the stock GS 1100 has wider gears than the GS1000.

Although there was enough shaft/bearing engagement, the bearing shoulder on one end of the close-ratio mainshaft didn’t . quite reach the outboard bearing in the GS1100 cases, leaving about 3mm of end play in the assembly. So Hines made a spacer to fit between the bottom of the bearing hole in the cases and the end of the shaft, holding end play down to 0.010 in. Then Hines shimmed the gears so they lined up correctly with the shift drum, and so that in neutral, the spaces between the gears on each shaft were equal.

Unlike the stock transmission, the closeratio transmission doesn’t have pressurefed oiling to the shift fork grooves, and that can cause the fork ends to gaul and hang up. To cure that problem, Hines drilled small holes in the oil gallery lo-

. cated in the cases just above the transmission. With the engine running, the holes sprayed oil onto the transmission, lubing the shift forks and grooves.

The next step was to reinforce the clutch hub, which often fails in drag racing and hard street use. The modifications included heavy-duty rivets, stronger springs and steel tabs to keep the backing plate from flexing. The clutch was equipped with stock fiber plates, Barnett copper-coated steel plates, and heavyduty springs.

Hines machined a set of Wiseco 76mm forged pistons with high domes to bring displacement up to 1198cc and compression up to 11:1, then notched the dome at each corner to allow use of the stock composite GS1100 head gasket, which is less prone to leak oil than an all-copper gasket. The standard Wiseco ringkit used on each piston included a tool-steel top ring, a taper-faced iron second ring, and threepiece oil control ring. Piston clearance was set at 0.001 in. at the bottom of the skirt. Hard-chromed wrist pins (resistant to gauling) were held in place with aluminum-alloy buttons instead of circlips.

The high compression meant the bike would have to be run on 110 octane racing gas.

The cylinder head was ported, with the intake tracts roughed up to improve fuel atomization, and the stock valves were swirl polished. VHR racing valve springs were installed.

Experience had shown Hines that accelerated cam follower wear often follows the installation of stronger valve springs. To prevent that problem, the rocker arms were hardened and the oil pump gear was replaced with a gear from a plain-bearing GS750. The new oil pump gear increased oil flow to the cams and followers (as well as other pressure-fed engine parts) by about one third.

The cams opened the intake valves 13 ° BTDC and closed them 53° ABDC. The exhaust valves were opened 53° BBDC and closed 13 ° ATDC. Lift for both intake and exhaust valves was 8.76mm.

The cam chain tensioner was modified from being automatic to manual-lock, since automatic tensioners can back off when the throttle is closed at high rpm.

Keihin 31mm CR carburetors were chosen because we had road racing experience with them, they flowed well, and the throttle return spring was exceptionally light, a consideration that becomes more important in long races. Stiff throttle springs can make the rider’s wrist and shoulder hurt, a nuisance at best and a distraction at worst.

The exhaust system head pipes came right off one of Terry Vance’s drag bikes, and were heated and bent to line up with a new collector and megaphone routed underneath the engine for maximum cornering clearance.

The modifications were completed a few days before the bike was scheduled for its first track test, and there was no time to send the engine parts out for treatment with Kal-Gard gun coat, a thin, black coating which improves heat transfer from hot engine parts to cooling air.

The next best thing, Hines decided, was to spray-paint the engine black,which we did.

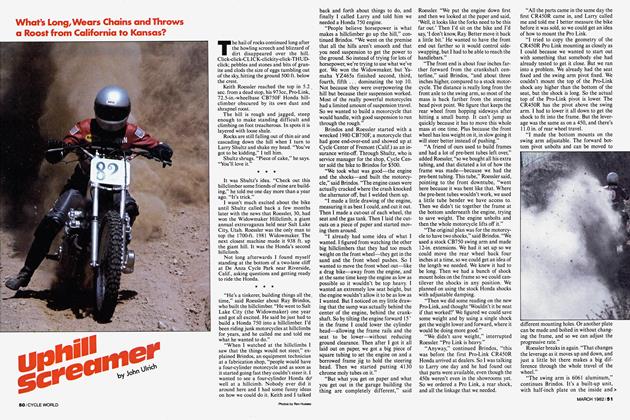

The first two test sessions—consisting of a couple of sprints at a Sears Point club race, followed the next day by five hours of continuous running and oil sampling at Laguna Seca, rented for the occasion by Chevron—showed that the suspension and gearing weren’t even close, but that the engine was producing lots of power.

Too much power. More accurately, too much power too abruptly. It pulled well enough in the middle, but when the tach hit 8000 rpm all hell broke loose, the rear wheel lighting up instantly. If the rider had the thing pointed in the right direction and fairly upright, it wasn’t too bad, although it wheelied a lot. But if the bike was still leaned over and came on the cams, it went sideways. Up the back side of the course, the bike stood straight up in fifth gear at the crest of a hill leading into the corkscrew.

But it lived. When the engine was torn down the next day, all the parts looked good, except the wrist pin buttons, which showed significant wear. Hines was elated.

He also listened to our complaints about power delivery and decided to advance the intake cam 4°, changing the timing from 13-53 to 17-49. That small change, Hines said, would boost cylinder pressure at low rpm and move the power band down, so the bike would, in theory, come off the turns smoother with controllable, strong power all the way up to the 11,000 rpm redline. We’d know for sure at the first race, picked to mesh with Hammer’s AMA schedule, now just a few weeks away. In the meantime, the engine was reassembled without the internal parts, but with gaskets in place, and sent to KalGard for sand blasting and gun coating.

The exhaust ports had been sealed off with fabricated plates and several layers of duct tape held in place by the rubber carburetor manifolds sealed the intake ports. Duct tape also sealed the breather openings, and the transmission countershaft was left installed to seal its opening in the cases.

Still, when the engine returned from Kal-Gard, red abrasive grit had been blasted through the multiple layers of duct tape sealing several openings, and the stuff was everywhere inside the cases. Cleanup was a major and time-consuming project, critical because even a little abrasive could quickly ruin the internal parts during a race.

We didn’t know it at the time, but the fact that the carburetor boots had been cooked (Kal-Gard is baked after being sprayed on) was a more serious problem. We should have installed new boots, but didn’t.

Because one hour into a four-hour endurance race in Savannah, Georgia, the carburetors fell off while Team Hammer led by 2Vi minutes. The baking had made the manifolds stiff and hard, and the carbs worked loose and finally popped off when the engine spit back while being pushstarted after a pit stop. It took 13 minutes to chug around the track on one cylinder, holding one carb tight against its manifold, and to make repairs. We never made it up, finishing fourth overall. Happily the bike ran perfectly, had an excellent powerband and great top speed. It also vibrated terribly, and one of the aluminum front engine mount plates was cracked after the race.

We were worried when we checked the oil level the next morning and found that the bike had used 3.0 pints, and the worry turned to horror when we added oil and started the bike, hearing awful, rattly piston noise. Hammer rode the bike in sprint races that day anyway, testing suspension, and it was still faster than several AMA Superbikes at the track.

But back in California at VHR, a teardown revealed that the pistons had all seized, serious black and gray smears defacing the skirts.

Hines wasn’t sure what caused the seizure. The pistons were sent to the Chevron lab for analysis with an electron scanning microscope. In the meantime, Hines decided to back off the power a notch and we decided that oil would have to be added to the bike every hour during races.

There were other problems. The cam chain tensioner shoe had cracked and broken, and the shoe support had snapped where the assembly bolted to the cases. All the exhaust valves were rusted into their guides, and the cylinder bores and rings were rusted. Hines said it was essential to spray the valve stems and the cylinders (through the spark plug holes) with WD-40 or Bel Ray 6-in-1 or Kal Gard 30-30 after every day of riding the bike, be it practice or racing, to avoid rusting.

For the next race, a six-hour at Riverside, Calif., Hines put the engine together with 75mm Wiseco pistons with flat domes, reducing displacement to 1170cc and c.r. to 10.3:1. He also drilled two 0.193-in. oiling holes in each piston skirt, front and rear.

To reduce the engine vibration reaching the rider, Hammer made new front engine mount plates out of '/s-in. steel and welded on rubber mount carriers off a prototype Suzuki GS650 he found parked in the back of the Vance & Hines pipe-fitting room. (GS650s sold to the public came without rubber mounts).

A few days before the race, the lab report from Chevron came back, stating that the seizure in Georgia was caused by lack of oil in the engine, not excessive heat. The lab report also showed no breakdown of the 15w-50 Chevron oil used in the race, which meant that the compact all-copper Derale cooler was doing its job.

An oil quick-fill was still needed to keep engine oil levels up during races, and Derale provided quick-connect/quick-release fittings. We sent the fittings to a manufacturer of gasoline quick-fills and ordered a 1-qt. aluminum oil quick-fill designed to blast oil into the engine with air pressure. The night before the race, however, the quick-fill manufacturer admitted that he couldn’t finish the project. We took back the fittings and Monty Campbell of Maxi Products worked late into the night to build a suitable quick-fill out of an aluminum bottle normally used by backpackers to carry stove fuel. Since then, Campbell has gone into production of oil quick-fills, installing quick-connect fittings and a tubeless-tire valve stem to empty propane bottles. The completed oil quick-fills hold a pint of oil and, with 50 psi of air, will empty into an engine in 2.5 sec.

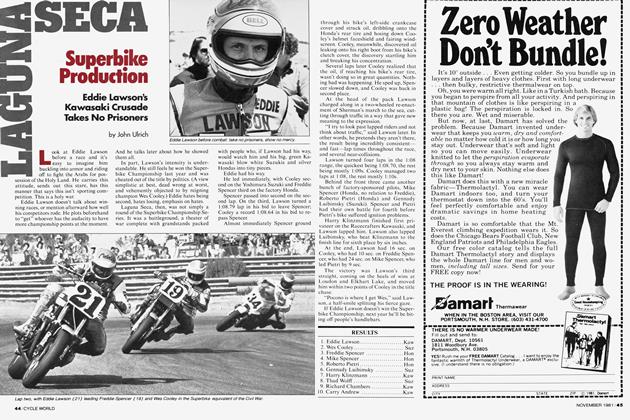

The engine performed well in the race, although it was a little slower than in Georgia, carrying us to second overall behind Kawasaki works riders Eddie Lawson and Ron Pierce. The new rubber mounts cut vibration by about 90 percent , making it easier to ride the bike. The oil quick-fill was used to blast in a pint of oil at every pit stop, and the engine finished with plenty of oil in the crankcase.

But it also finished with wrist pin buttons almost completely worn away, and with two broken bolts lying in the oil sump. The bolts normally held the cases together around the crankshaft, and are reached with the oil pan off. During the race the bolts vibrated and worked and finally snapped.

The oil drained from the bike looked like silver paint because it held so much aluminum from the nearly-disintegrated wrist pin buttons, and the cam chain tensioner shoe was worn again. But lab tests showed that the oil hadn’t broken down. Pistons, cams, rocker arms, clutch and other parts were all in good shape. Oiling down the valve stems and cylinders after the race prevented rusting.

Hines hadn’t seen wrist pin button wear like this in any drag or street bike. He theorized that the combination of high heat, high engine speed and high loading was just too much for the aluminum alloy in the buttons. To cure the problem, he ordered buttons of a better, harder grade of alloy.

The next stop was a four-hour at Bridgehampton, New York. It rained for half the race. The key to staying upright was avoiding full throttle except when in fourth and fifth gears on the straightaway. The combination of relatively easy riding and cooling rain left internal parts looking like new afterwards.

At Elkhart Lake, Wisconsin for another four-hour, however, some of the old problems and a few new ones popped up. It rained there, too, and about the time it started to rain the bike began running on three cylinders, making power delivery perfect for the wet track. Surprisingly, the three-cylinder GS 1100 was still the fastest bike in the race. The problem was later traced to a fractured ignition coil, which had been vibrating against the frame.

Case bolts broke in Wisconsin, too, one of them taking an inch-square piece of crankcase webbing with it. The cam chain tensioner shoe was junk again. Transmission gears showed severe wear, the culmination of the strain of four races, and the shift drum was hammered with dents in its shift fork tracks. All race long, the bike had jumped out of second gear when revved over 8000 rpm, due to shift drum damage. We won anyway.

Hines was mystified by the shift drum damage until Hammer admitted that he had been downshifting without the clutch, a technique he learned on his TZ. As for the transmission damage, short of having gears custom-made out of better material, the only cure was to replace parts after every other race.

The final event for the season was a sixhour on the tight, twisty Loudon track, where acceleration off corners was more important than straightaway speed. The bike worked perfectly, and Team Hammer won again. The only engine part damaged in the event was the cam chain tensioner and another case bolt. The wrist pin buttons looked good and Hines decided to put the harder pins in all Vance & Hines piston kits.

To cure the engine problems for 1982, Hines made chrome-moly studs to replace the problematic case bolts, and fabricated a sheet steel sheath to spread the load from the cam chain tensioner plunger across more of the back side of the tensioner shoe. Harder transmission gears have been ordered. With those changes, Hines is confident that he can go back to the 1198cc, 11:1 configuration and retain reliability.

CHASSIS

Converting the Moriwaki chassis to accept the GS1100 engine required building and installing new engine mounts, but the structural frame members weren’t altered. Rob North, a frame builder in San Diego, Calif., did the work.

Sorting out the suspension wasn’t as simple, It took all season to get the bike handling well, with improvements madeat every race.

Over the course of the season, the front end was gradually lowered (by sliding the 36mm Kayaba racing fork tubes up in the triple clamps) and the rear end raised (by using longer shocks). Hammer constantly fiddled with shock damping, shock springs, shock spring preloads, fork oil weights, fork oil levels, and fork air pressure.

Little by little, changes made through trial-and-error testing tuned out bump-induced wobbles in fast sweeping turns and eliminated most front tire chatter, although the single biggest improvement in chatter reduction came at Loudon, from switching from a Goodyear to a Dunlop front slick, which' we obtained through friends in Europe.

It was never perfect, and the biggest problems were encountered with the shocks. We picked MX Fox Superbike Shox because they promised a wide range of possible adjustments in rebound and compression damping, although changing settings requires disassembly..The shocks, which feature a piggyback oil reservoir with a nitrogen-backed diaphragm to prevent oil foaming, must be pressurized with nitrogen upon reassembly.

As delivered, the shocks were radically over-damped and over-sprung, and the softest springs sent with the shocks were still too stiff. By the end of the season MX Fox had delivered softer springs, a 119 lb. 2.75-in. spring and a 126 lb. 7.5-in. spring, one of each used in combination on each shock body.

Damping settings in the MX Fox shocks are adjusted by replacing jets and using washers of various thicknesses. The washers are located over various valving holes in the shock piston assembly, and to move through the valve holes, oil in the shock must flex the washers upward, out of the way. Changing the thickness of the washers over the valves changes the amount of resistance to oil movement, which controls damping. We settled on No. 104 low speed rebound damping jets, (producing the lightest possible rebound); No. 11 high speed rebound damping washers (which is near the upper end of the 1-14 range); and No. 0 low speed compression washers and No. 3 high speed compression washers, the softest settings. Shock oil was Bel-Ray LT-100, recommended by MX Fox and the equivalent of a 5w. Nitrogen pressure was set at 200 psi.

With those settings, the shocks worked better. After the 1981 season ended MX Fox tests showed that the No. 0 low speed compression washer was too flexible to return to position after being moved by the oil, in effect floating while the shock worked. The problem wasn’t encountered before because motocrossers never use the No. 0 washer, and MX Fox shocks originally were made for motocross bikes. A design change in internal valving has been made and can be retrofitted to shocks sold for road racing use in 1981.

The forks were run with 5 psi air pressure and the springs and pre-load spacers they came with. Actual fork action was better—producing less chatter—with 0 psi, but then the bottom engine mounts dragged too easily in turns. The 5 psi setting was a compromise made to increase ride height and cornering clearance.

The suspension changes lowered the bike, and as a result the cut-down alternator cover touched down too soon in corners. So it was replaced with a flat plate with a snout welded on to allow room for the stub of the crankshaft.

continued on page88

continued from page 85

WHEELS AND BRAKES

Hammer had good results with Morris magnesium racing wheels in the past so we ordered three WM-4 18 fronts and three WM-8 18 rears. Having three sets of wheels would allow us to have an extra set in the pits with tires identical to those on the bike, and another set ready with tires suitable for a weather change.

We hoped installing a cush drive on each rear wheel would prolong transmission life. Morris made the aluminum cast wheels on the 1976 Kawasaki LTD 900, those wheels accepting a bolt-on cush drive manufactured by Kawasaki in Japan. So we bought three complete cush drives from a local Kawasaki shop and had the wheels machined to fit.

The cush drives were heavy, but we figured that carrying weight was better than blowing up transmissions.

. Brakes made of cast iron with aluminum carriers came from Kosman Specialities. The fronts measured 13-in. and were held to the carriers with floating mounts to allow side-to-side movement in an effort to reduced warping. The rear wheel disc measured 10 in. and mounted rigidly to its carrier. Lockheed calipers were used all around, and Rob North made caliper hangers out of magnesium. The front master cylinder came off a GS1100, the rear from a TZ750, with braided steel lines from Earl’s Supply. Front pads were Ferodo 2447s, (changed after every other race) with Ferodo DSI 1 rear pads.

After the first race the wheels and brake pads were modified to make wheel changes easier. The Kayaba forks came with Kawasaki KZ1000 axle clamps, which tighten around a dual-nut axle already assembled to the wheel. So each front wheel was prepared with its own set of axle, spacers and nuts. Then, replacing the front wheel required working just the four * axle clamp nuts, easy for two men with air wrenches.

But the front discs hung up on the brake pads as they slid onto the calipers. To prevent that problem, we beveled the leading edge of each pad to guide the incoming disc between the pads.

The rear pads were also beveled on the edges. Loose spacers presented another problem. The rear wheel installation used three spacers, one on each side of the hub and another between the brake hanger and the swing arm. Extra spacers were made and secured to each rear wheel. The spacer on the cush-drive side was machined with a ridge on one end, which

*

pushed into the wheel bearing grease seal and was held by the seal lip. The spacer on the brake side was also machined with a lip, secured by a plate bolted to the disc carrier. The third spacer was secured to the caliper hanger with two screws.

That done, no spacers fell out when the rear wheel was removed.

The frame came with neat wheeled stands made by Moriwaki, which allowed either or both wheels to be raised off the ground almost instantly. Using the stands, grabbing a handle welded to the rear axle head and removing the axle nut with an air wrench, two men—after practicing— could change the rear wheel in less than one minute. A front wheel change took 30 sec.

A seven-man crew provided by Cycle Tune won the pit crew competition at the Riverside race by changing both wheels, filling the gas tank, adding oil, adjusting and lubing the chain, changing the battery and cleaning the windscreen in 1 min., 10 sec.

FUEL CAPACITY AND REFUELING

The Riverside stop wouldn’t have been so fast if Team Hammer didn’t have quick-fill equipment for refueling. Depending upon the race, we used either Hammer’s 35-gal. Daytona-type tower quick fill or an 8-gal. dump can built by Moriwaki.

The tower was faster but required two men to operate and it took up more room in the truck. The dump can was easier to transport, could be handled by one man and used the tank’s aircraft refueling cap.

The bike ran with a 6.0-gal tank at the first race. For Riverside we fitted an 8.0gal. tank made to order by Moriwaki. It was just as narrow as the smaller tank, but was several inches taller, not only allowing a bigger load of fuel but also making it the perfect height for the rider to lay his chest on, lessening wrist and arm strain and making the bike more comfortable to ride.

We considered using the larger gas tank to run the bike 1.5-hr. between pit stops, but decided against it because the bike was demanding enough to ride for one hour. The trade-off of carrying extra gas (and weight) was a small price to pay for improved comfort—which made it easier to maintain concentration—during races.

Both tanks used standard KZ1000 petcocks, famous for poor fuel flow. Monty Campbell of Maxi Products drilled out the petcock passageways to increase flow by a third,eliminating any chance of fuel starvation on long straightaways.

MISCELLANEOUS

Early test sessions left us with batteries that sulfated after one day of testing unless immediately recharged. So we tried various brands of batteries and settled on

Wisco batteries made by Exide. Each battery was fitted with dual-lead, quickchange connectors and held in the aluminum battery tray with a Velcro strap.

Drive chains weren’t a problem. We started the season using Diamond XDL 630 O-ring chain and still used it five races later, installing new chains before Riverside and Loudon. The chain fitted for Riverside was also used at Bridgehampton and Elkhart. Chain adjustments were made mid-way through each race, with lube sprayed on at every other pit stop.

Rear wheel sprockets were aluminum from Circle Industries, and typically lasted two races. New sprockets were used each time the chain was replaced.

Besides installing new rubber intake manifolds and heavy-duty hose clamps after the Georgia race, we used twisted stainless steel safety wire and plastic tiewraps to secure the bank of carburetors to the cylinder head and upper frame rails.

At Riverside, one of the upper shock mount bolts fell out despite being safetywired in place. In the following races all nuts and bolts on the chassis were installed with Loctite.

The rear brake master cylinder malfunctioned at the first race, causing the brake to lock. After practice at Riverside, a new master cylinder cured the problem.

The ignition system used stock GS1100 trigger, advance mechanism and coils, with a works Suzuki control box donated by Pops Yoshimura. The advance unit, however, was welded in the full-advance position. Spark plugs came from ND and were changed before every race.

Monty Campbell lent us a set of 34mm Keihin carburetors with accelerator pumps, which he converted from a stock set of 1978-79 sohc CB750F carbs. Campbell’s Maxi-Bore carbs flowed more air than our CRs, but needed a stronger return spring due to larger and heavier slides, the accelerator pumps, and assorted linkage. The spring was too strong for extended use without causing a sore right wrist, and the bike started every race with the CR carbs.

Those CR carburetors were improved, however, with the installation of a slowspeed circuit by Whitney Blakéslee of Champion Motorcycles. By the end of the season Blakeslee had become the exclusive Moriwaki importer for the U.S. and founded a new company, Champion Moriwaki USA, which began selling—among other things—Moriwaki chassis like ours.

THE FUTURE

Chevron liked Team Hammer’s results in 1981 and signed up again for 1982, as did Vance & Hines and Derale. The team will contest a new national endurance series sponsored by Budweiser, and Hammer will race a 1025cc Katana engine at Daytona. Y’all come and see us.